Device for measuring parameters at submersible electric pump outlet

A submersible electric pump and parameter measurement technology, applied in the direction of measuring devices, pump control, non-variable pumps, etc., can solve problems affecting measurement accuracy, capillary steel tube wear, capillary steel tube blockage, etc., to eliminate the risk of blockage, Improving accuracy and avoiding leakage issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with each accompanying drawing, the present invention is described in detail.

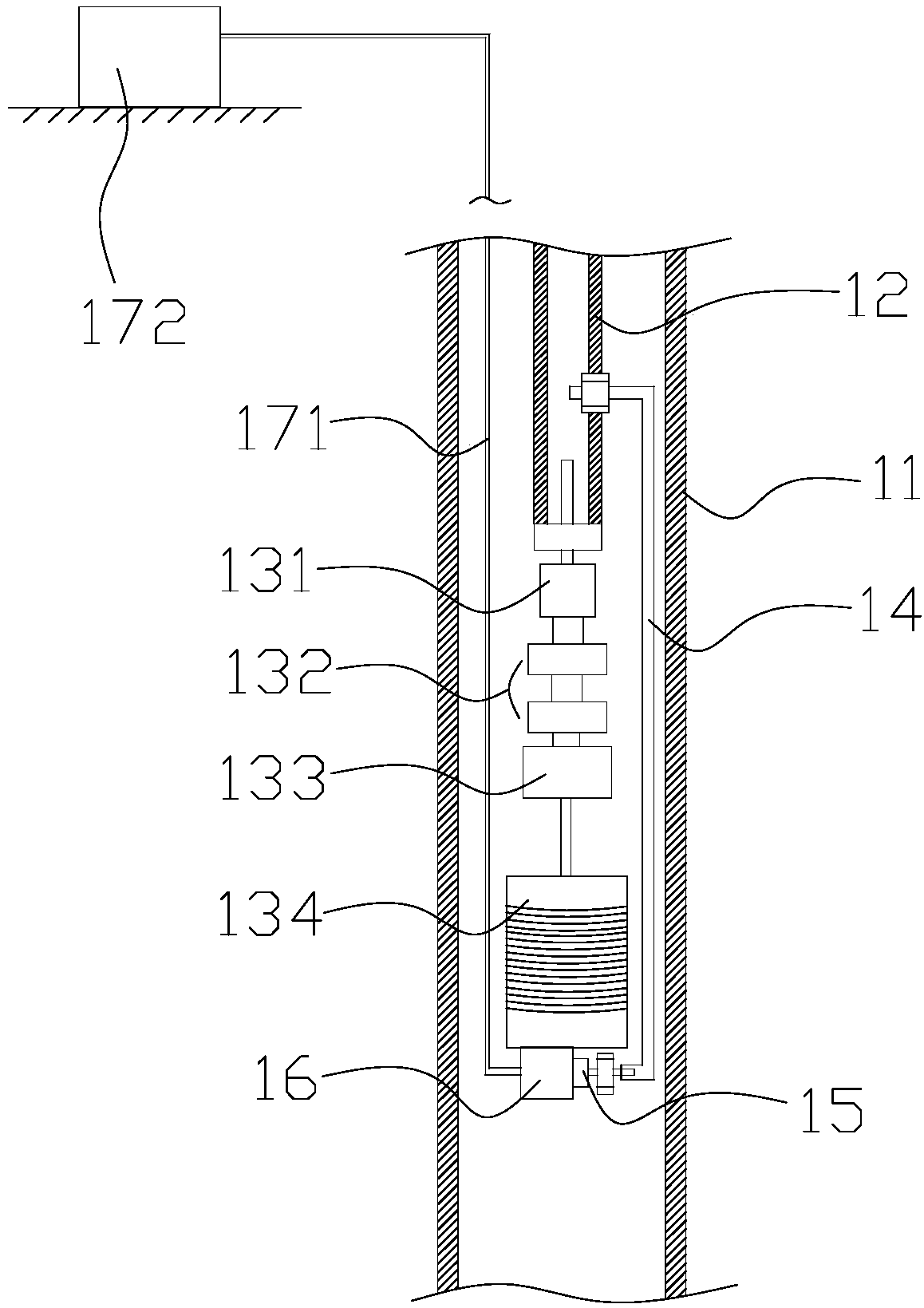

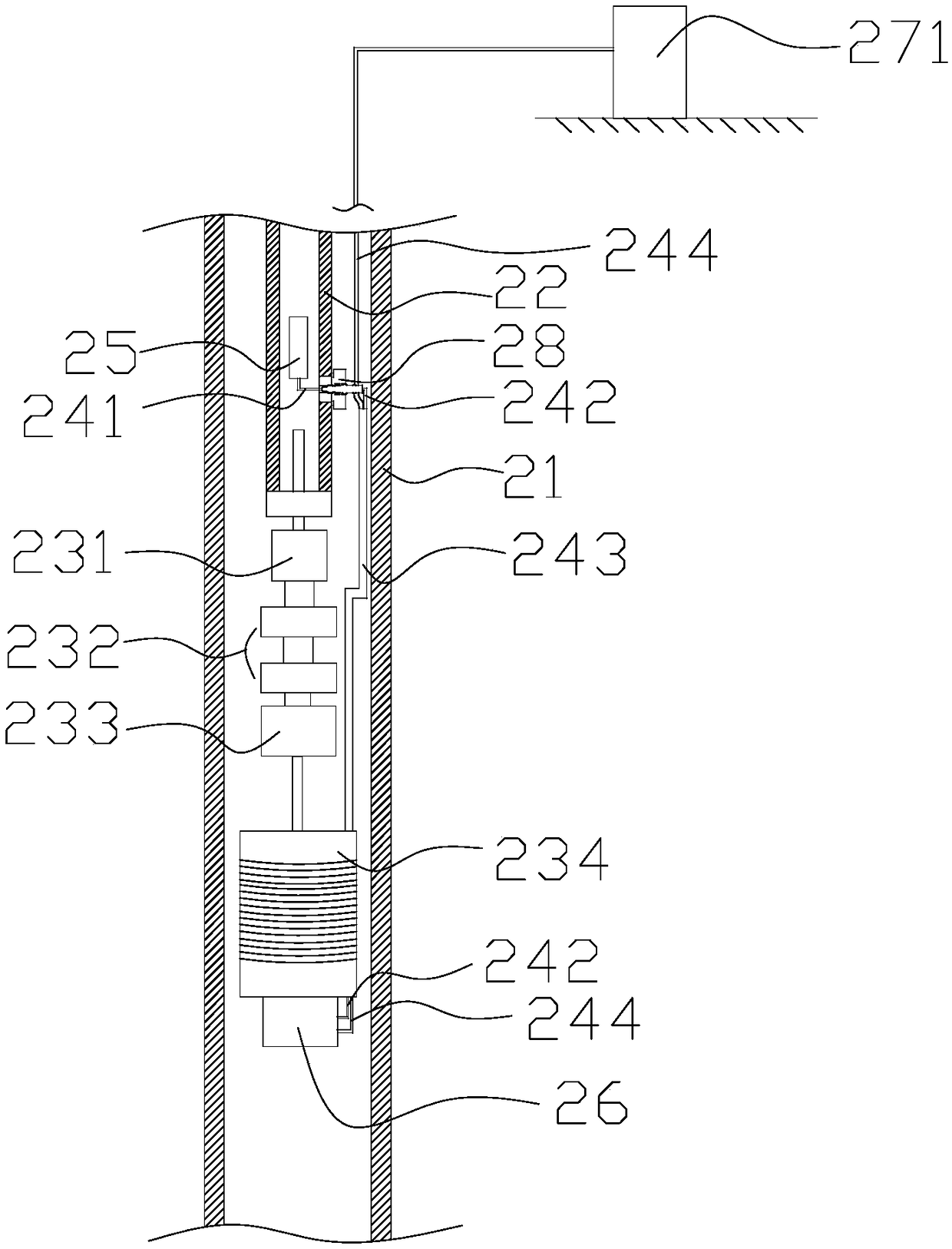

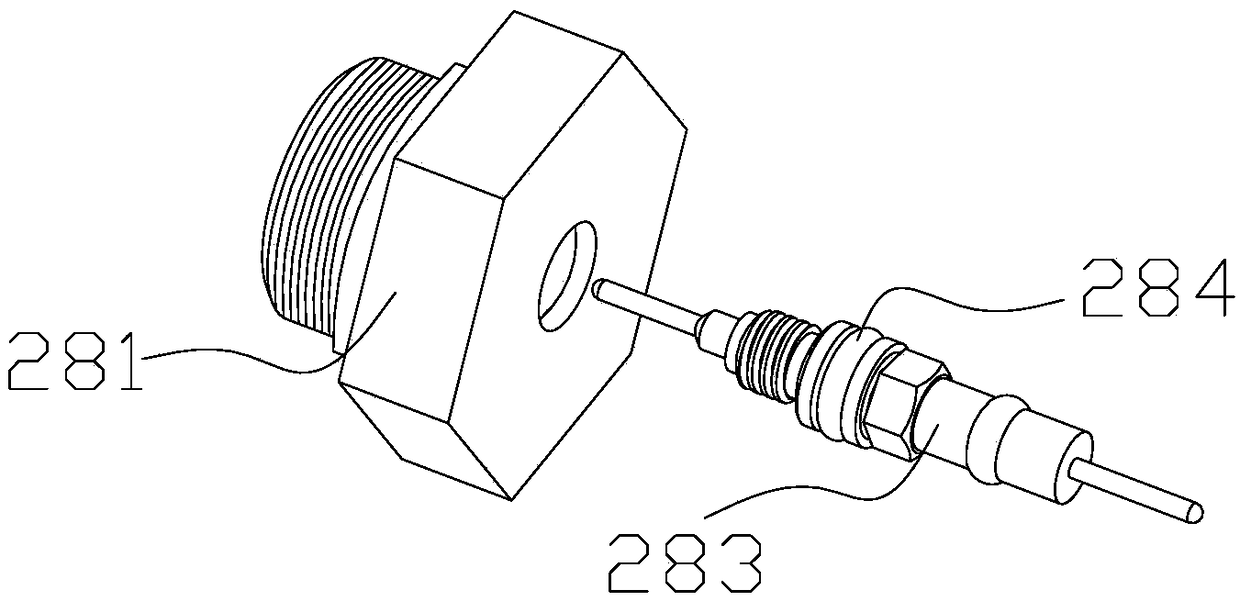

[0027] Such as figure 1 Shown is the sectional view of the device measuring the parameters at the outlet of the electric submersible pump 131 in the prior art, wherein a small hole is drilled on the oil pipe 12, and a capillary with an outer diameter of 3.175mm (commonly used minimum outer diameter) The steel pipe 14 is inserted in the oil pipe 12, and a signal receiving module 16 is installed at the lower end of the submersible motor 134, and the other end of the capillary steel pipe 14 is connected to the pressure sensor 15, and the pressure sensor 15 is directly connected to the signal receiving module 16, and the signal receiving module 16 It is connected with the signal processing display device 172 on the ground through a power cable 171 . The disadvantages of the above structure are: (1) due to the small annular gap between the submersible motor 134 and the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com