Sock having part for preventing slipping-down phenomenon of sock

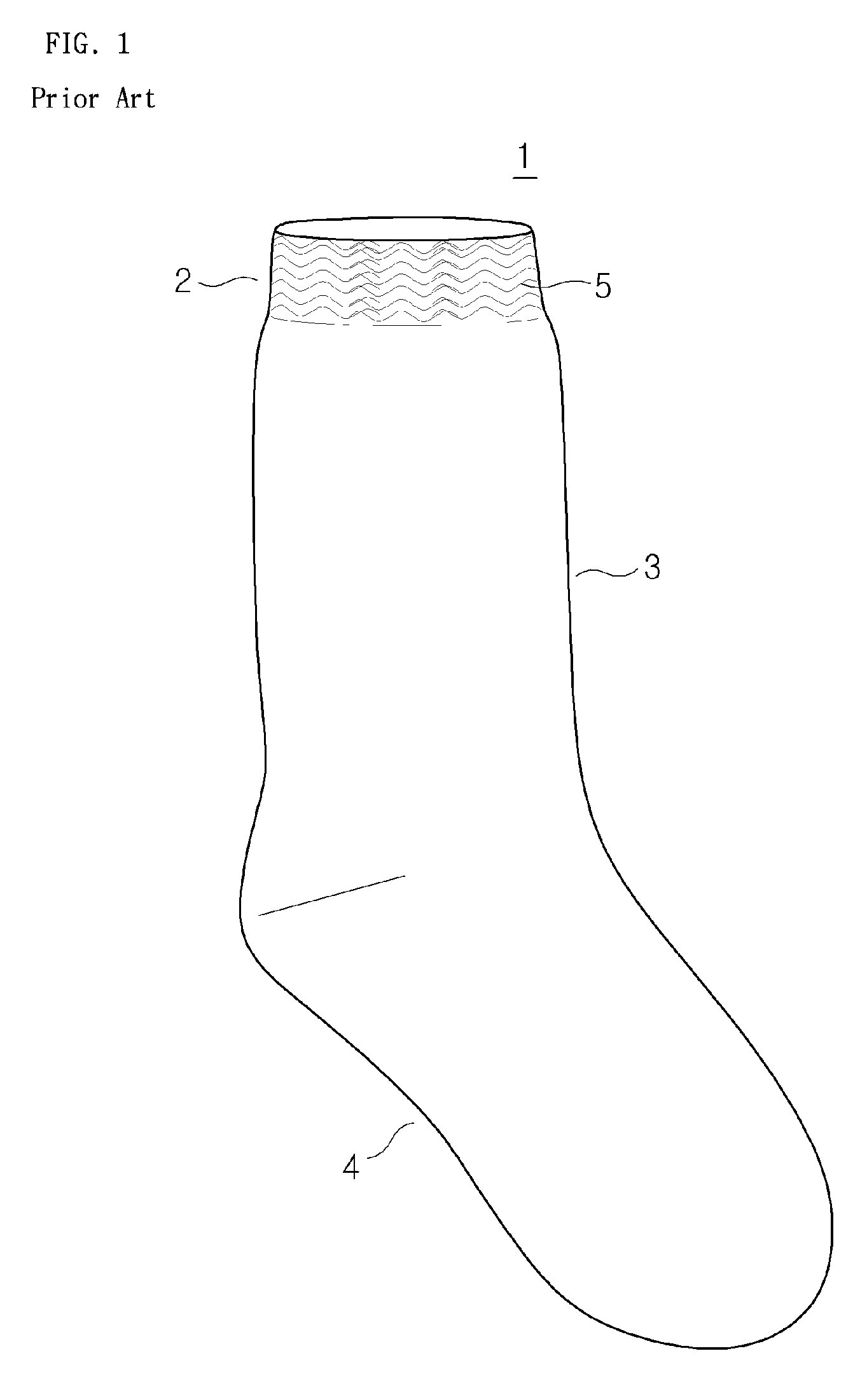

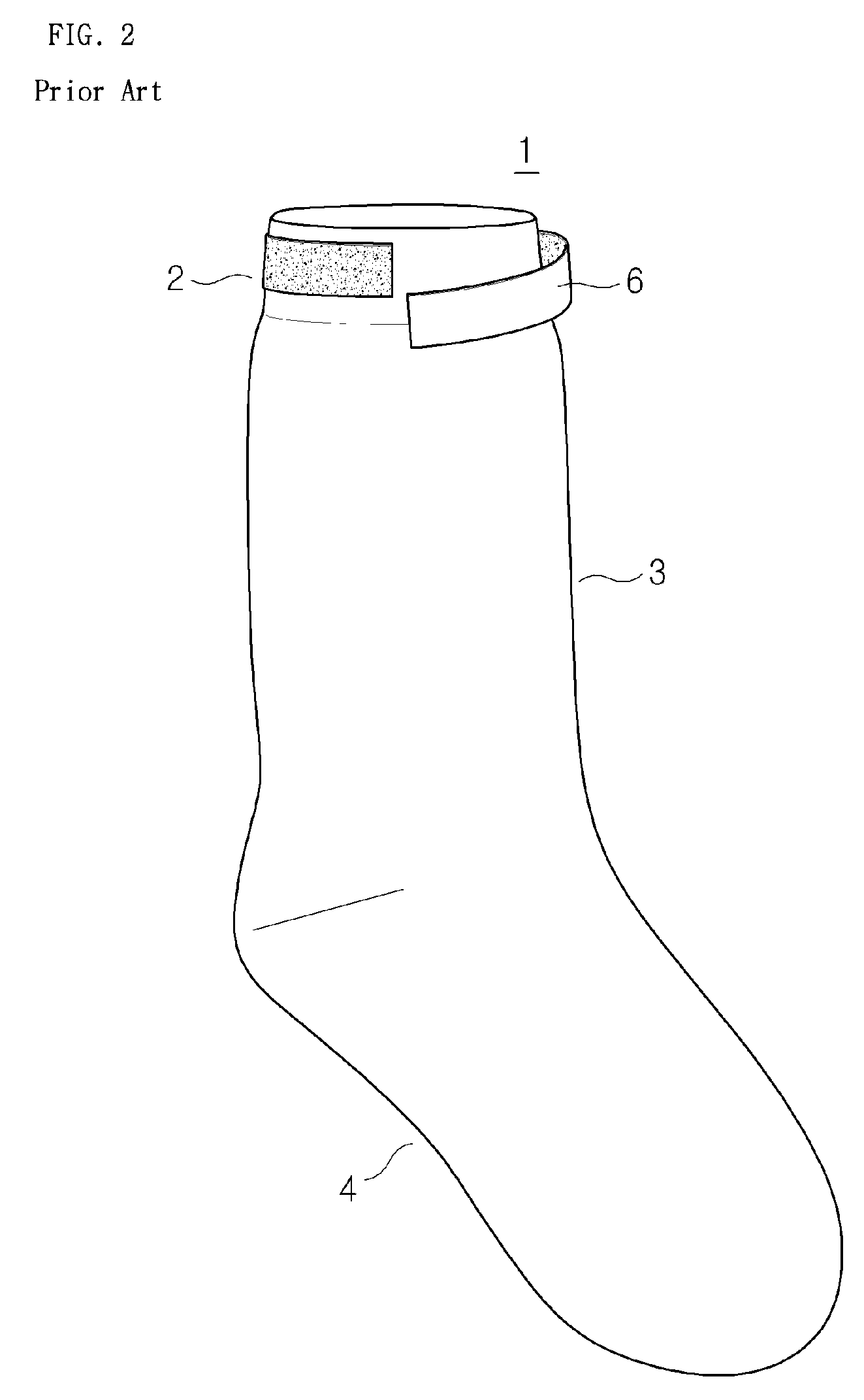

a technology of sock and sock body, which is applied in the direction of socks, pantyhose, hosiery, etc., can solve the problems of velcro band being exposed to the outside of socks, and clothes being caught by clothes, etc., to prevent slipping down phenomenon of socks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0022]FIG. 3 is a perspective view illustrating a sock according to an embodiment of the present invention, FIG. 4A is a cross sectional view illustrating a coating part with respect to a sock of which a neck part is formed of dual layers in the socks of FIG. 3, FIG. 4B is a cross sectional view illustrating a coating part with respect to a sock of which a neck part is formed of a single layer in the socks of FIG. 3, and FIGS. 5A and 5B are perspective views illustrating a sock according to another embodiment of the present invention.

[0023] As shown in FIG. 3, a sock 1 includes a foot sole part 4, an upper part 3, and a neck part 2. A slipping-down prevention part 10 is attached at an inner side surface of the neck part 2 of the sock 1 in order to prevent the sock 1 from being slipped down in a state that a user wears the socks 1.

[0024] Here, the slipping-down p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com