Concrete beforehand pore-forming static breaking technology

A static crushing and concrete technology, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of reducing the cost of concrete crushing, large impact on the surrounding environment, and easy spray holes to hurt people, etc., to save crushing costs, avoid noise, The effect of shortening the demolition period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described, and this concrete crushing method is very clear to the professional people who are engaged in building demolition.

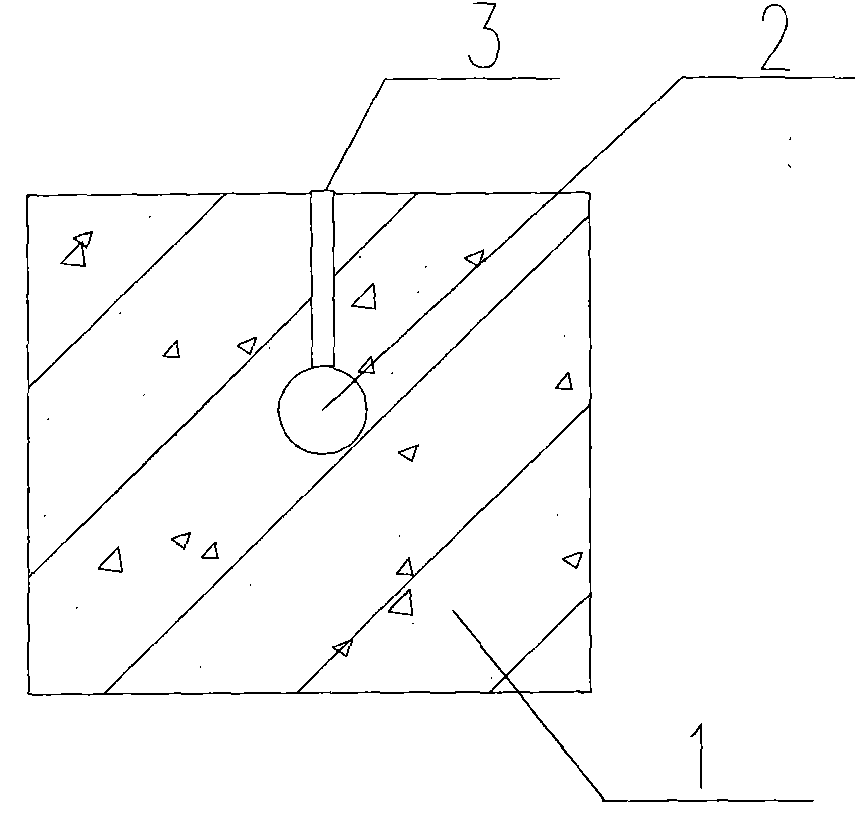

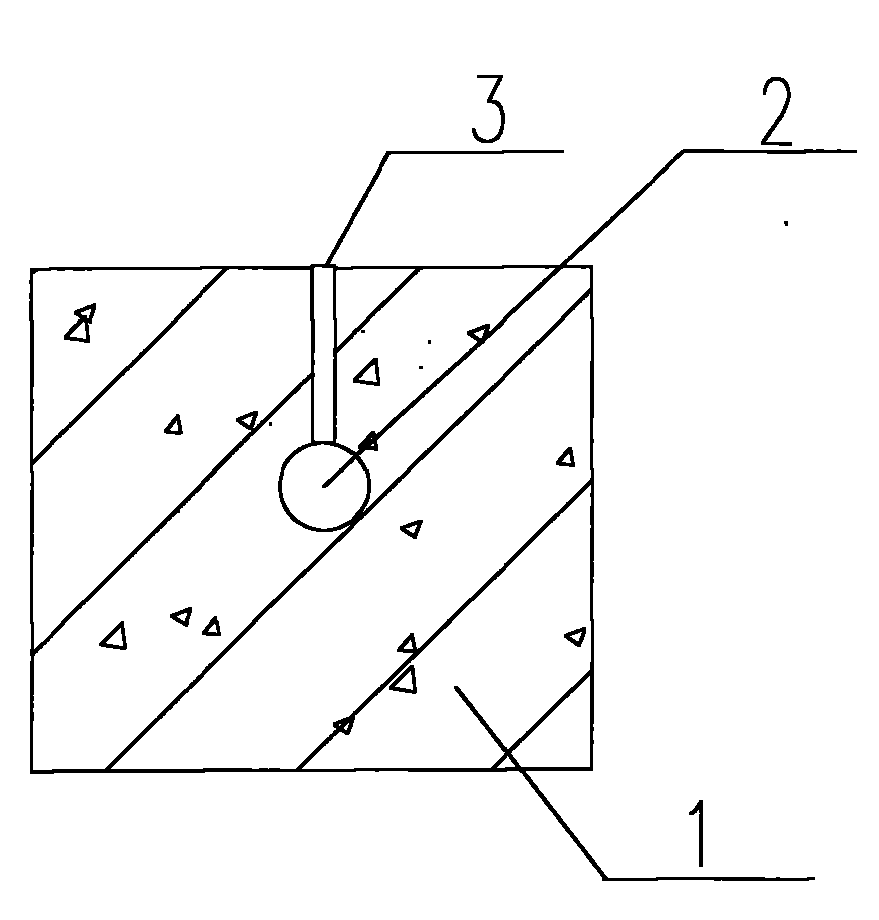

[0021] a, pre-embedded container 2, such as figure 1

[0022] Design the size, shape, quantity and position of the container 2 according to the cross-sectional form of the concrete member 1 and the reinforcement, etc., and embed it in the member 1 before concrete pouring. Above the container 2 is the orifice 3, which extends out of the member. To show the signs, the concrete vibrating process should avoid damage, move the container 2 and the orifice 3, the inner diameter of the orifice 3 is smaller than the inner diameter of the container 2.

[0023] b. Infuse expansion agent

[0024] When the concrete needs to be removed, first check whether the orifice 3 and the container 2 are damaged. If it is blocked, use a steel drill or an electric hammer to open it, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com