Tool and cutting insert for the fine turning of grooves in workpieces

A technology of cutting inserts and tools, applied in the direction of tools, cutting inserts, manufacturing tools, etc. for lathes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

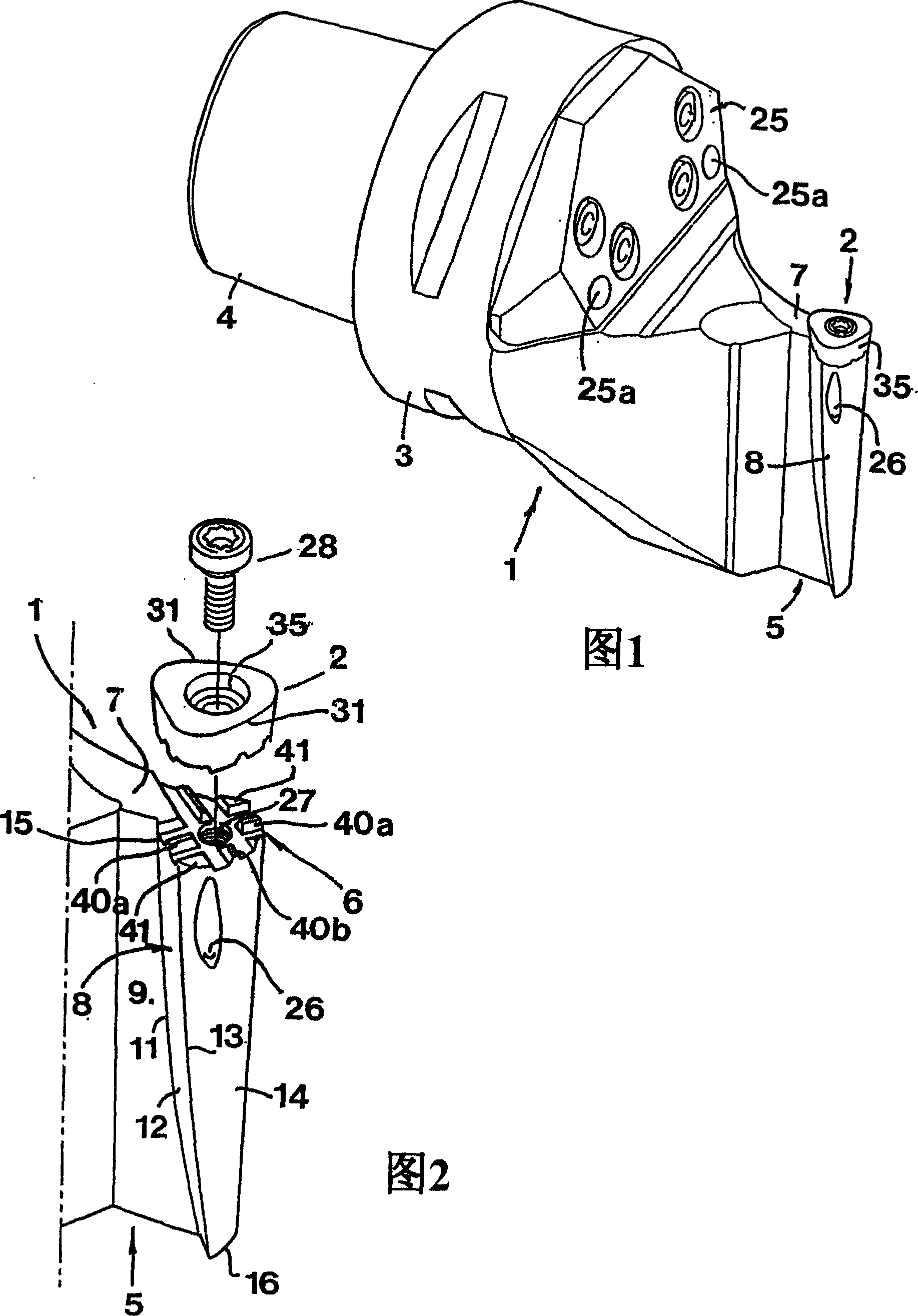

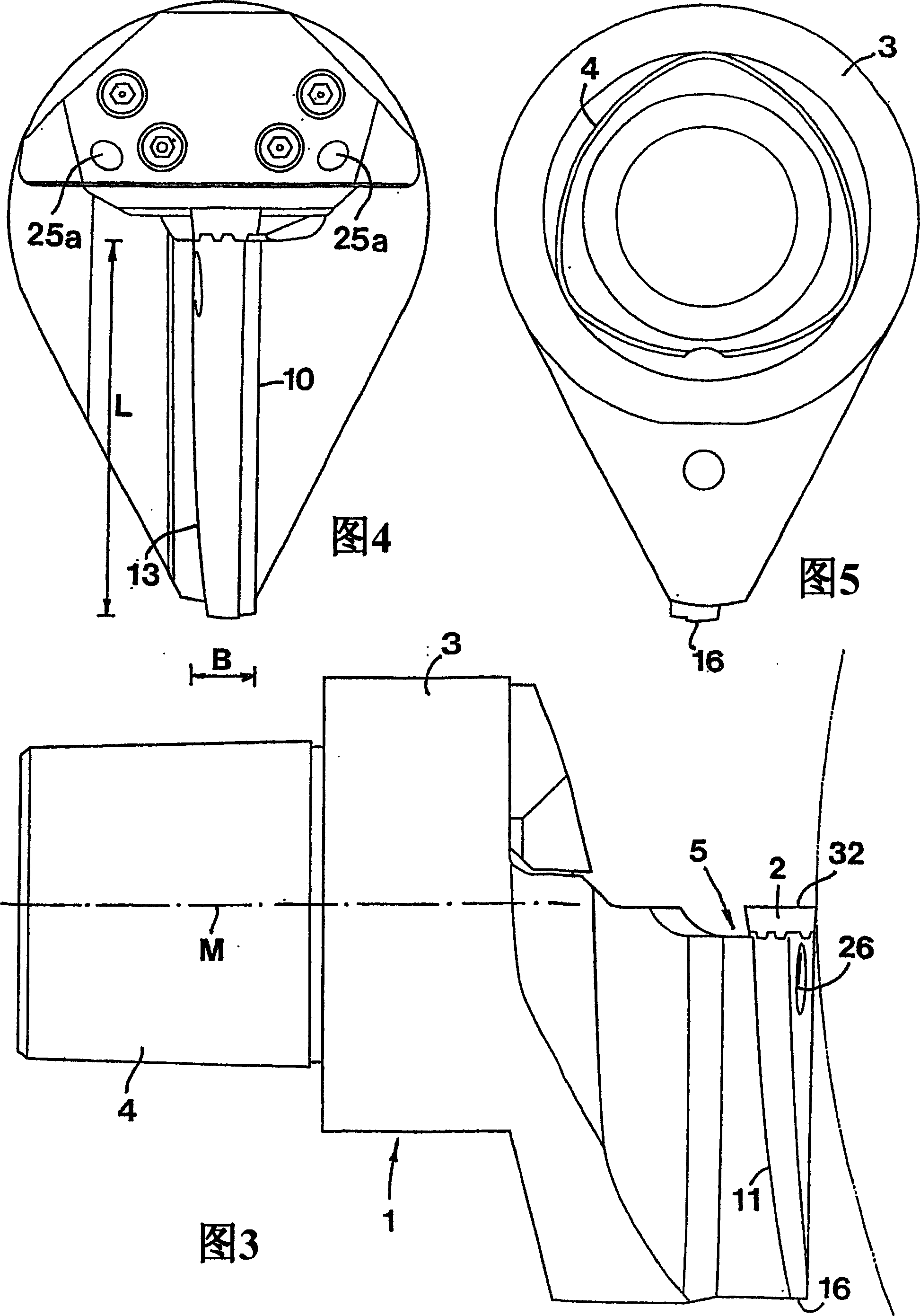

[0023] In Figures 1 and 2, a tool in the form of a turning tool is shown, comprising a base body 1 and a cutting insert 2 detachably mounted on the base body. In this example, the base body 1 has a cylindrical main part 3, from its rear side extending a connecting element 4 capable of being fixed in a machine tool (not shown). On the front, the basic body has a carrier, indicated overall at 5 , which has a seat 6 in which the cutting insert 2 can be fastened. The bracket has a narrow neck 7 and a support 8 protruding laterally from the neck.

