Machine tool spindle intelligent online monitoring and integration diagnosis system based on Internet

A technology of machine tool spindle and comprehensive diagnosis, applied in general control system, control/regulation system, computer control, etc., can solve the problems of tool interruption, long consultation period of experts, poor real-time performance, etc., and achieve the effect of shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

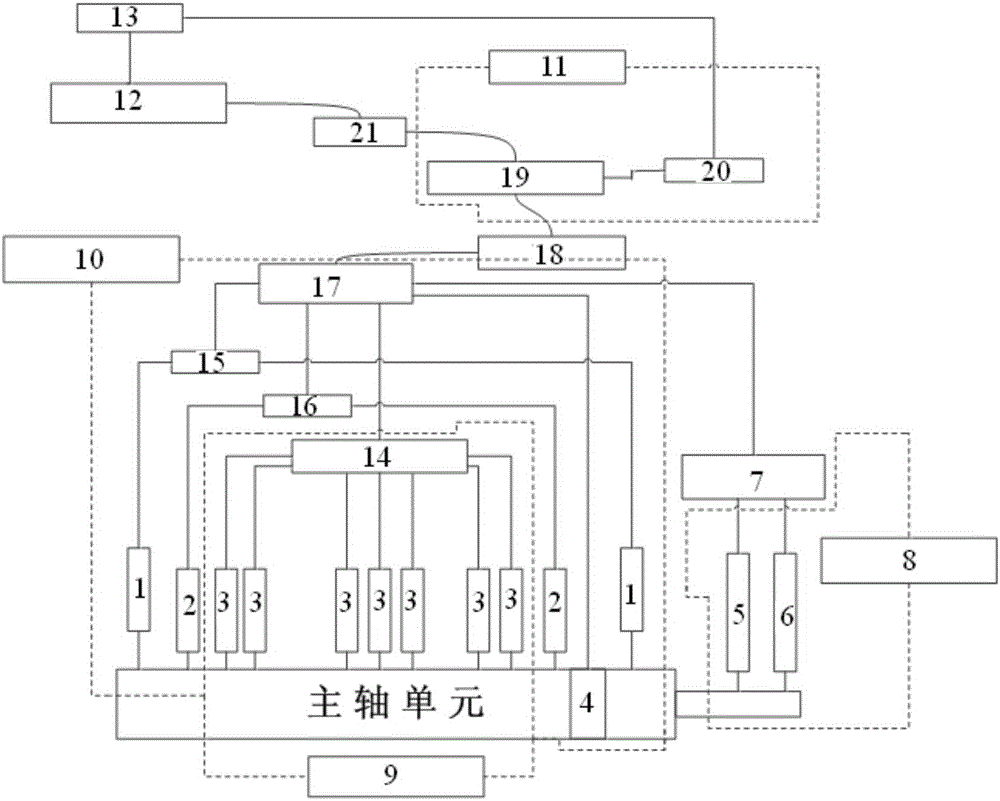

[0026] refer to figure 1 , the Internet-based intelligent online monitoring and comprehensive diagnosis system for machine tool spindles described in the present invention includes a vibration comprehensive evaluation system 10, a temperature comprehensive evaluation system 9, a data acquisition card 17, a cutter working state comprehensive evaluation system 8, and a machine on-site working state monitoring system 11 and a remote fault diagnosis system; the comprehensive vibration evaluation system 10 includes a displacement sensor 1 for detecting the vibration displacement information of the main shaft, an acceleration sensor 2 for detecting the acceleration information of the main shaft, and a magnetic sensor for detecting the vibration phase information of the main shaft. Grid encoder 4, the output end of displacement sensor 1 is connected with data acquisition card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com