Method for removing pole piece coating and pole piece coating cleaning device

A technology for cleaning devices and pole pieces, which is applied in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the problems of thermal deformation of light foil, oxidation of foil surface, inability to effectively collect dust particles, etc., and achieve the effect of preventing stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

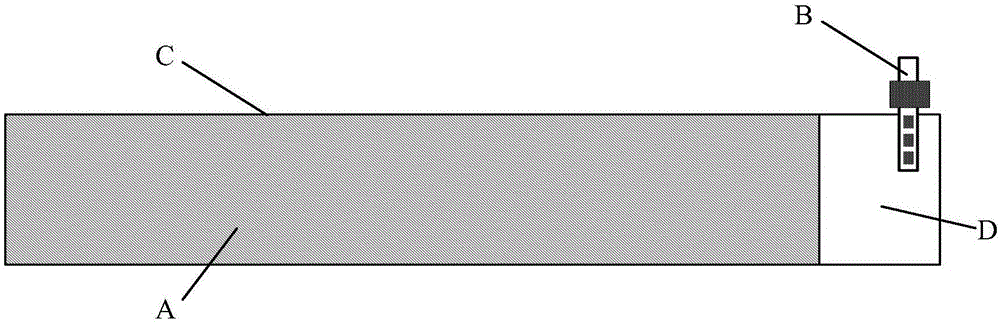

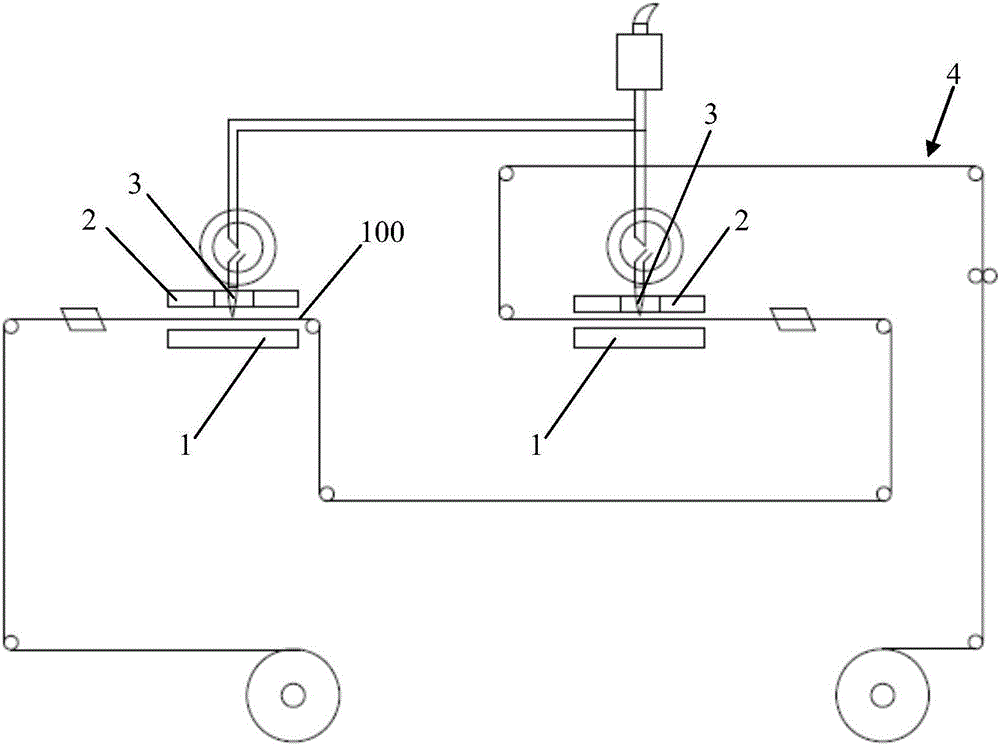

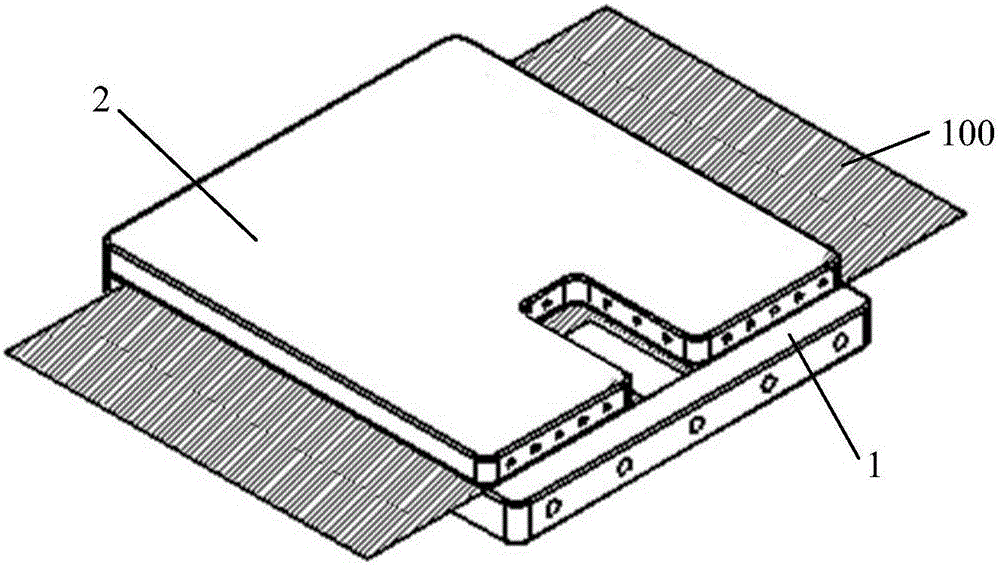

[0033] Such as figure 2 with image 3 As shown, the pole piece coating removal device of the present invention includes a cleaning platform 1, a pressing block 2, a laser head 3 and a pole piece conveying mechanism 4, the cleaning platform 1 is used to place the pole piece 100, and the pressing block 2 is arranged on the cleaning platform 1 , the pressing block 2 can flatten the pole piece 100 on the cleaning platform 1 , the laser head 3 is located above the cleaning platform 1 , and the pole piece 100 moves under the drive of the pole piece conveying mechanism 4 . The structures of the laser head and the pole piece conveying mechanism of the present invention are the same as those of the pole piece clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com