Direct-driven fully automatic impeller type washing machine and washing method thereof

A technology of a pulsator washing machine and a washing method, which is applied to other washing machines, washing machines with containers, control devices of washing machines, etc. The effect of improving the clarity and washing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

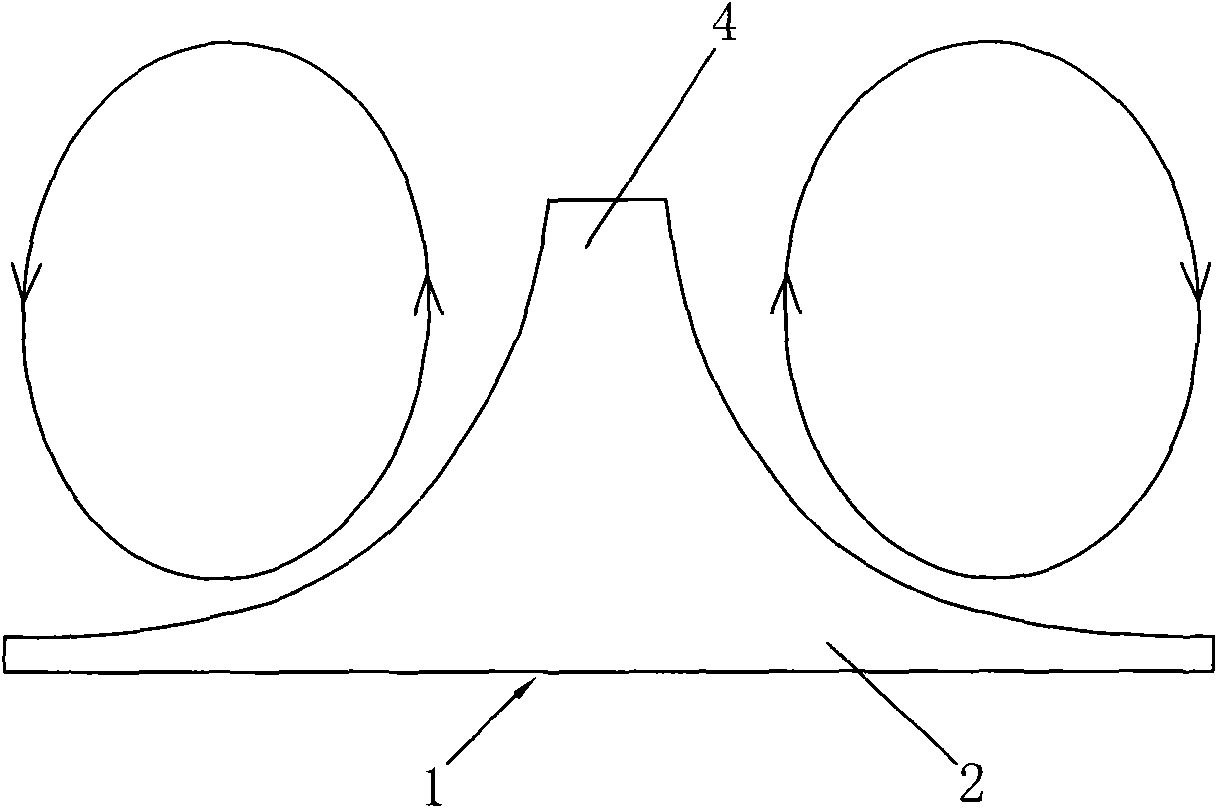

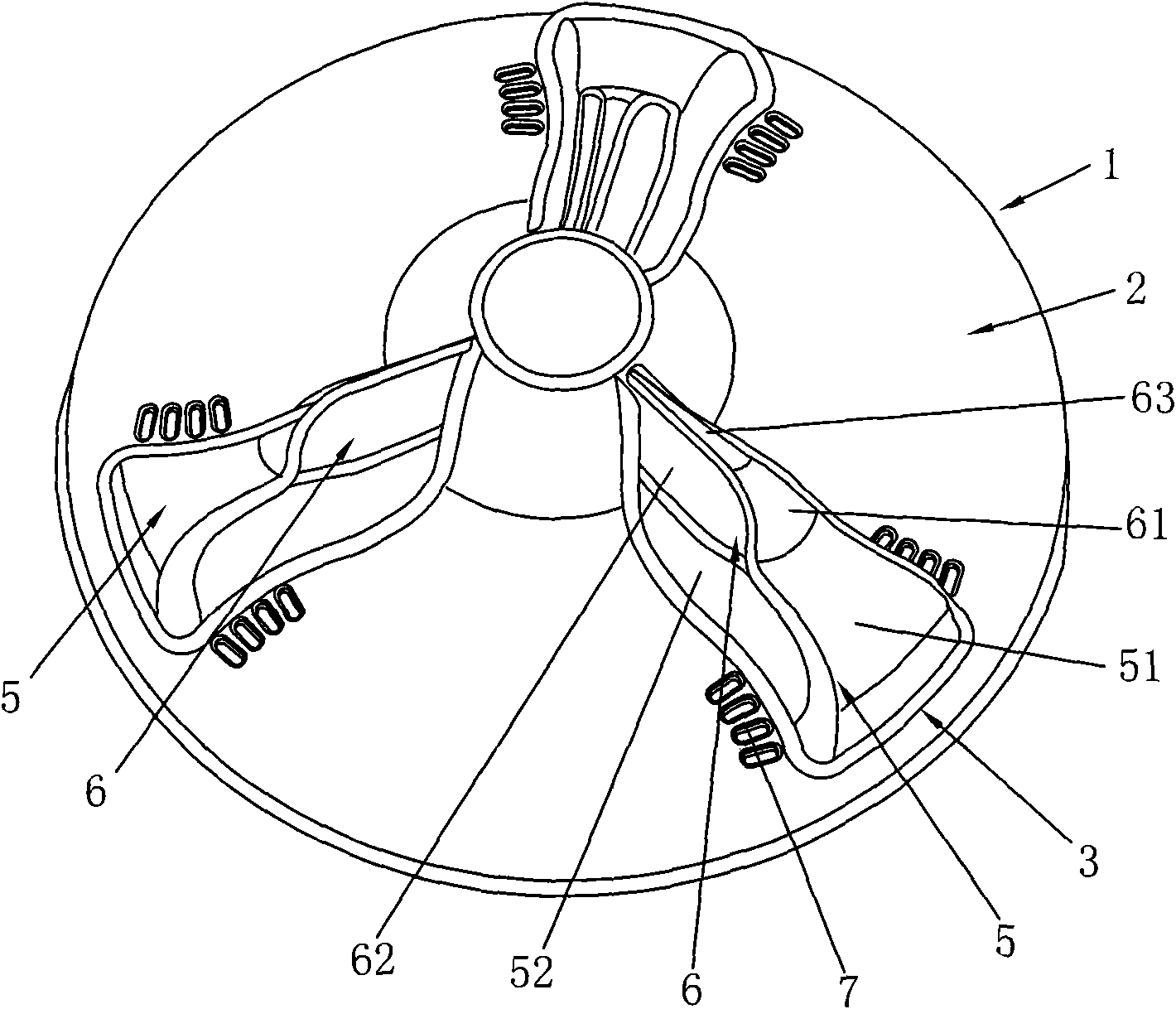

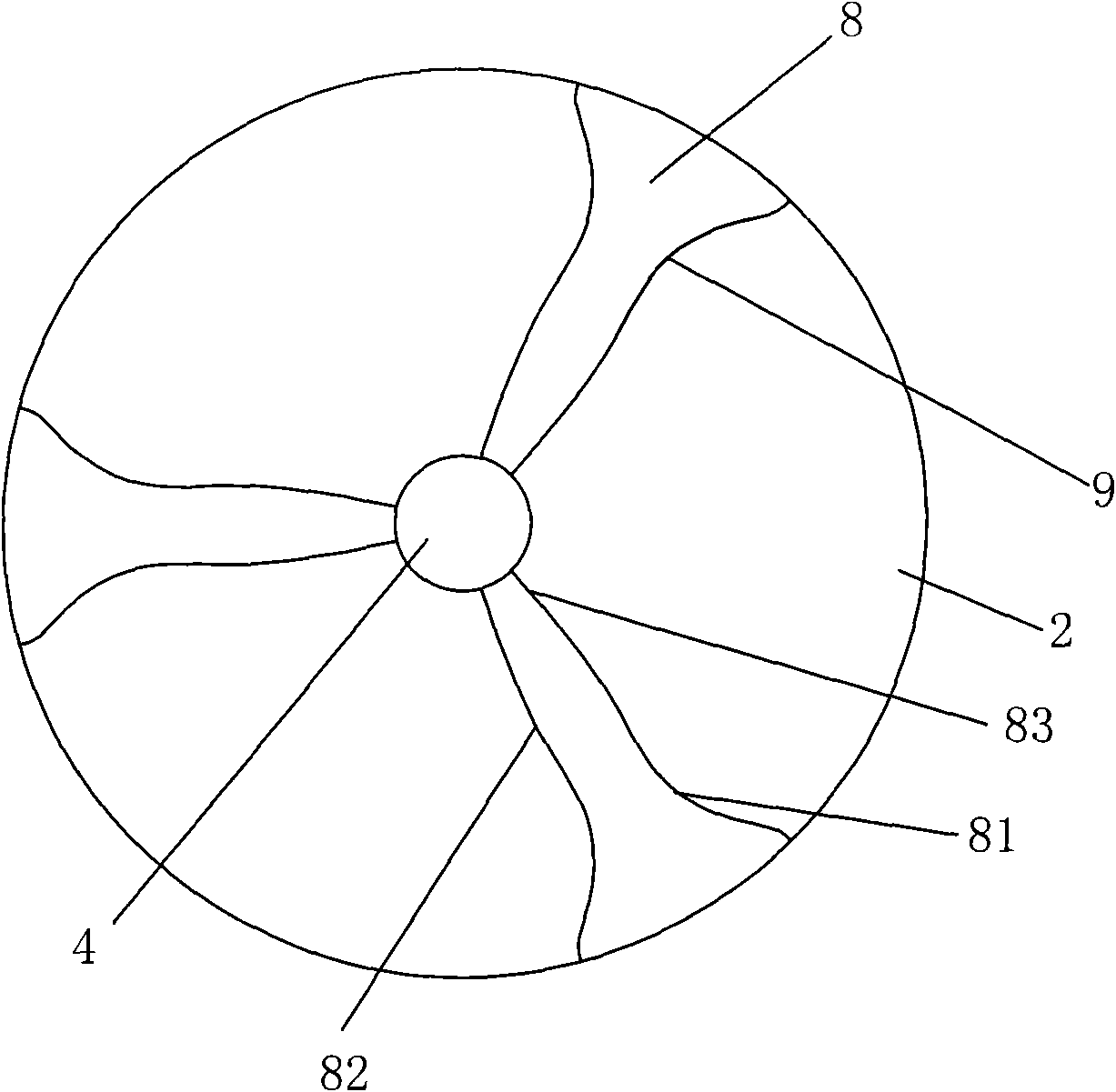

[0047] Such as Figure 10 As shown, the pulsator 1 used in the present invention is directly driven by the motor 100, and does not change speed through a reducer. When washing, the initial speed of the starting process is lower than the maintaining speed of the running process. The variable-speed circulating water flow drive mode corresponds to the water circulation in the washing tub. The motor first runs for a long time to drive the strong water flow to turn the clothes over, and then performs a short-term balanced water flow drive to automatically correct the bias of the clothes in the washing tub. , and cycle in turn. The driving mode of the present invention can make the laundry flip up and down in the water for washing, and utilizes the combination of the non-stop friction and stirring force of the laundry and the impact force of the water during the frequent forward and reverse rotation of the direct drive pulsator. , forming a special washing method that can exert app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com