[0024] The cutting insert 2 will be further described in detail below with reference to FIGS. 7-10 .

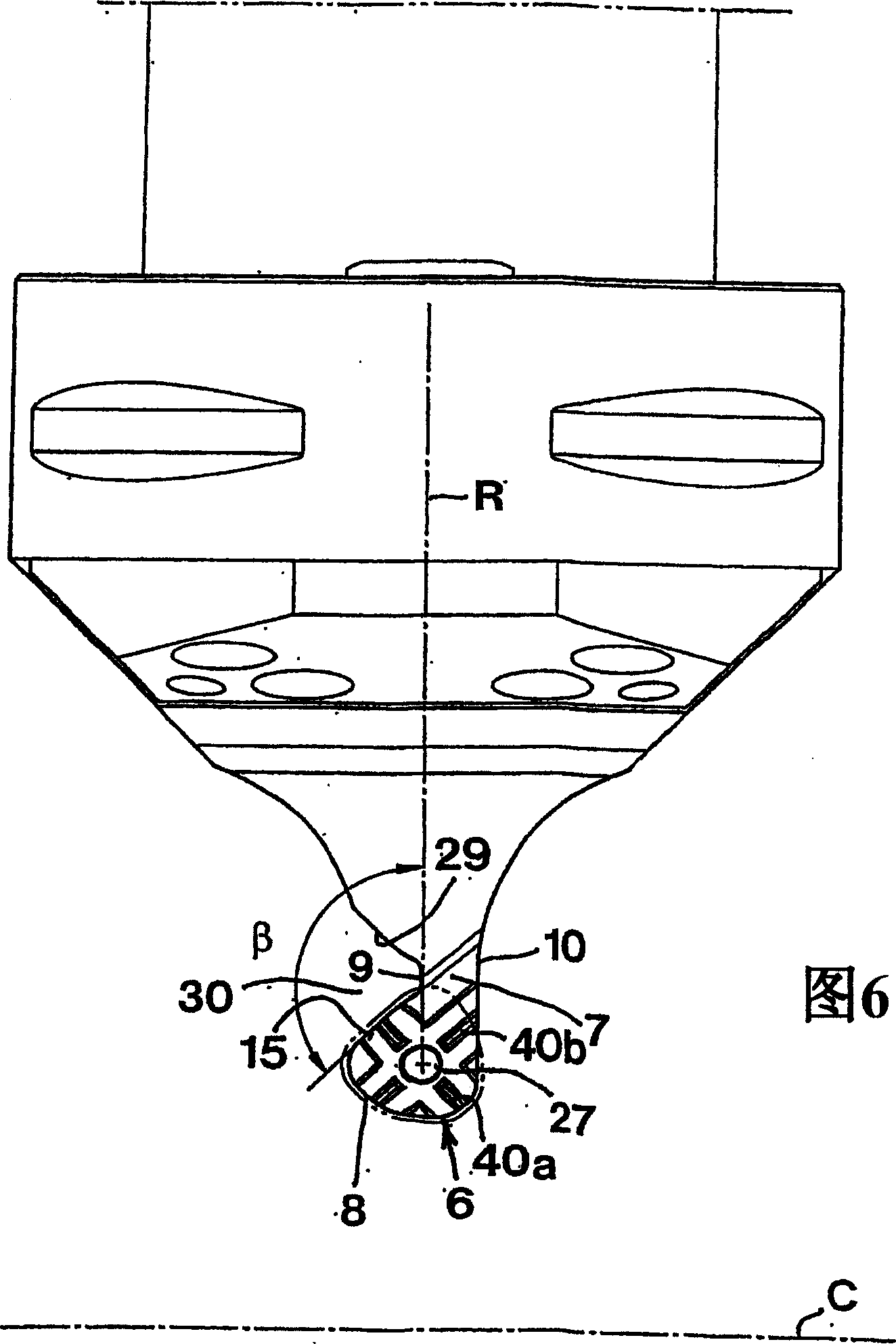

[0025] Reference is now also made to FIGS. 3-6 , which together with FIGS. 1 and 2 illustrate in detail the design for the bracket 5 . In Fig. 6 it is shown how the relatively thin neck 7 is bounded by two flat, opposing side surfaces 9, 10, which are preferably parallel to each other. The support part 8 only protrudes from one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com