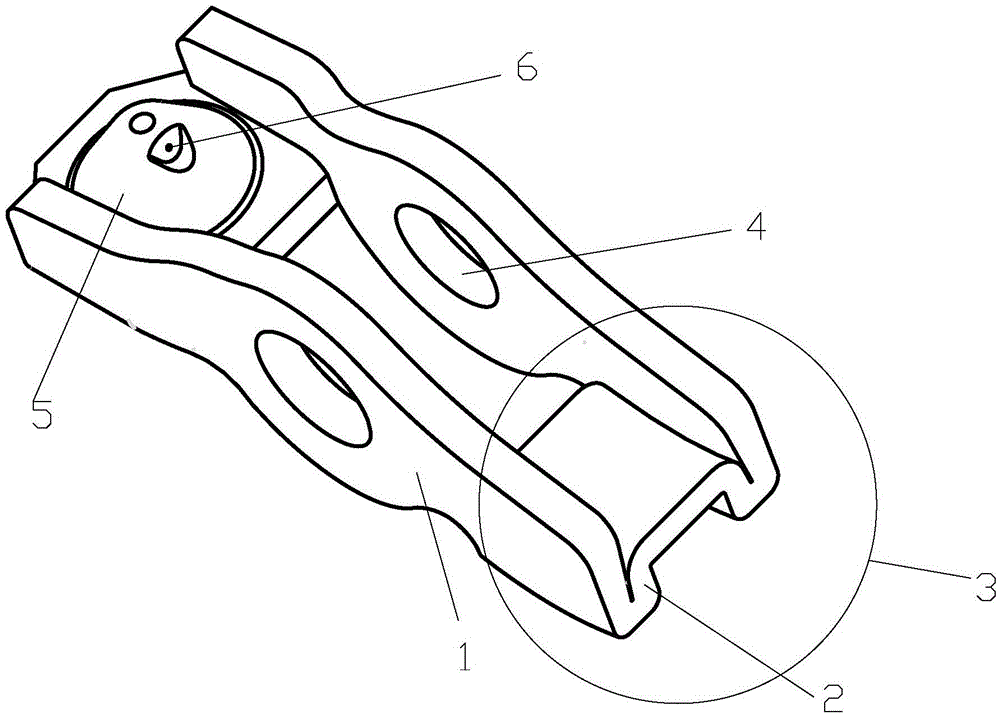

A method for processing and forming a rocker arm bracket

A technology of processing molding and rocker arm frame, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of curved crown side wall forming and thinning, etc., and achieve low mold force, high production efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

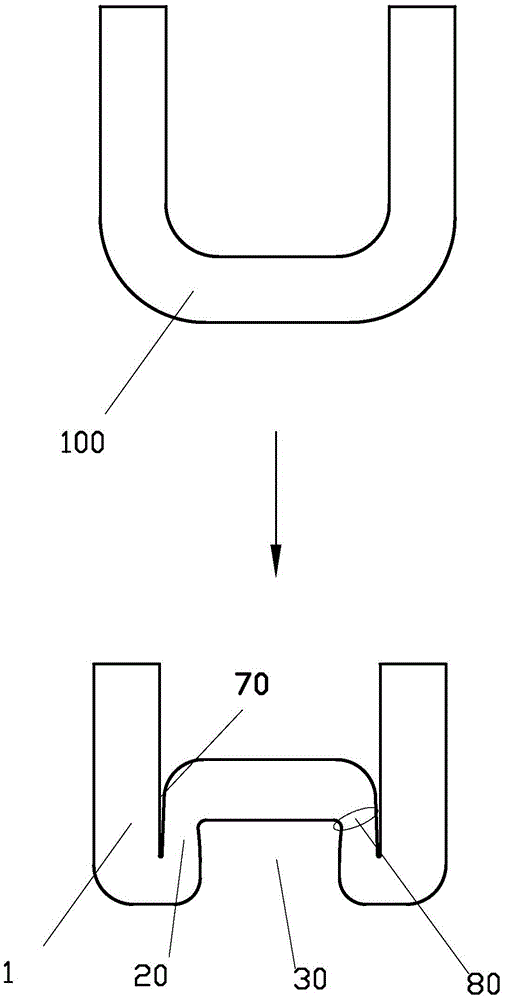

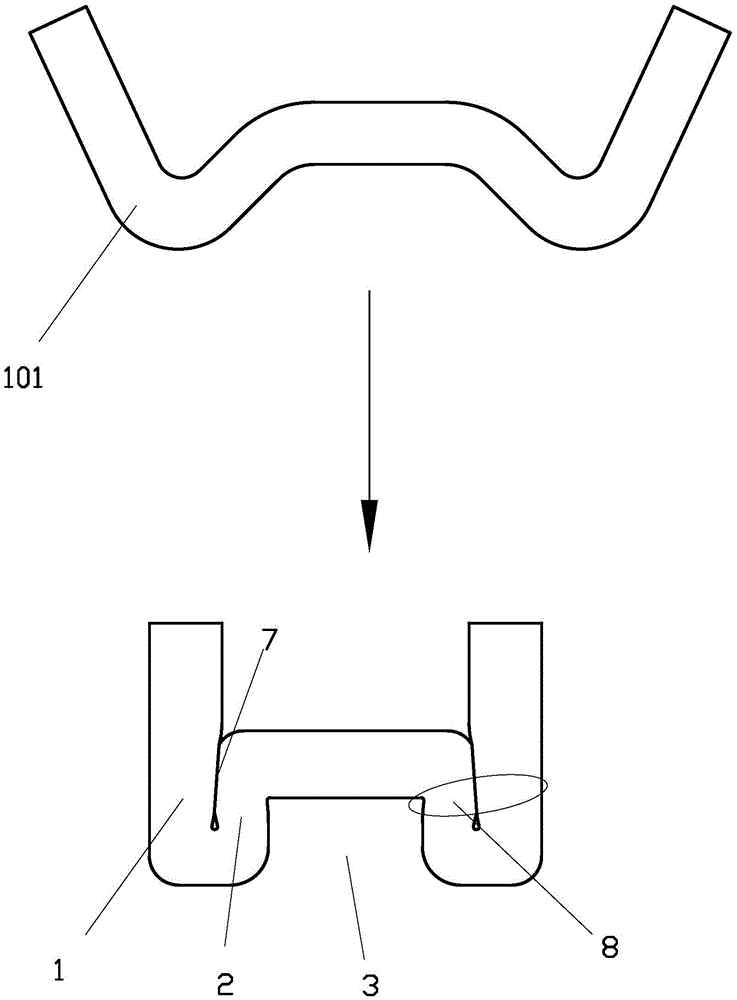

[0041] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings: the rocker arm frame adopts a process of continuous forming of steel strips on a progressive die, and the main steps include: punching and guiding positive pin holes, punching out the shape of the rocker arm frame, and pre-folding "W" shape, side extrusion into "H" shape, one-time simultaneous extrusion of ball socket and curved crown arc surface, side punching pin shaft hole, blanking, etc. Such as figure 2 As shown, in the traditional molding process, the curved crown is first bent into a U-shaped workpiece 100, then the upper mold presses the side wall 1, and the lower mold presses upwards to form an "H" shape. Due to the limitation of the size L, When the side wall 20 and the curved crown 30 are pressed upward, the junction 80 of the side wall 20 and the curved crown 30 will have a serious local stretching and thinning phenomenon, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com