Stereo standard device for multi-system coordinated measurement calibration

A standard, multi-system technology, applied in the field of geometric quantities, can solve the problems of large measurement workload, easy to fall apart under force, unification, etc., to achieve the effect of ensuring data stability, avoiding stress deformation, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

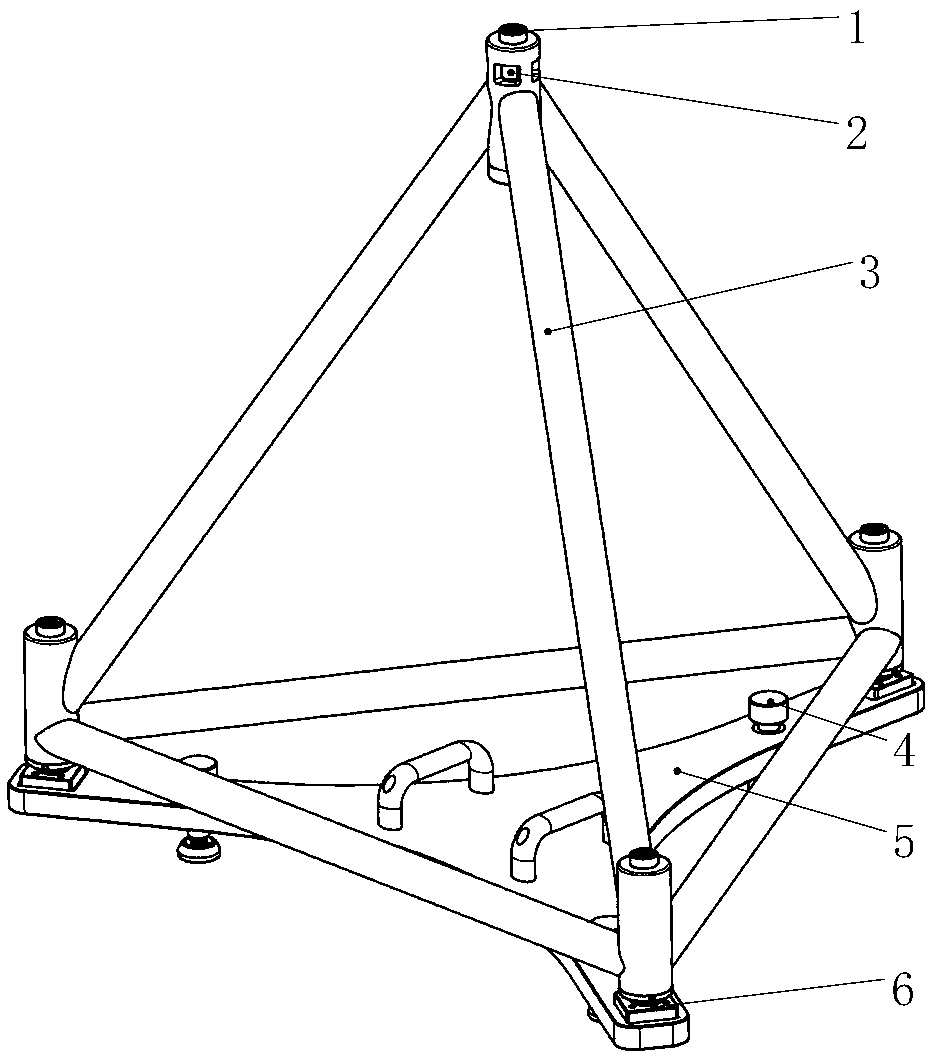

[0017] See attached figure 1 As shown, the main structure of the stereo standard for multi-system collaborative measurement and calibration of the present invention mainly includes a fixed frame 3 for installing a 1.5-inch target base 1 and a reference cube 2 for ensuring dimension stability, and a base 5 for installing and fixing frame 3. The fixing frame 3 is welded by eight invar steel pipes and four invar pin-hole seats. The 1.5-inch target seat 1 and the invar pin-hole seats are fitted with pin holes and fixed by screwing on the back. The reference cube mirror 2 is installed on the reference cube After the mirror mount is installed, it is screwed and fixed on the top Invar pin hole seat. The 1.5-inch target base 1 is equipped with a magnetic sheet, which can absorb a 1.5-inch spherical target to the contact surface of the target base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com