Device and method for testing fastening pressure of shape memory alloy pipe joint

A technology of memory alloy and testing method, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as low reliability, high operating cost, and poor practicability, and achieve convenient operation and testing device Small and compact, solve the effect that cannot be directly measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

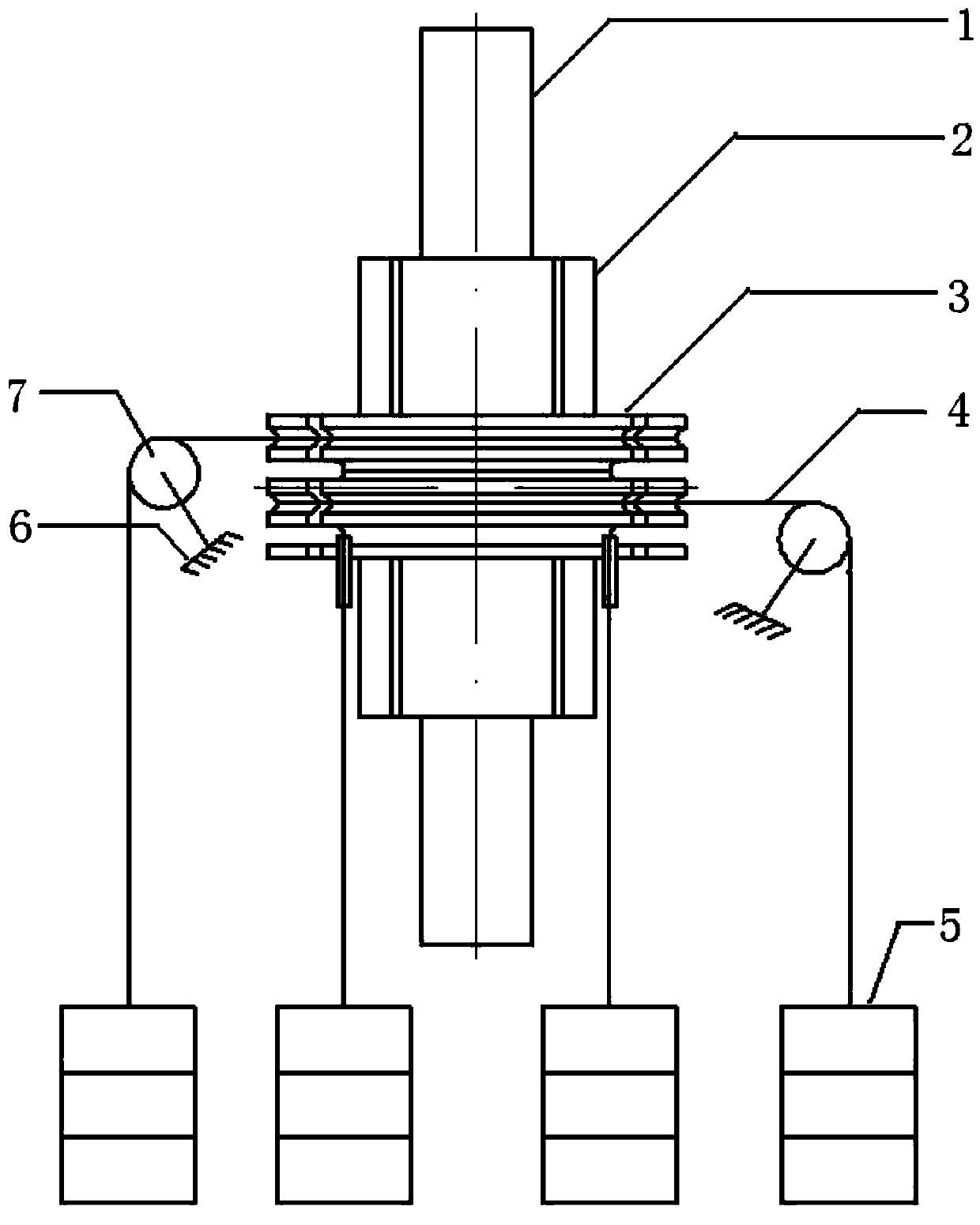

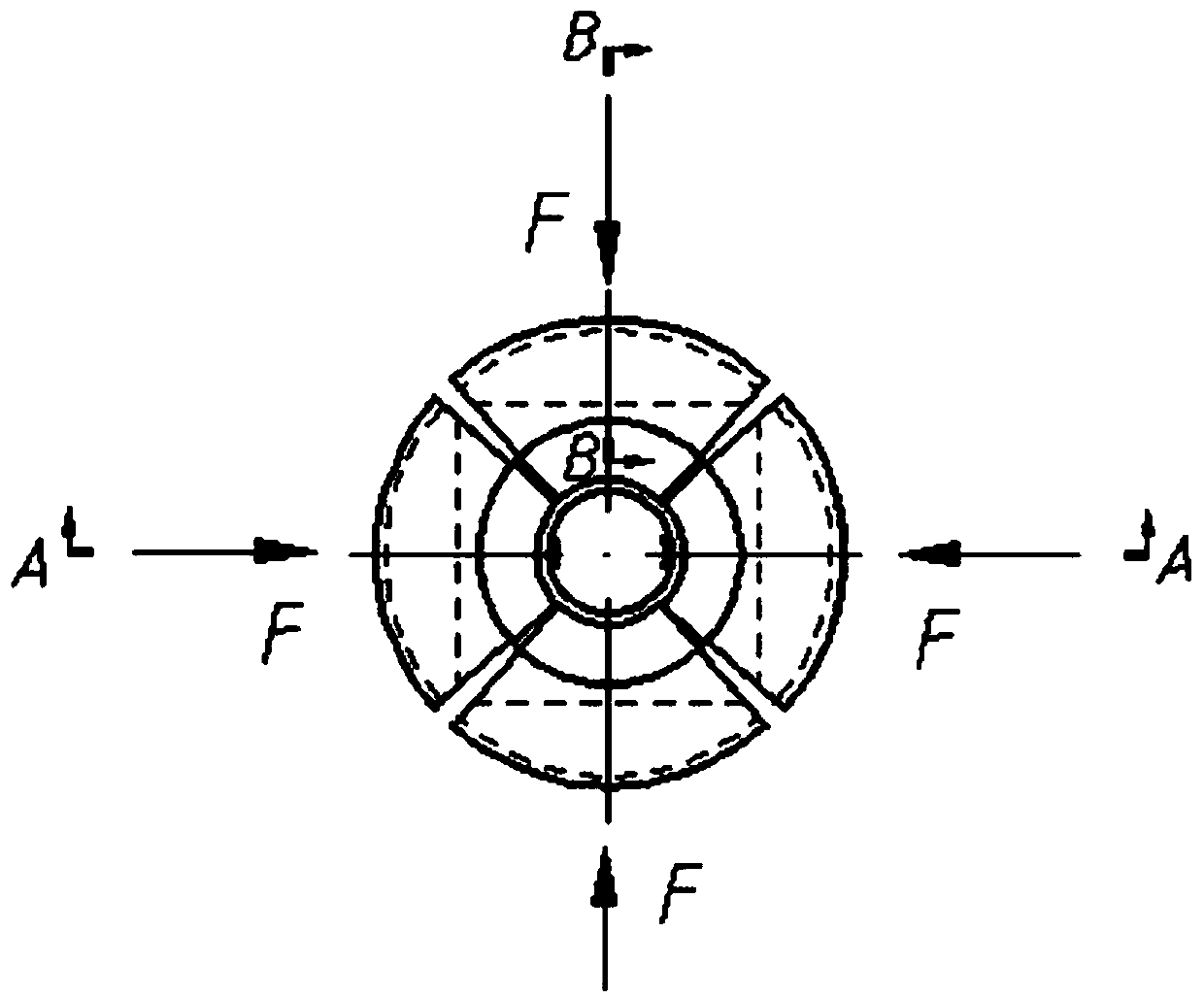

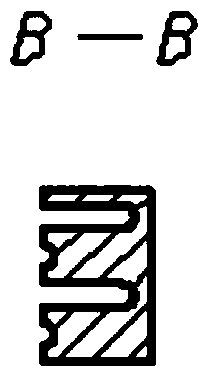

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the establishment of the calibration relationship of the fastening pressure involved in the present invention is realized in this way, which includes a connected pipe 1, an arc-shaped steel sheet 2, a loading block 3, a steel wire rope 4, a loading weight 5, a support frame 6, and a pulley 7 and strain gauges8. The inner wall of the connected pipe 1 is symmetrically pasted with strain gauges 8; the four arc-shaped steel sheets 2 are evenly attached to the outer periphery of the connected pipe 1 at the same height, and there is an equidistant gap between adjacent arc-shaped steel sheets 2; the curved steel sheets The outer periphery of 2 is welded with a loading block 3, which is used to convert the loaded weight into a force on the arc-shaped steel sheet, thereby realizing a series of known pressures on the outer surface of the pipe to be taken over; each loading block 3 is provided with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com