Container cap

a technology for container caps and seals, applied in the field of container caps, can solve the problems of undetected solidification of adjuncts, and achieve the effect of superior sealing ability and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the attached drawings.

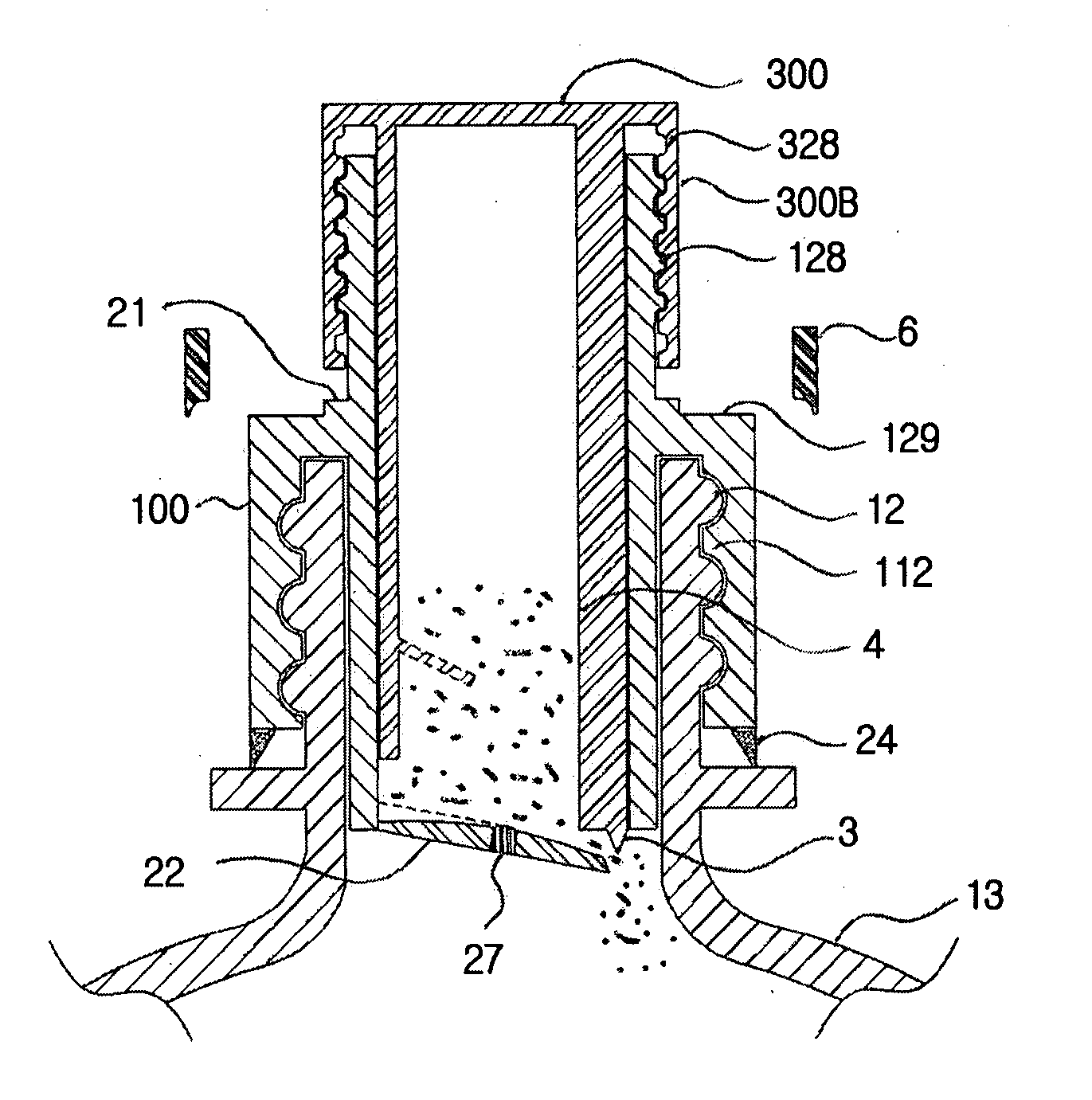

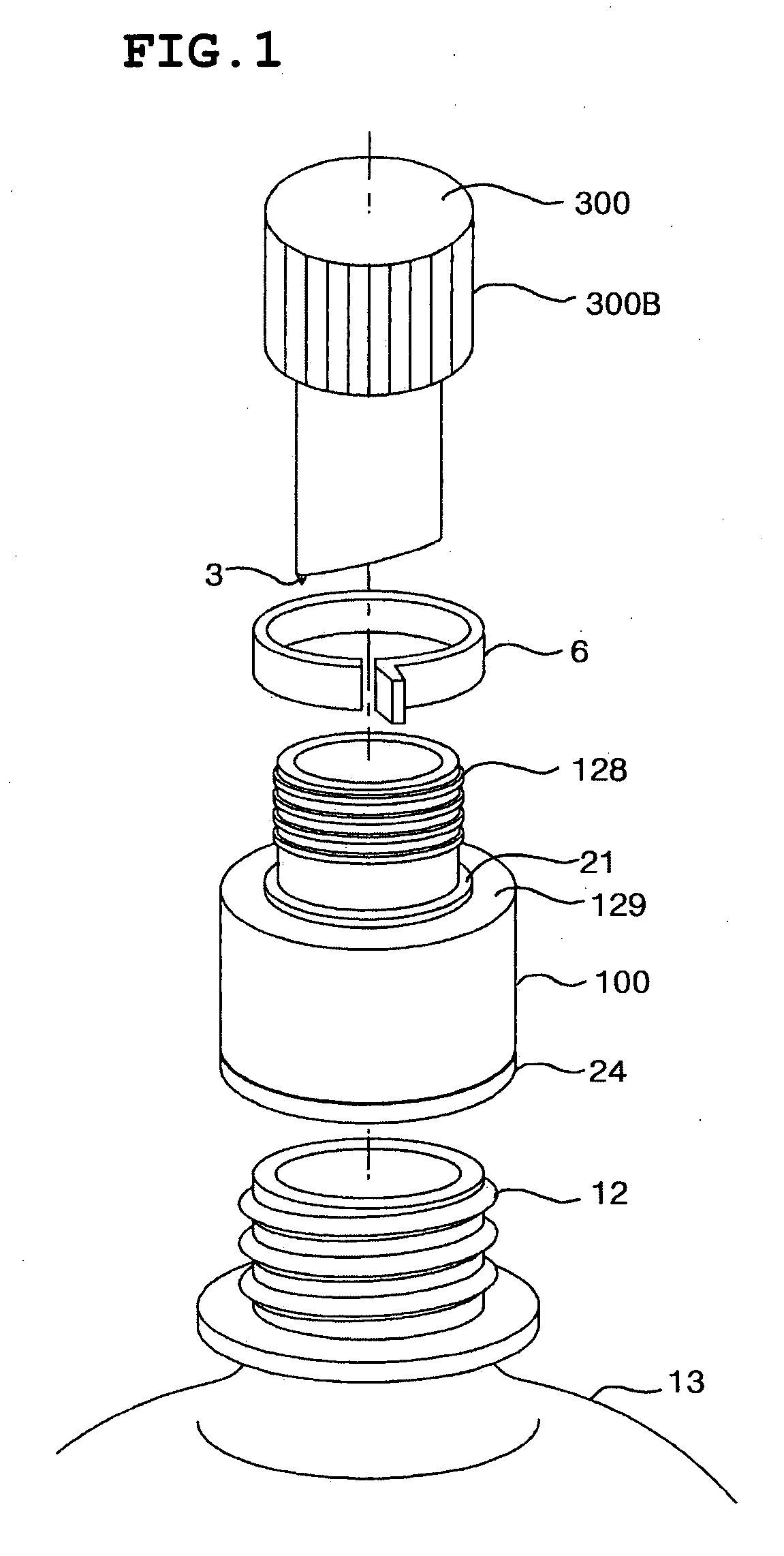

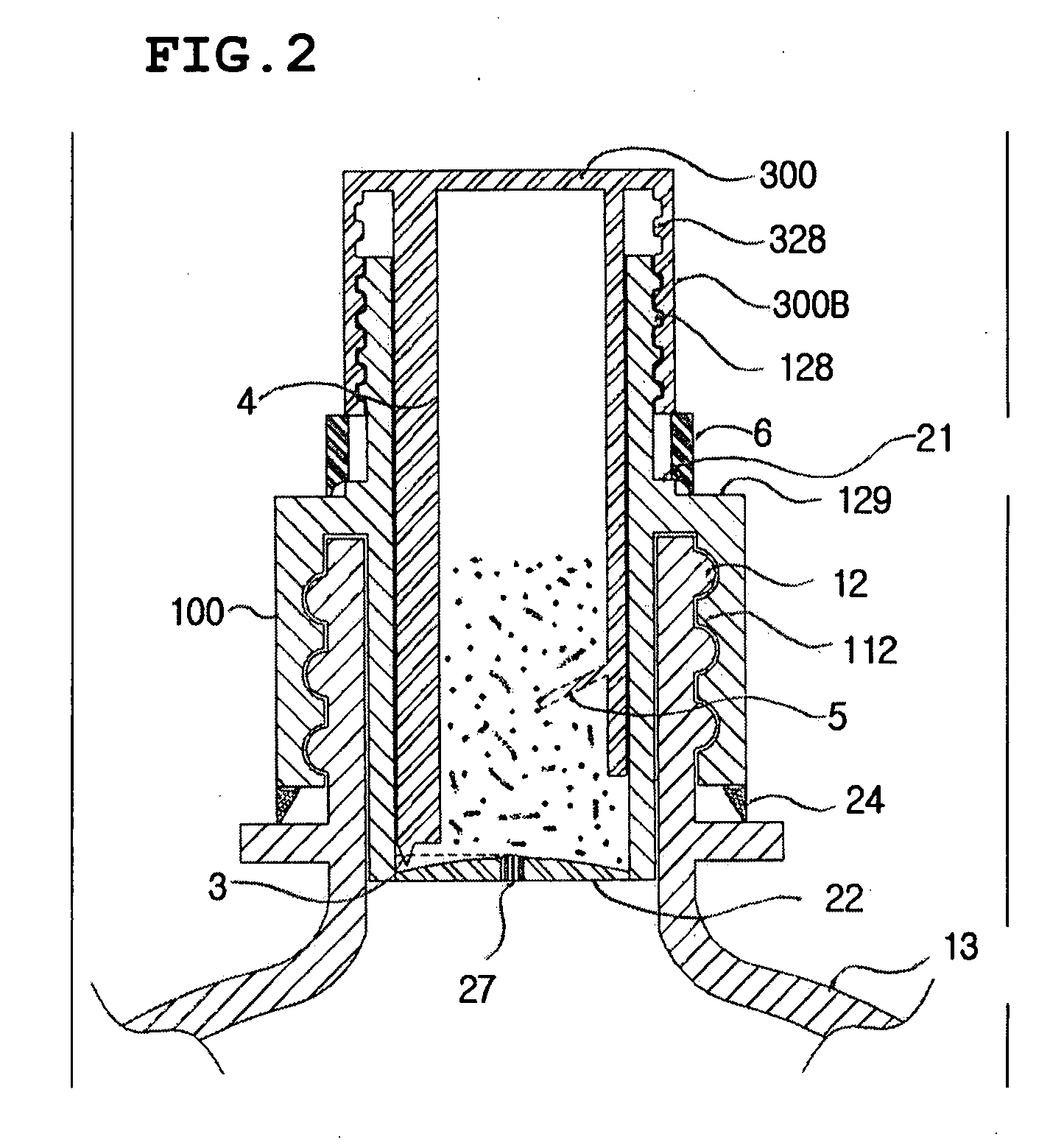

[0028]FIG. 5 is a sectional view illustrating a container cap according to the preferred embodiment of the present invention. FIG. 6 is a sectional view of a critical part of the container cap of the present invention.

[0029]As shown in the drawings, the container cap of the present invention includes a base cap member 100, which is coupled to an opening of a container, an operational cap member 300, which is coupled to the upper end of the base cap member 100 and a cutting blade 3, and an openable sheet, which is the bottom of an adjunct receiving part 77-3. The openable sheet includes a weight member 77, which has a diameter less than that of an arc part, along which the bottom of the adjunct receiving part 77-3 is cut, at least one connection rib 77-2, which connects the weight member 77 to the lower edge of the adjunct receiving part 77-3, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com