Method for recovering zinc oxide in Zn-containing dust treatment by rotary hearth furnace

A technology of dust recovery and rotary hearth furnace, which is applied in the field of zinc-containing dust treatment and zinc oxide recovery from zinc-containing dust by rotary hearth furnace, which can solve the problem of low zinc recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

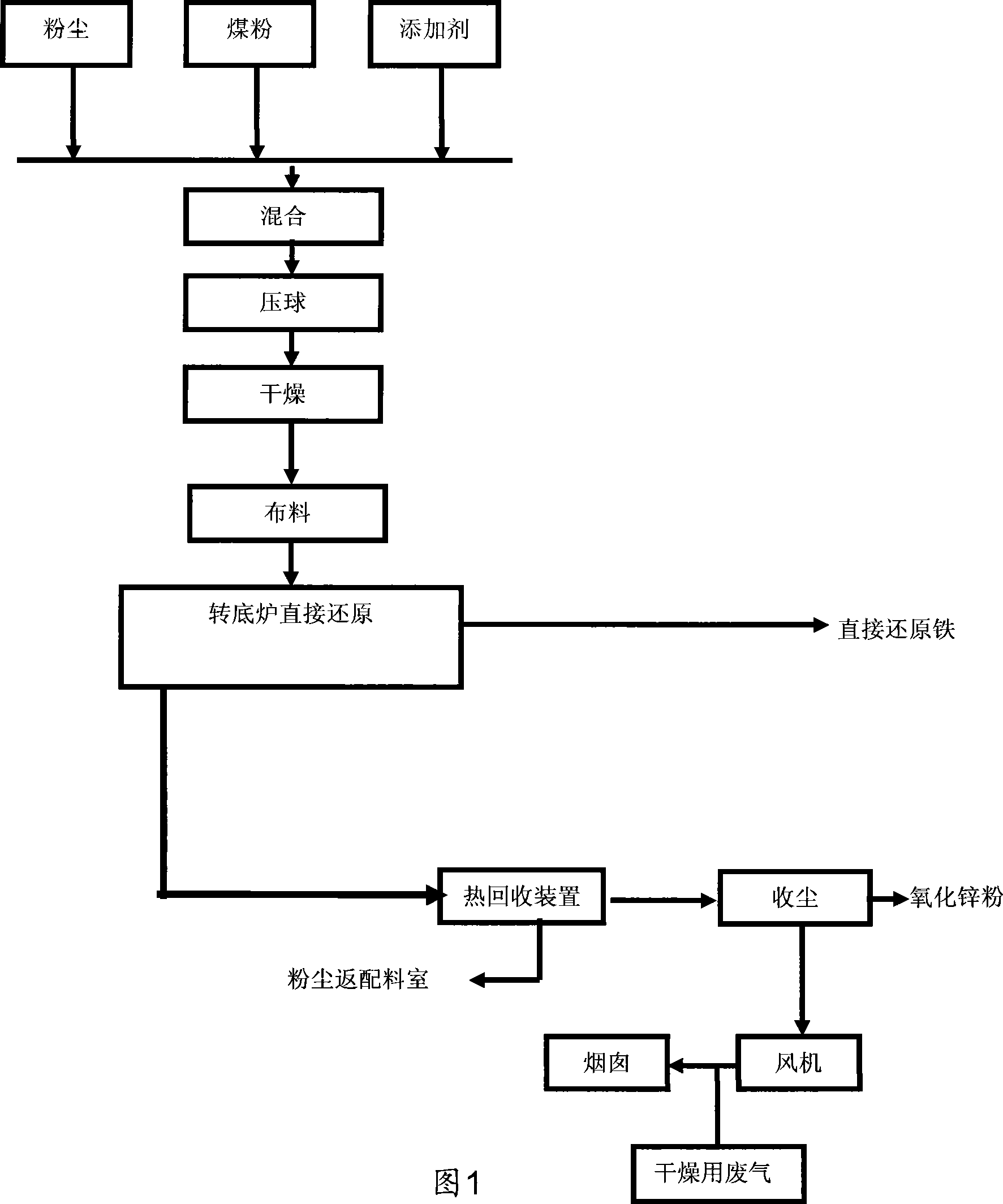

[0015] The method for reclaiming zinc oxide from zinc-containing dust in the regenerative rotary hearth furnace of the present invention, its preferred specific implementation is as shown in Figure 1, comprising the steps:

[0016] Firstly, raw material preparation is carried out, and the raw materials such as coal, iron and steel plant dust sludge (zinc-containing dust), additives are proportioned according to the following parts by weight:

[0017] Coal: 20-30 parts;

[0018] Zinc-containing dust: 70-80 parts;

[0019] Additives: 2 to 5 parts.

[0020] Among the above raw materials,

[0021] Coal: Non-coking coal can be used, the ash content of pulverized coal is ≤10%, the particle size is ≤0.1mm, and coke oven coal can also be used;

[0022] Zinc-containing dust: blast furnace, converter or electric furnace dust can be used, or a mixture of various dusts, with a particle size of ≤0.1mm and a moisture content of ≤6%;

[0023] Additives: including solvents and organic adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com