Winding forming die for small-opening composite material container

A composite material, winding molding technology, used in household appliances, other household appliances, household components, etc., can solve the problems of low dimensional accuracy of products, easy formation of air holes, large span of flap molds, etc., and achieve high dimensional accuracy and stability of molds. Good, repeatable assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

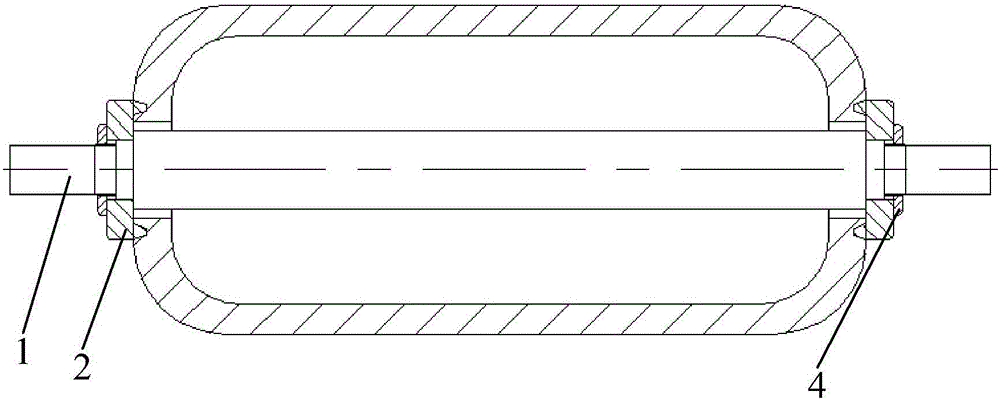

[0025] Take the small-mouth container winding mold with an inner diameter of 180mm, a length of 1200mm, and an opening of 125mm as an example. The mold assembly structure is shown in the attached figure 2 shown.

[0026] The outer diameter of the mandrel is φ100mm, the total length is 1600mm, and the preset positioning steps are φ75mm at two places 320mm from the reference positioning end and 130mm from the locking positioning end.

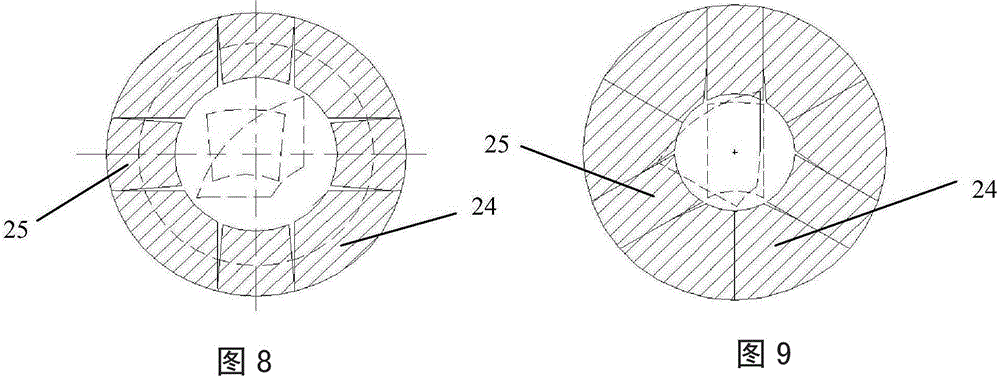

[0027] The total length of the valve mold is 1200mm, the combined outer diameter is φ180mm, and the thickness is 12mm. The support pile is located in the middle of the valve mold, and the length is 20mm. The width is 91.3mm, the narrow petal is a rectangular petal, the width is 46.4mm, the supporting pile structure of the petal mold is as attached Figure 5 As shown, the split structure is as shown in Figure 8. The inner side of the base positioning end of the valve mold is symmetrically processed with φ111mm as the center, and the circular tra...

Embodiment 2

[0034] Take the small mouth container winding molding mold with an inner diameter of φ161mm, a length of 533mm, an opening of the reference positioning end of φ58mm, and an opening of the locking positioning end of φ110mm as an example. The mold assembly structure is as follows Figure 7 shown.

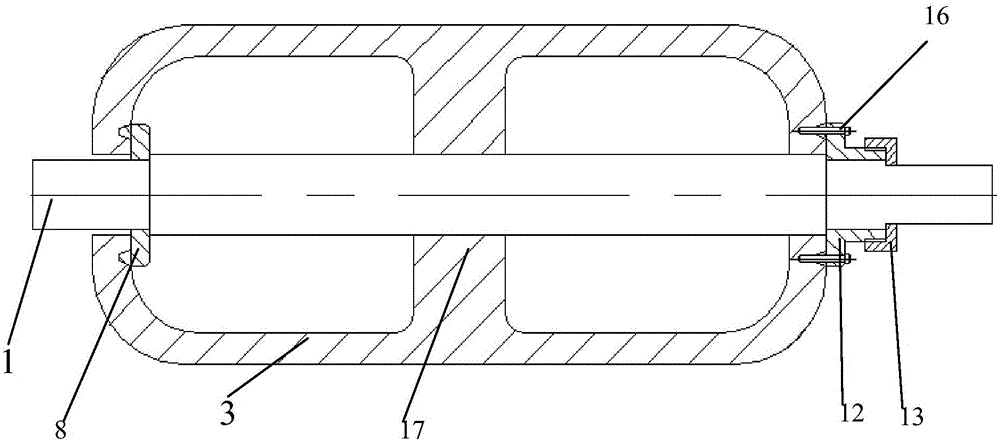

[0035] The outer diameter of the mandrel is φ69mm, and the total length is 925mm. The preset positioning steps are φ63mm at 225mm from the reference positioning end and 248.5mm from the locking positioning end, and the length is 20mm. 230mm respectively prefabricated φ60mm metal parts installation positioning step 22, the length is 20mm; at 130mm from the reference positioning end and 221mm from the locking positioning end, respectively preset M56×2 installation metal parts thread 23, the length is 20mm .

[0036]The total length of the valve mold is 463mm, the combined outer diameter is φ161mm, and the thickness is 8mm. One support pile is set in the middle position, and the length ...

Embodiment 3

[0043] Take the small-mouth container winding molding mold with an inner diameter of φ225mm, a length of 1500mm, and openings of both the reference positioning end and the locking positioning end of φ98.5mm as an example. The mold assembly structure is shown in the attached Figure 4 shown.

[0044] The outer diameter of the mandrel is φ53mm, and the total length is 1826.8mm. The preset positioning steps are φ48.3mm at two places 192.5mm away from the reference positioning end and 192.5mm away from the locking positioning end, and the length is 13.8mm. The positioning end 178.6mm prefabricated the metal parts installation positioning step φ43.3mm, the length is 24.7; the M40×2 thread of the metal parts is pre-installed at the two positions 153.9mm from the reference positioning end and the locking positioning end, the length Both are 20mm.

[0045] The total length of the valve mold is 1362.3mm, the combined outer diameter is φ225mm, and the thickness is 20.9mm. There are 2 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com