Graphite purification and graphitizable high temperature vertical continuous induction heating furnace

An induction heating furnace, graphite purification technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of complex process, environmental pollution, low recovery rate, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

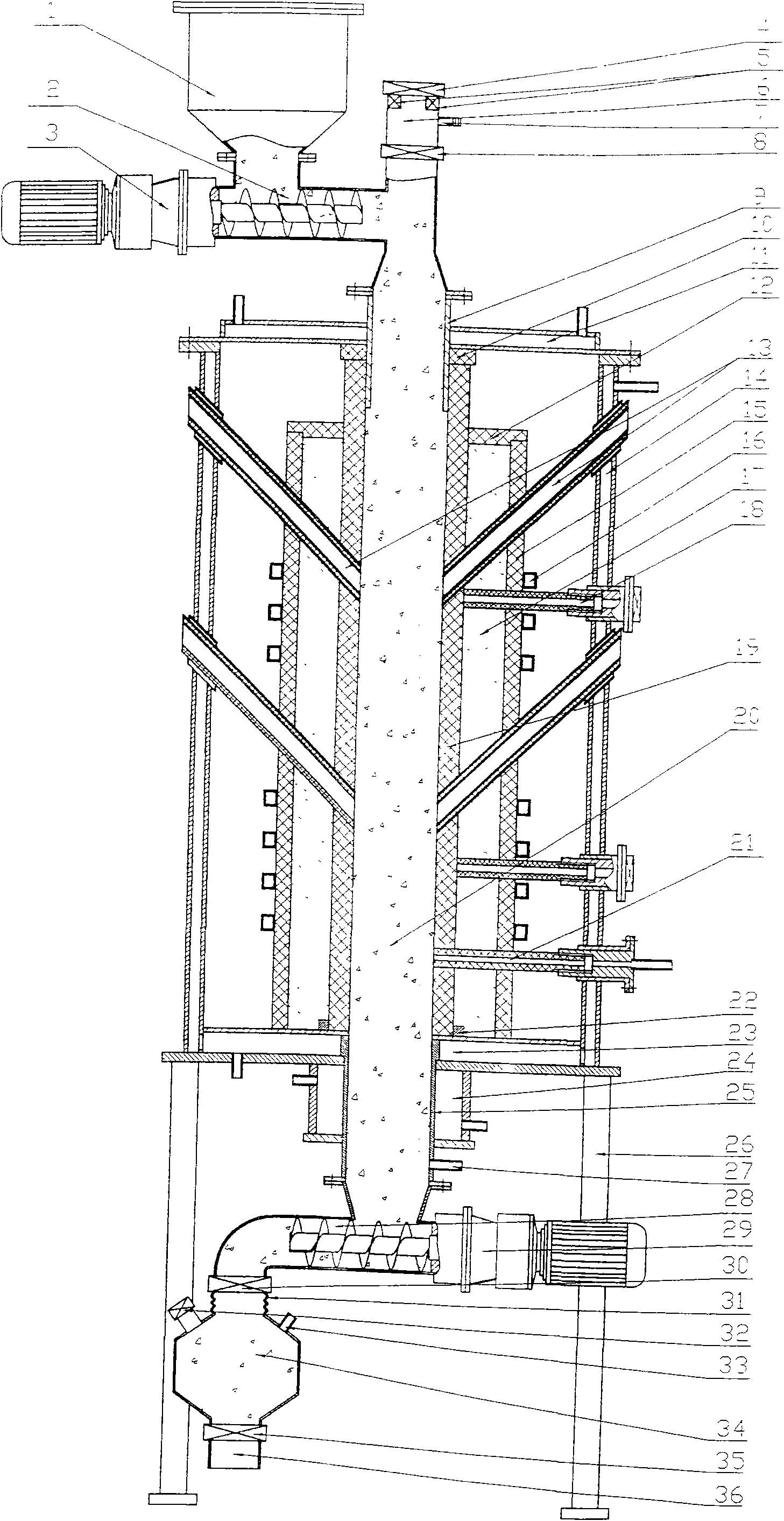

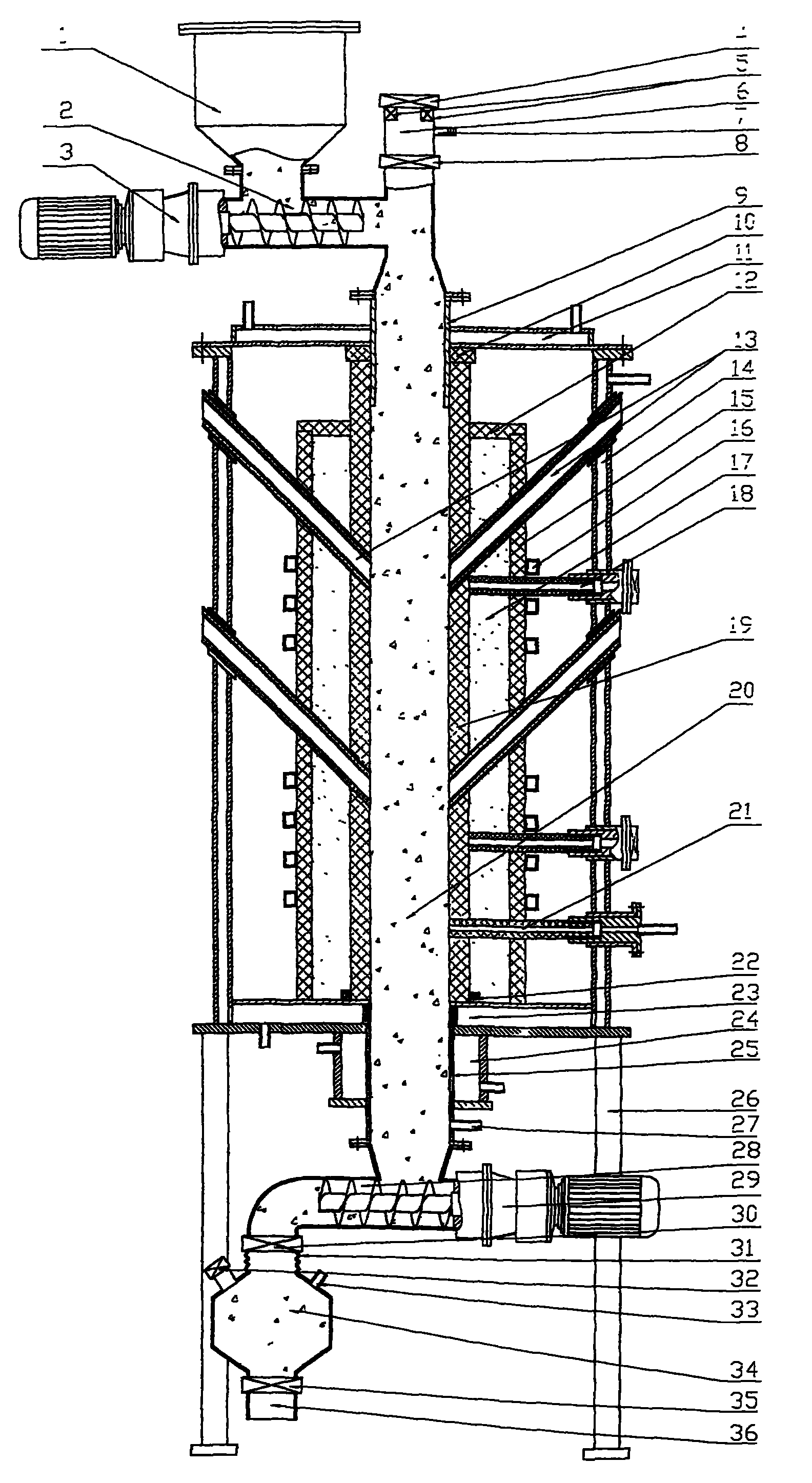

[0021] Referring to the accompanying drawings, a graphite purification and graphitization high-temperature vertical continuous induction heating furnace includes a feeding device, a furnace body, a furnace 20, an induction heating coil 16, an observation window device, a supporting foot 26 and a discharge device, and is characterized in that :

[0022] The high-temperature vertical continuous induction heating furnace for graphite purification and graphitization is a vertical structure, and its furnace body is a vertical cylindrical barrel with a water-permeable interlayer structure composed of a base 23, an outer cylinder 14 and a furnace cover 11. Type furnace body, the base 23 and the furnace cover 11 are respectively provided with a central hole, and the furnace body is fixed on the supporting foot 26 by the base;

[0023] The furnace 20 is a furnace with a vertical cylindrical space. The upper end of the furnace 20 is provided with an upper T-shaped flange sleeve 9. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com