Method for producing a toothbrush, and toothbrush

a technology for which is applied in the field of producing a toothbrush and a mouthpiece, can solve the problems of compromising the appearance of the mouthpiece, affecting the quality of the mouthpiece, etc., and achieves a high degree of automisation in manufacture and few method steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

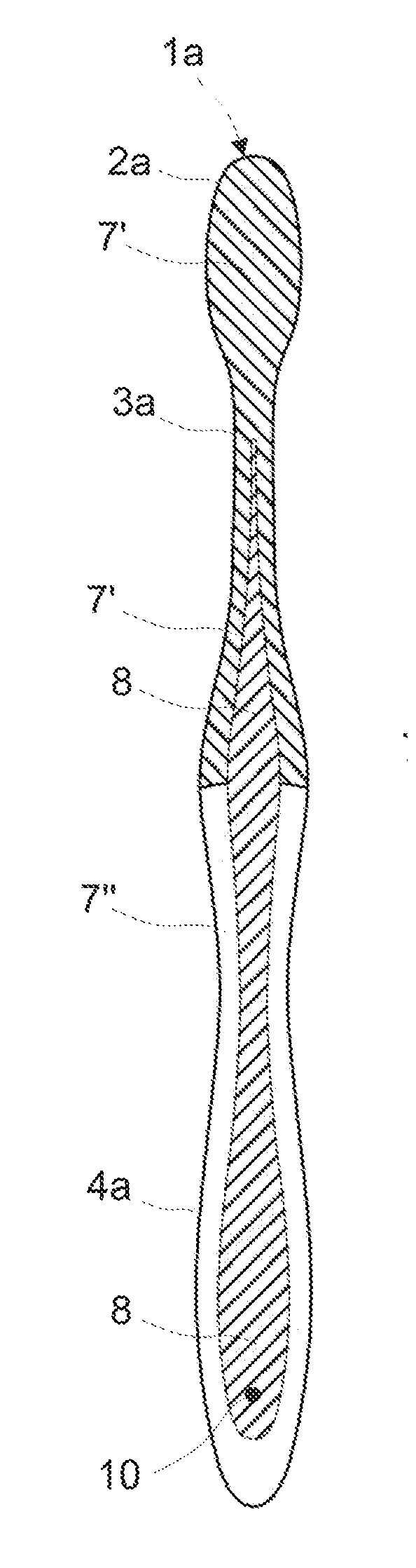

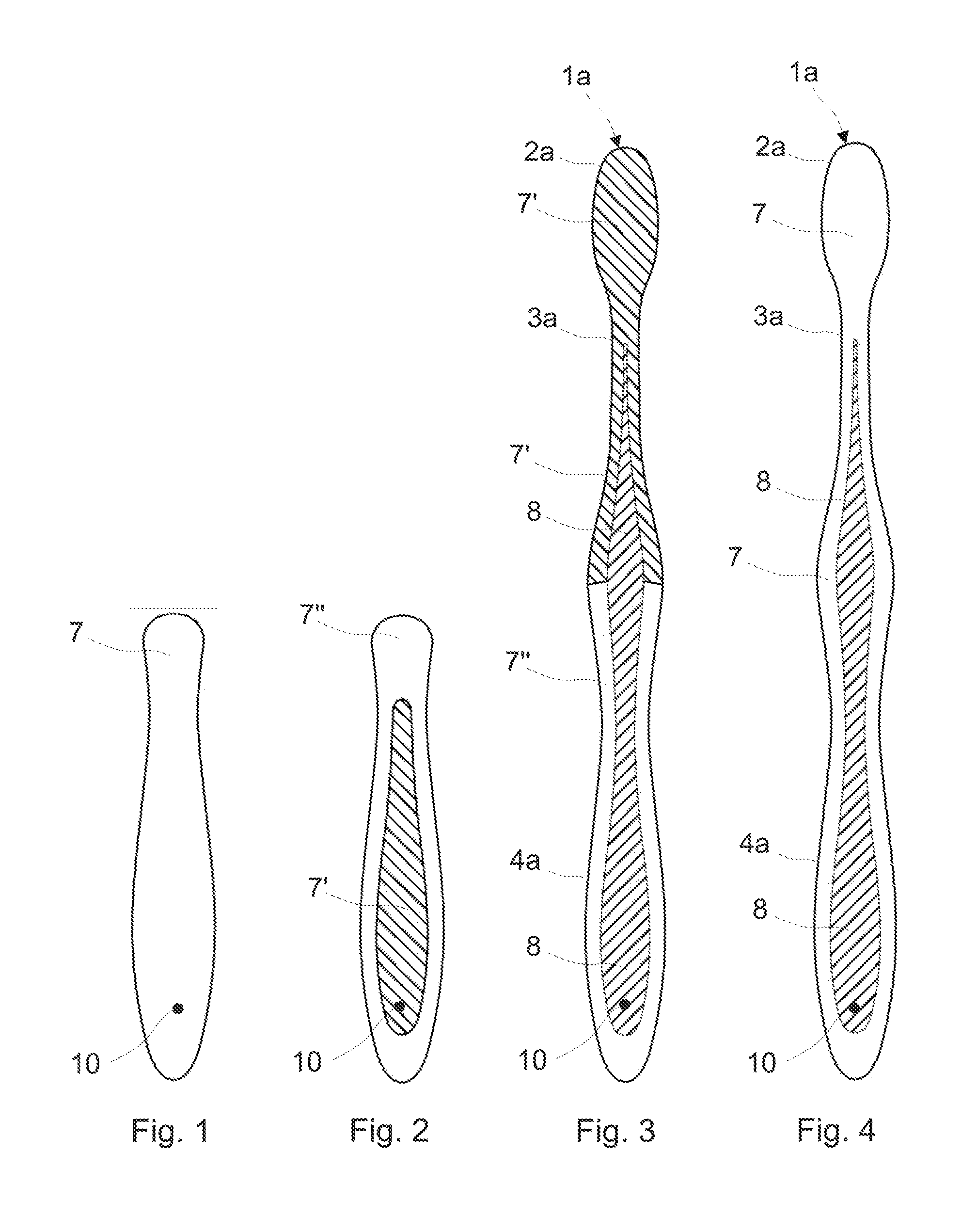

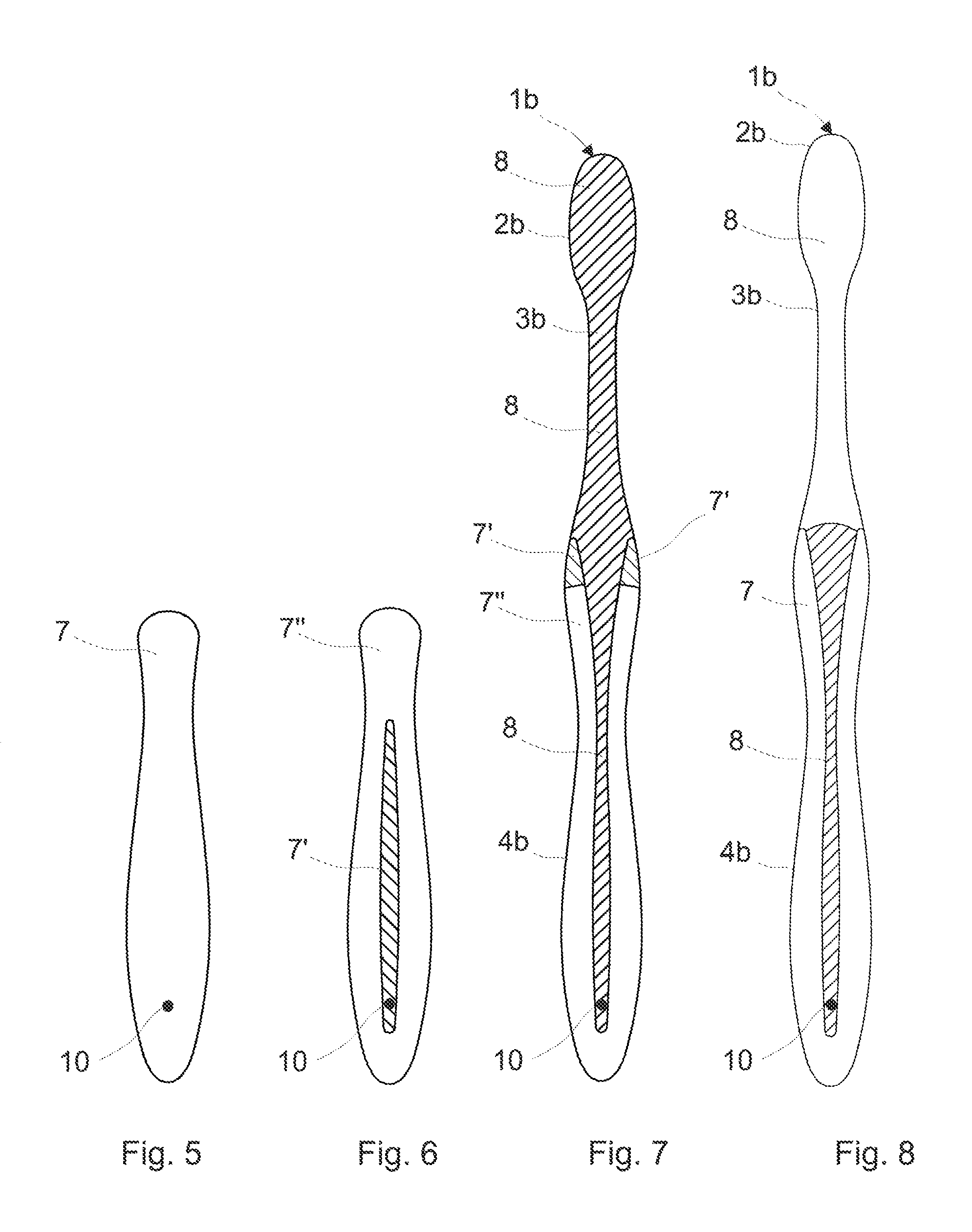

[0139]FIGS. 1 to 4, in a purely schematic manner, show the manufacture of a grip body 1a according to a first design variant. For manufacturing the shown grip body 1 in the first design variant, a first material component 7 is injected into a tool cavity (not shown) in a first step. The tool cavity or the grip body to be manufactured 1a is a longitudinal component and comprises a grip part 4a, a neck part 3a and a head part 2a. The injection point 10 is arranged in the grip part 4a. The tool cavity in a first step is only partly filled with the first material component 7, wherein at least the grip part of the tool cavity is completely or at least partly filled with the first material component due to the arrangement of the injection point 10 in the grip part 4a. The injected first material component 7 thereby assumes the contour of the tool cavity in the grip part 4a (see FIG. 1). FIG. 1 schematically shows the outline contour of the body moulded in the first injection procedure wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com