Annular flow local dynamic liquid film average thickness direct measurement method

A measurement method and average thickness technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement devices, etc., can solve problems such as poor real-time performance, complex structure of the measurement system, and inability to quickly respond to liquid film changes, and achieve the effect of solving winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

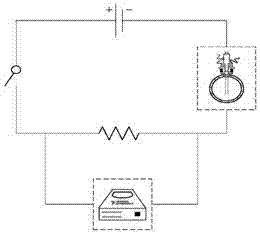

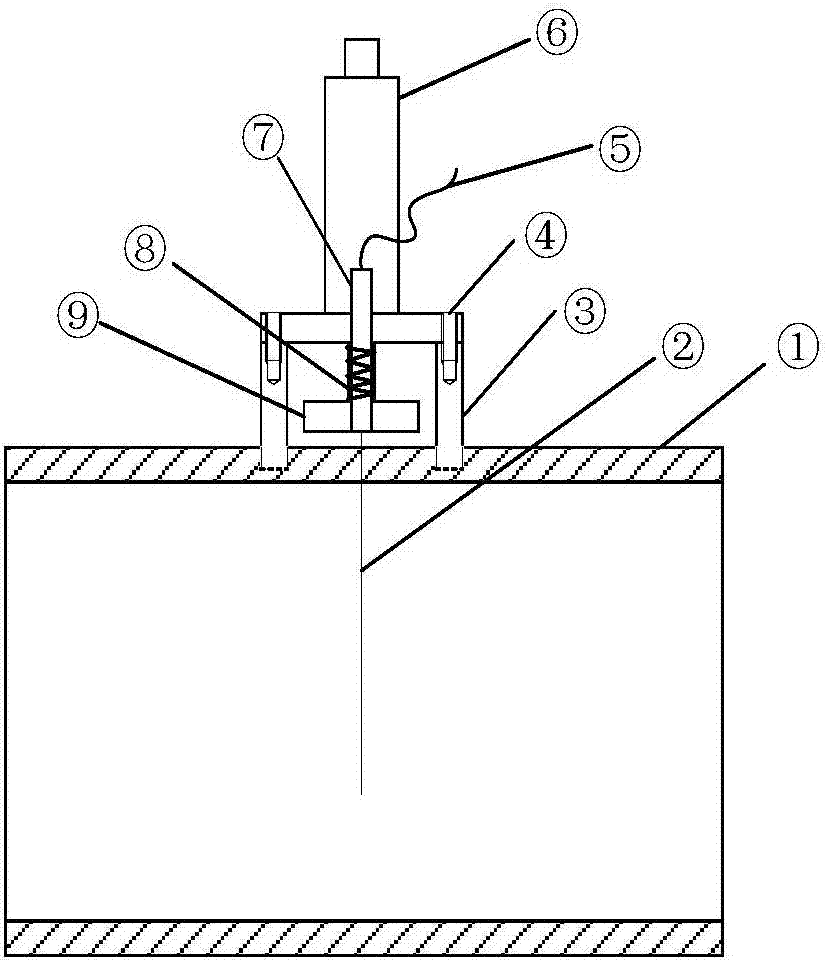

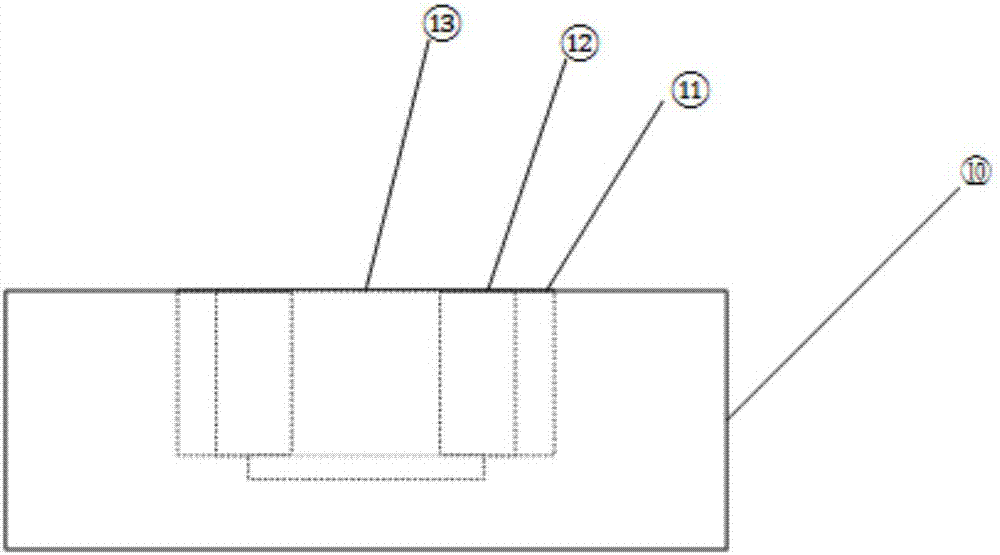

[0020] The system includes data measurement module, data acquisition module and data processing module. Among them, the data measurement module includes a DC power supply, a contact probe sensor with adjustable insertion depth, and a precision resistor; the data acquisition module includes a data acquisition card, a computer and data acquisition software; the data processing module includes a computer and implements a weighted average thickness algorithm software. The device provides a stabilized voltage source through a DC stabilized power supply module, which is connected in series with a precision resistor and a contact probe sensor with adjustable insertion depth. The data acquisition module is used to collect the voltage at both ends of the precision resistor. When the conductive liquid submerges the probe probe, The two probes are connected, and the entire circuit forms a loop. The current flows through the precision resistor, and the voltage at both ends is not zero. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com