Passive residual heat removal heat exchanger testing device

A passive waste heat and test device technology, applied in cooling devices, nuclear power generation, climate sustainability, etc., can solve problems such as the inability to carry out horizontal section heat transfer test research, the accuracy and reliability of heat transfer test data, etc. Achieve the effect of shortening test preparation time, avoiding stress deformation, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

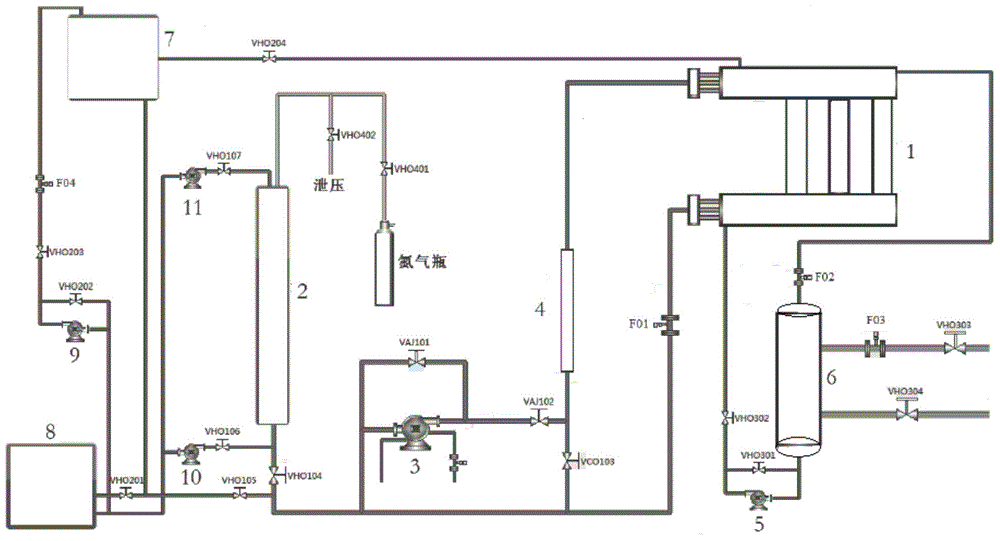

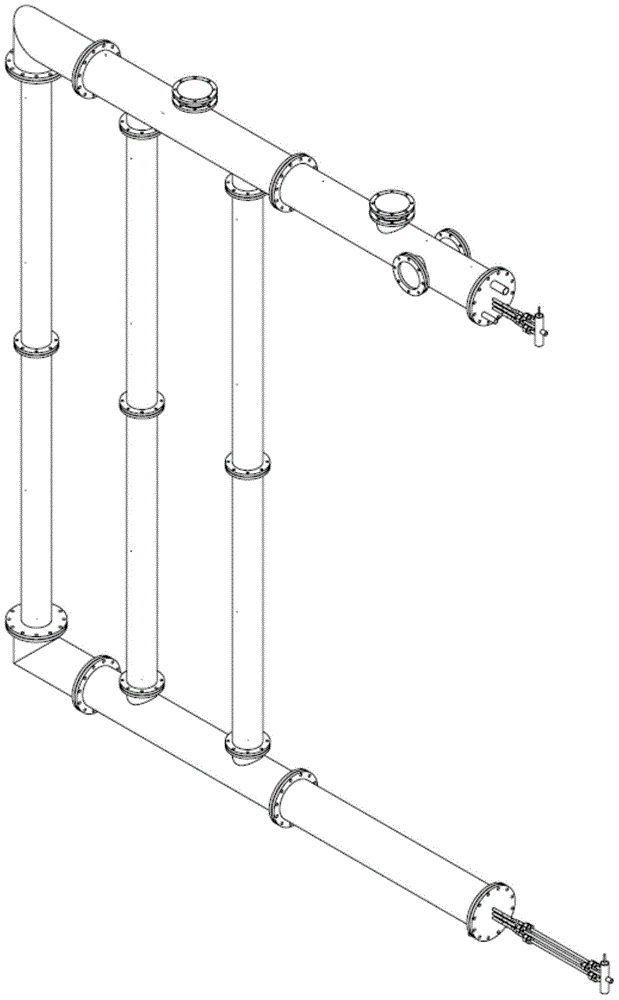

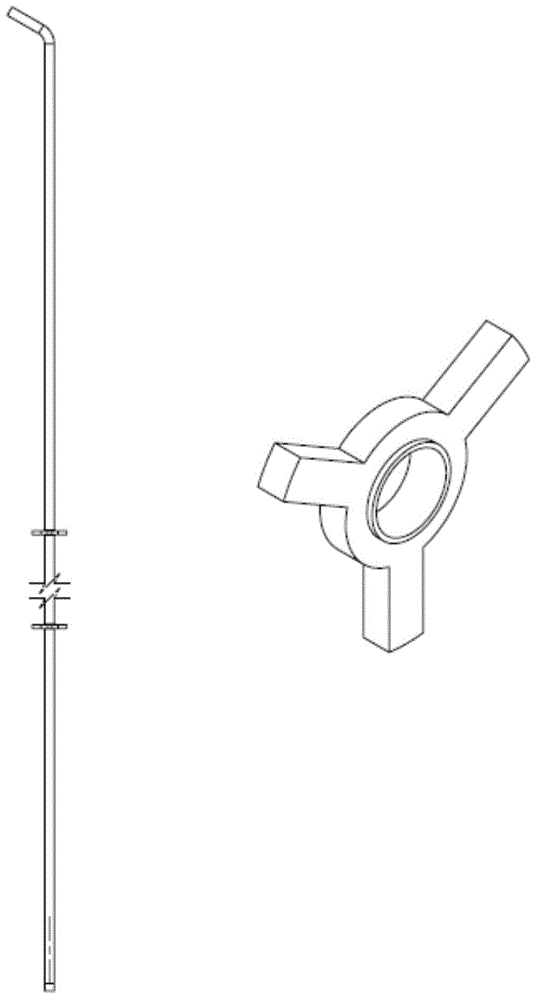

[0031] Such as figure 1 As shown, the passive waste heat removal heat exchanger test device includes heat transfer test section 1, voltage stabilizer 2, shielded pump 3, heater 4, circulation pump 5, heat exchanger 6, high-level water tank 7, low-level water tank 8, lift Pump 9, replenishment pump 10 and spray pump 11. Among them, the test section 1, the voltage stabilizer 2, the shielded pump 3, and the heater 4 constitute the main circuit system of the test device.

[0032] When the fluid flows through the heater 4 in the main circuit, the temperature rises and the density drops, so it flows upwards into the heat transfer test section 1 . In the heat transfer test section 1, the main circuit fluid is cooled and its density increases, so it flows downward, flows out of the test section, and returns to the heater 4 through the main circuit pipe. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com