Method for recycling nickel-cobalt-manganese ternary anode material

A technology of ternary materials and positive electrode materials, which is applied in the field of waste battery recycling, can solve the problems of component segregation, poor separation effect, and inability to ensure the uniformity of oxides, etc., and achieve the effect of promoting popularization and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

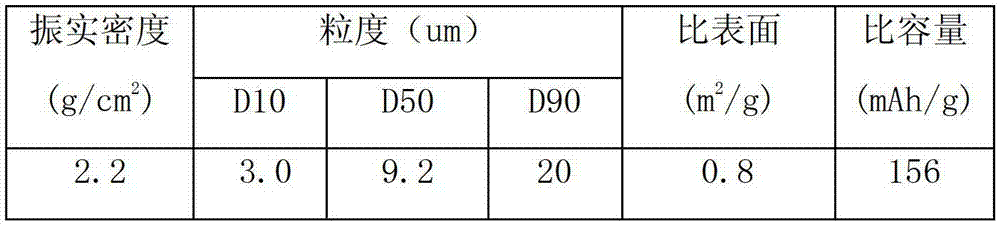

[0033] Embodiment 1 adopts the method of the present invention to recycle nickel-cobalt-manganese ternary positive electrode material

[0034] Discharge the residual power of the waste nickel-cobalt-lithium-manganese-oxide battery, disassemble the battery, take out the positive electrode sheet, and recycle the battery case according to aluminum shell, steel shell, plastic, etc.; calcinate the nickel-cobalt lithium-manganese oxide positive electrode sheet at 1000°C for 0.5h.

[0035]Take 100 kg of the calcined nickel-cobalt lithium manganese oxide positive plate, stir and leaching with 10wt% sulfuric acid, add 1 kg of sodium thiosulfate during the leaching process, and filter to obtain a mixture of nickel sulfate, cobalt sulfate, manganese sulfate, aluminum sulfate and lithium sulfate. solution. The pH value of the mixed solution was adjusted to 4.5 to form aluminum hydroxide precipitate, and the aluminum hydroxide was removed by filtration to obtain a mixed solution of nickel ...

Embodiment 2

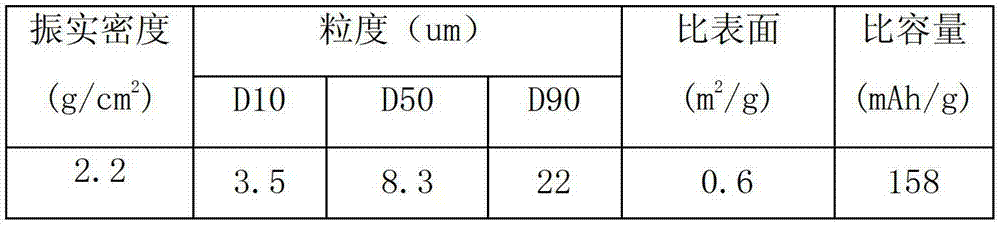

[0039] Embodiment 2 adopts the method of the present invention to recycle nickel-cobalt-manganese ternary positive electrode material

[0040] Discharge the residual power of the waste nickel-cobalt-lithium manganese oxide battery, disassemble the battery, take out the positive plate, and recycle the battery case according to aluminum shell, steel shell, plastic, etc.; bake the nickel-cobalt lithium manganese oxide positive plate at 700°C for 3 hours.

[0041] Take 100 kg of the calcined nickel-cobalt lithium manganese oxide positive electrode sheet, and use 15wt% sulfuric acid to stir and leach, add 0.8 kg of sodium thiosulfate during the leaching process, and obtain nickel sulfate, cobalt sulfate, manganese sulfate, aluminum sulfate and lithium sulfate by filtering after leaching mixture. The pH value of the mixed solution was adjusted to 5 to form aluminum hydroxide precipitate, and the aluminum hydroxide was removed by filtration to obtain a mixed solution of nickel sulfat...

Embodiment 3

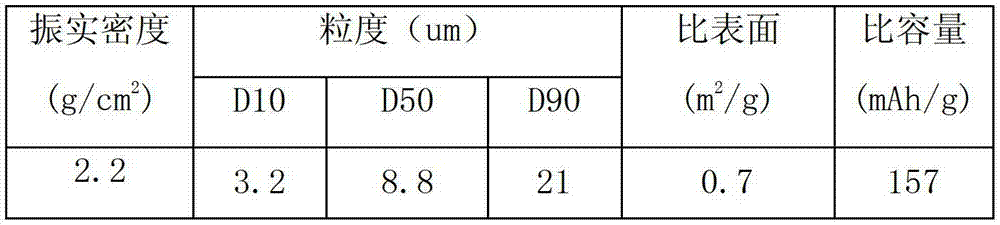

[0045] Embodiment 3 adopts the method of the present invention to recycle nickel-cobalt-manganese ternary positive electrode material

[0046] Discharge the residual power of the waste nickel-cobalt-lithium-manganese-oxide battery, disassemble the battery, take out the positive electrode sheet, and recycle the battery case according to aluminum shell, steel shell, plastic, etc.; roast the nickel-cobalt lithium-manganese oxide positive electrode sheet at 400°C for 5 hours.

[0047] Take 100kg of the calcined nickel-cobalt lithium manganese oxide positive electrode sheet, and use 12wt% sulfuric acid to stir and leach, add 1.2kg of sodium thiosulfate during the leaching process, and filter to obtain nickel sulfate, cobalt sulfate, manganese sulfate, aluminum sulfate and lithium sulfate after leaching. mixture. The pH value of the mixed solution was adjusted to 6 to form aluminum hydroxide precipitate, and the aluminum hydroxide was removed by filtration to obtain a mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com