High-temperature molten salt pump

A high-temperature molten salt and molten salt technology, used in pumps, pump devices, pump components, etc., can solve the problems of sudden drop in axial temperature and axial stress deformation, and achieve the effect of reducing heat conduction and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

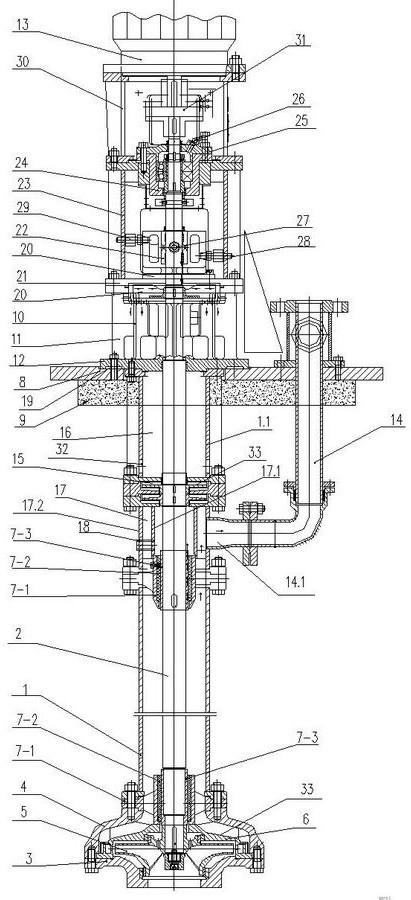

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

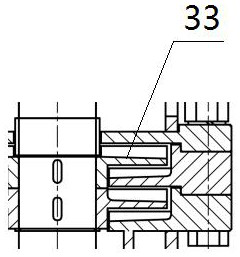

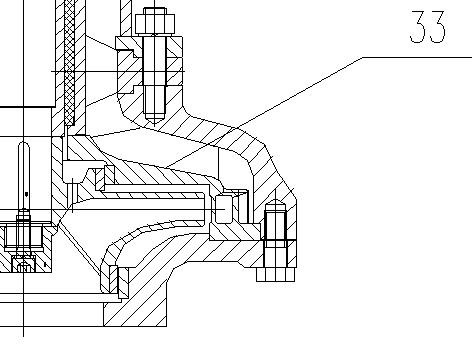

[0032] like figure 1 As shown in the high-temperature molten salt pump, a main shaft 2 is installed inside the pump from top to bottom, a suction cover 3 is provided at the bottom of the pump, a discharge body 4 is provided on the upper part of the suction cover 3, and an impeller 5 is provided at the center of the suction cover 3. The outer circle and upper end of the impeller 5 are provided with guide vanes 6, and the bottom end of the main shaft 2 passes through the centers of the impeller 5 and the guide vanes 6 in turn; the bottom end of the discharge body 4

[0033]It is connected with the suction cover 3 through bolts, the top of the discharge body 4 is connected with the cylindrical tube 1 through bolts, the outer circle of the guide vane 6 is connected with the inner stop of the suction cover 3 and the discharge body 4, and a sliding bearing body is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com