Rotary hearth furnace and method for treating lead and zinc smelting slag

A technology for rotary hearth furnace and smelting slag, applied in the field of metallurgy, can solve the problem that valuable elements cannot be comprehensively recovered, and achieve the effects of reducing equipment investment costs, improving economic benefits, and solving the problem of waste of valuable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

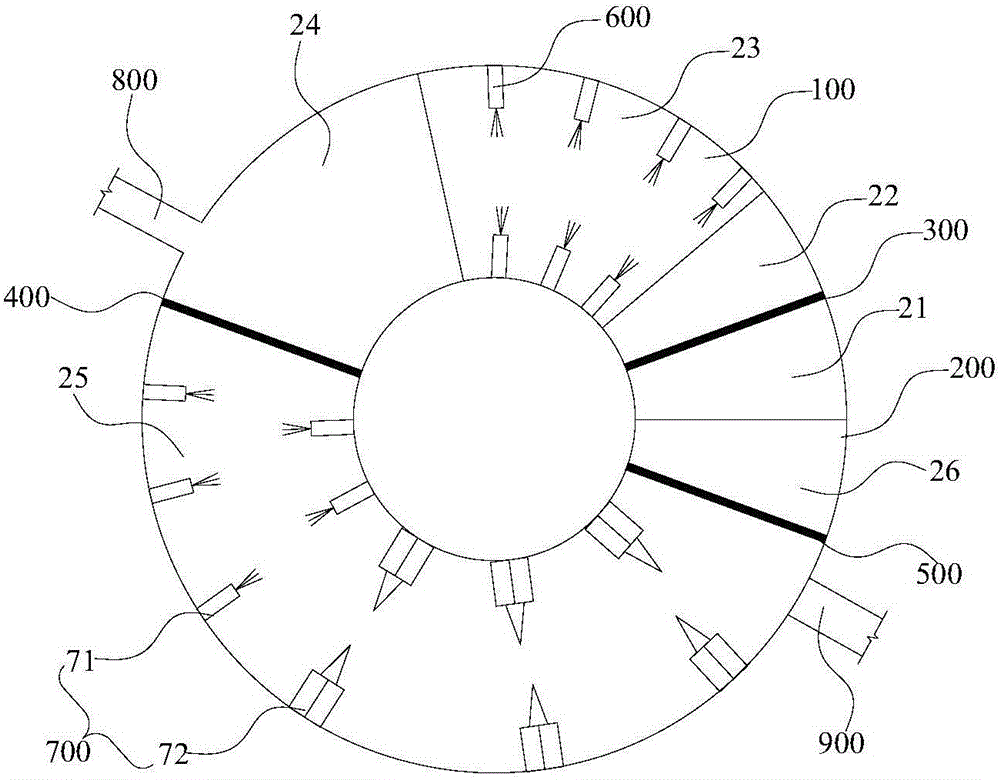

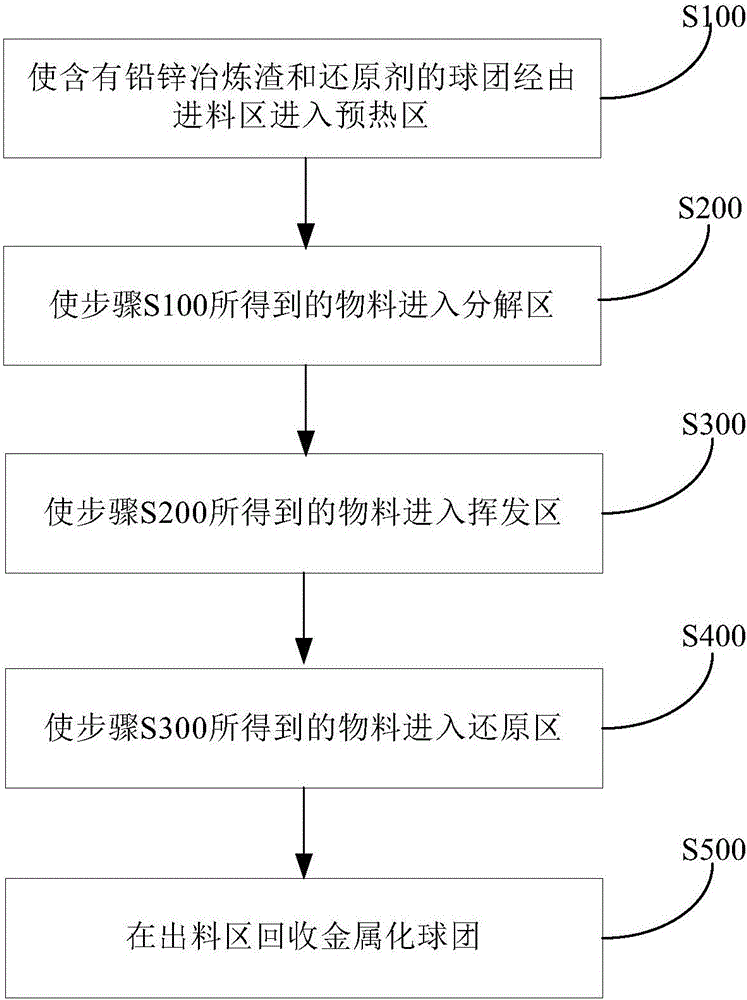

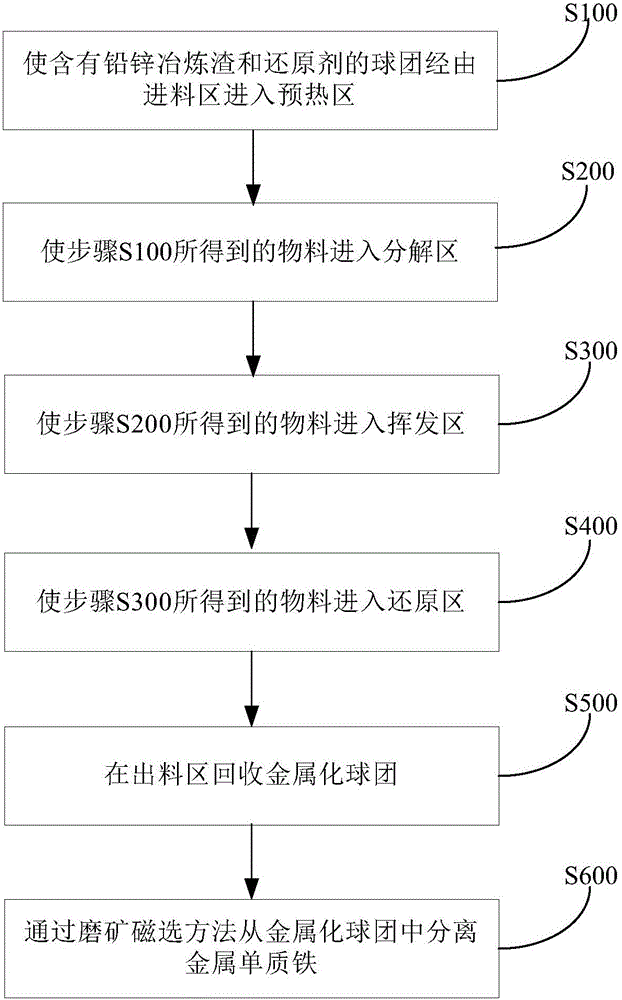

[0085] The sulfate lead-zinc smelting slag has the following components: TFe26.27wt%, Pb2.59wt%, Zn10.36wt%, In0.03wt%, S7.26wt%. The ratio of lead-zinc smelting slag to other raw materials is lead-zinc smelting slag: reducing agent: binder = 100:18:5, the mixed raw materials are agglomerated, and the dried pellets enter the rotary hearth furnace for processing. The pellets pass through the feeding zone, preheating zone, decomposition zone, volatilization zone, reduction zone and discharge zone in turn. In the preheating zone, the crystallization water in the pellets is volatilized first. The temperature in the preheating zone is 600°C, and The burner is not set separately, but is heated by the radiant heat of the ordinary burner in the decomposition zone; in the decomposition zone, the sulfate in the pellet is decomposed into sulfide (sulfur dioxide and sulfur trioxide) and metal oxides (lead oxide, oxide Zinc, indium oxide and iron oxide, etc.), the area is equipped with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com