Iron phosphate ion sieve for selectively extracting Li and application thereof

A technology of ion sieve and iron phosphate, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of large dissolution loss, short adsorbent life, unfavorable industrial application, etc., and achieve low production cost, low price, and easy industrialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

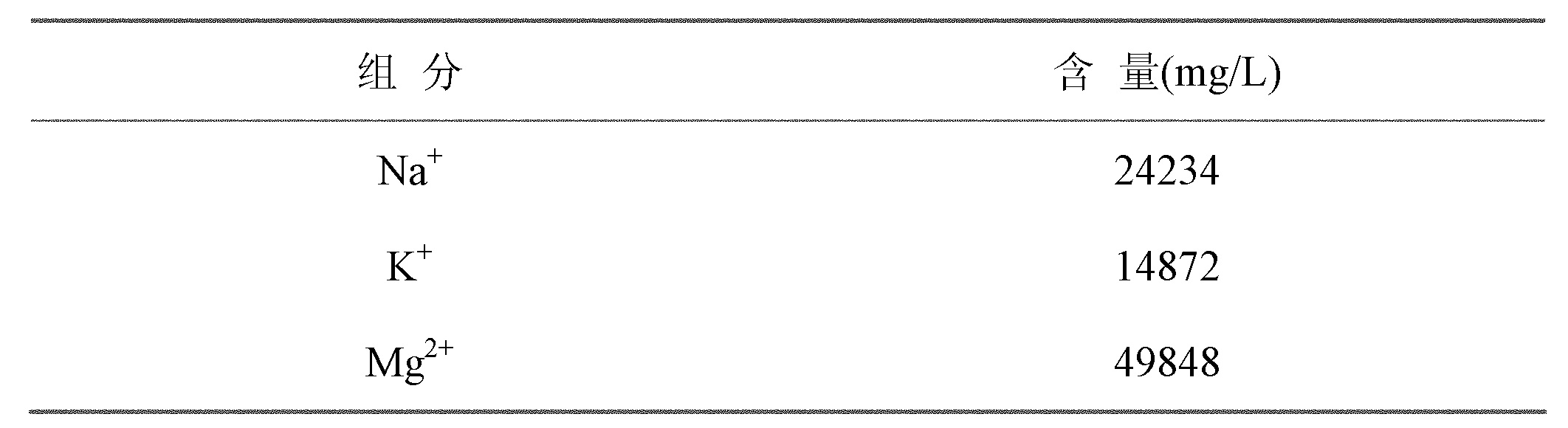

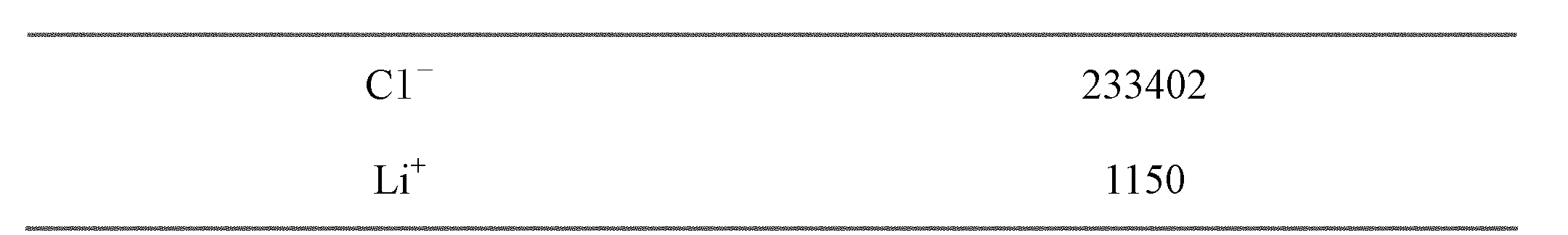

[0018] 100gFePO 4 The ion sieve is placed in 50L of a salt lake brine. The main components and contents of the brine are shown in the following table:

[0019]

[0020]

[0021] will be mixed with 100g FePO 4 The 50L salt lake brine of the ion sieve was heated and stirred, and the temperature of the solution was controlled at 80°C; 50mL of 10% hydrazine aqueous solution was slowly added dropwise, stirred and reacted for 1h, and then filtered, the Li in the brine + Enter FePO 4 In the ion sieve, the solid phase is LiFePO 4 , Li in solution + The concentration is reduced to 1.08g / L, FePO 4 The adsorption capacity of ion sieve to Li is about 35 mg / g; the filtered LiFePO 4 Place in 1L of 10% NaCl solution for heating and stirring, control the temperature of the solution at 40°C, slowly add 25mL of 25% hydrogen peroxide dropwise, stir for 1 hour and then filter, LiFePO 4 Li in + Into the NaCl solution, the solid phase is transformed into FePO 4 Ion sieve, Li in delith...

Embodiment 2

[0023] 200g Al 0.02 Fe 0.98 PO 4 The ion sieve material was loaded into an ion exchange column, and a mixed solution was prepared with 90 mL of 10% hydrazine aqueous solution and 20 L of salt lake brine. The main components and contents of the salt lake brine were the same as in Example 1. Pass the mixed solution through the ion-exchange column at a speed of 100mL / min; after about 75min, the ion-exchange column leaks through; after washing the ion-exchange column with distilled water, use 2L of a solution containing 30g / LNaCl and 6g / L hydrogen peroxide to 100mL / min speed through the ion exchange column, oxidative desorption to obtain Li + 1L of solution with a concentration of 8.16g / L, Al 0.02 Fe 0.98 PO 4 The Li adsorption capacity of the ion sieve is about 40.8 mg / g.

Embodiment 3

[0025] 15gMn 0.02 Fe 0.98 PO 4 The ion sieve is placed in the brine chamber of the electrodialysis device, and 2L of a certain salt lake brine is added. The composition and content of the salt lake brine are shown in the following table:

[0026]

[0027]

[0028] 15g LiNi 0.02 Fe 0.98 PO 4 Place the lithium salt chamber in the electrodialysis device, add 100mL of 30g / L NaCl solution; separate the brine chamber and the lithium salt chamber with an anion exchange membrane, and use LiNi 0.02 Fe 0.98 PO 4 as the anode, Mn 0.02 Fe 0.98 PO 4 As the cathode, a voltage of 0.8V is applied across the electrodes, and after maintaining for 15h, the Li in the brine chamber + Concentration decreased to 286mg / L, Mg 2+ The concentration is about 17993mg / L, Mn 0.02 Fe 0.98 PO 4 to Li + The adsorption capacity is about 28.5mg / g, for Mg 2+ The adsorption capacity is about 0.93mg / g; Li + The concentration is about 4.28g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com