Waste plastic crushing device

A crushing device and waste plastic technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems that affect the work efficiency of workers, low crushing efficiency, long residence time, etc., to improve crushing efficiency and reduce crushing costs , Reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

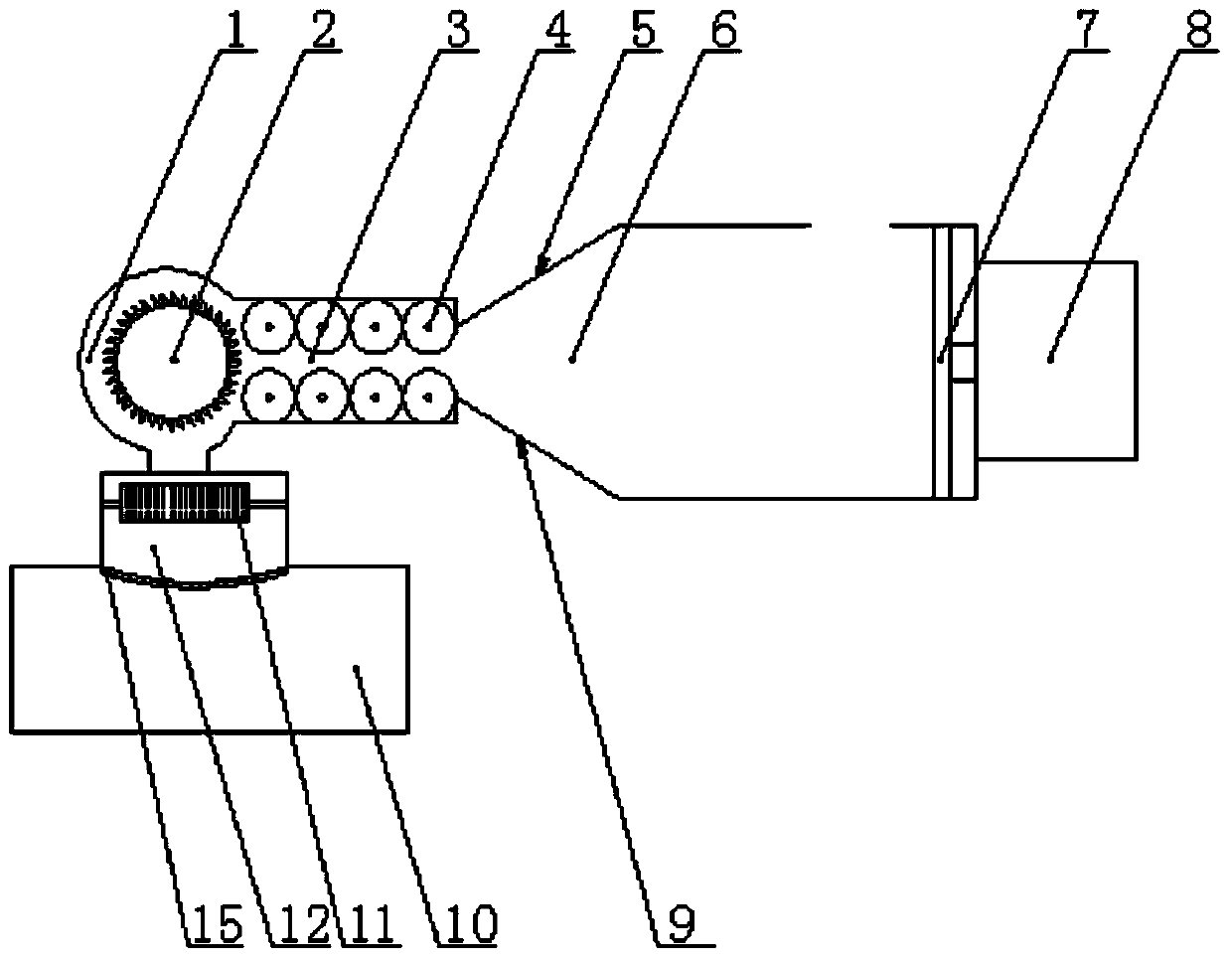

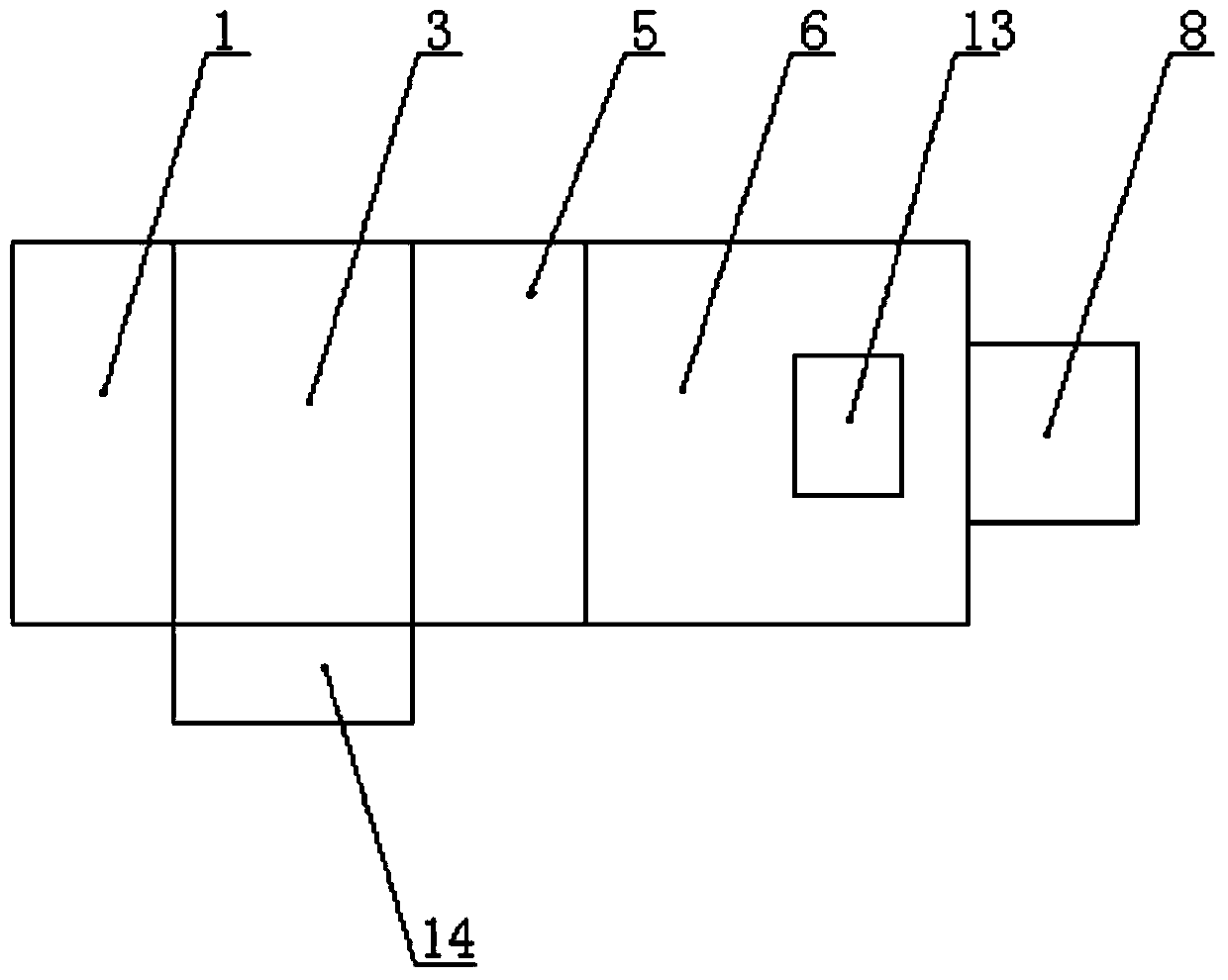

[0016] The waste plastic crushing device is composed of a compression chamber 6, a heating chamber 3, a crushing chamber, and a discharge bin 10 connected in sequence. The top of the compression chamber is provided with a feed port 13, and the compression chamber and the heating chamber pass through the upper platen 5 and the lower platen 9. One side of the compression chamber is equipped with a briquetting block 7 capable of reciprocating movement to the opposite side, and a driving device 8 is installed on the side of the compression chamber on the outer wall of the compression chamber, and the driving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com