6.8 liter aluminium inner lining carbon fiber full winding composite gas cylinder

A carbon fiber and inner lining technology, applied in the field of 6.8-liter aluminum-lined carbon fiber fully wound composite gas cylinders, can solve the problems of randomness, low fatigue life of composite gas cylinders, and inability to maximize the overall strength of the composite gas cylinder structure, etc. , to achieve the best safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

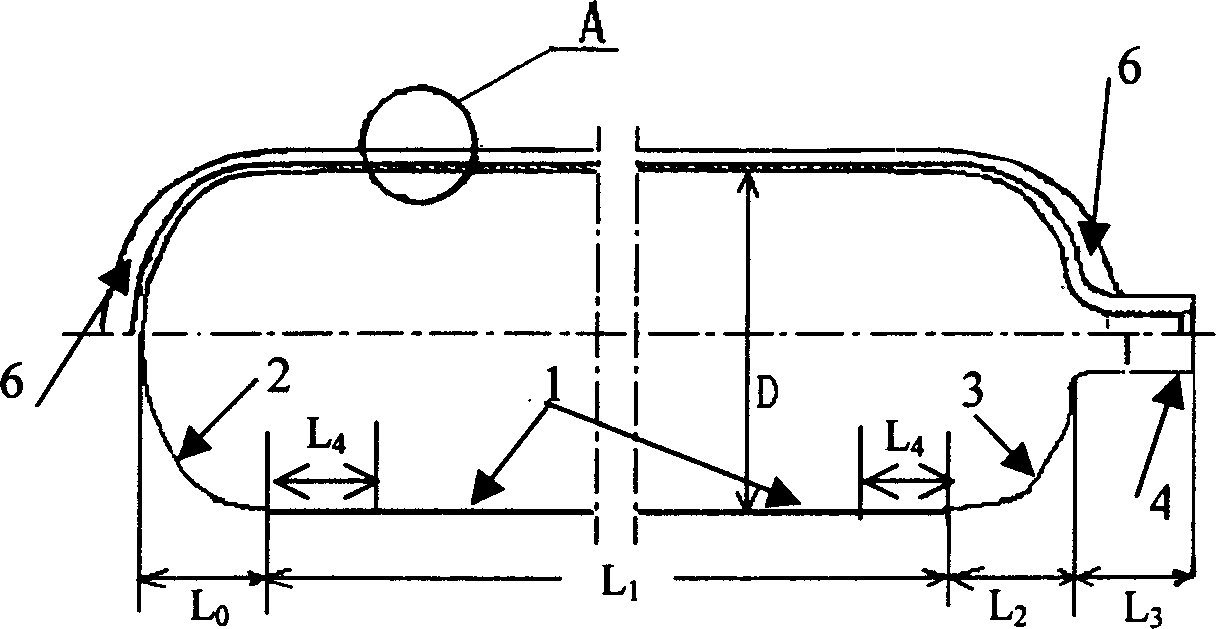

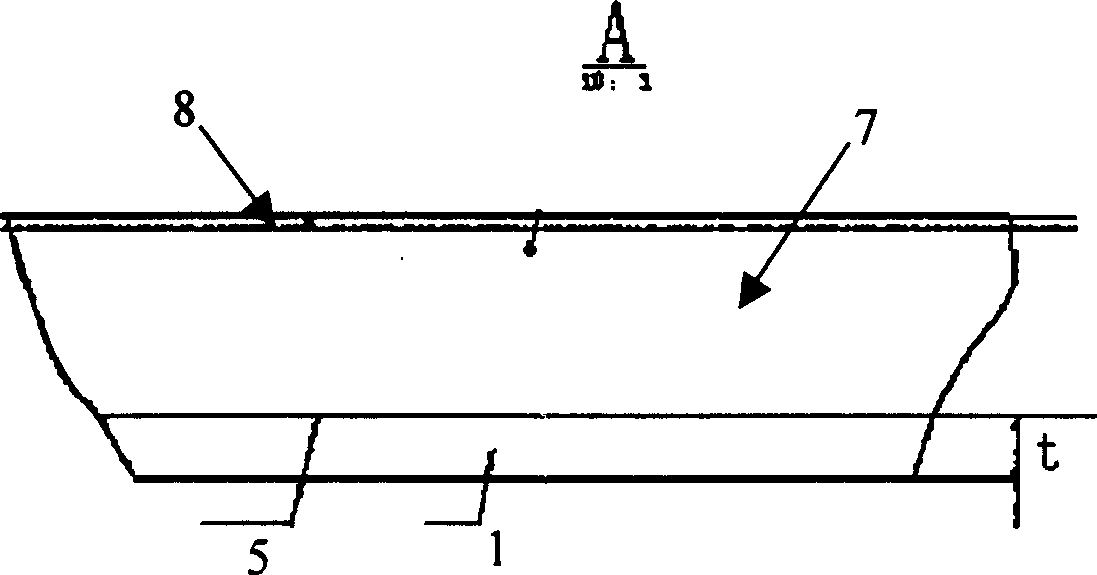

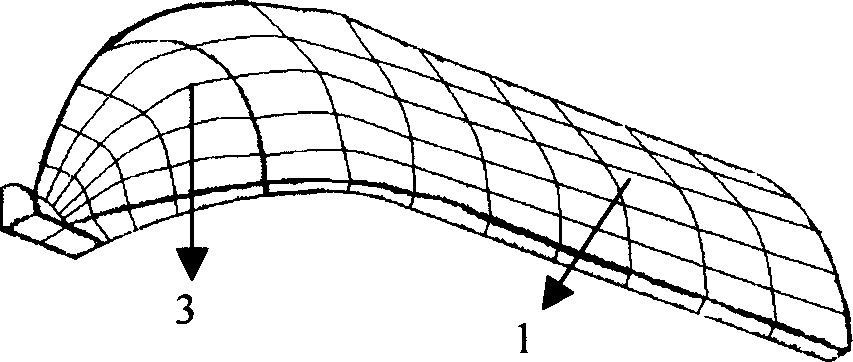

[0023] The 6.8-liter aluminum-lined carbon fiber full-winding composite gas cylinder of the present invention uses the aluminum liner as the mandrel, utilizes the fiber winding machine, and completely winds the T700-12KC carbon fiber on the aluminum liner according to the optimally designed laying sequence. structured as figure 1 and figure 2 shown. The specific implementation method is:

[0024] 1) figure 1 and figure 2 In , the structural dimensions of the aluminum lining shown are respectively taken as:

[0025] The length of cylinder 1 is L 1 =414mm, inner diameter D=140mm, sagittal height L of the tail end 2 of the elliptic surface 0 =0.31D, the sagittal height L of the neck 3 of the elliptic surface 2 =0.3D, including the length L of the bottle mouth 4 with M18 internal thread 3 =55mm, wall thickness t=1.8mm, guarantee that the volume of composite gas cylinder of the present invention is 6.8 liters.

[0026] 2) Apply a thin layer of polyurethane varnish on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com