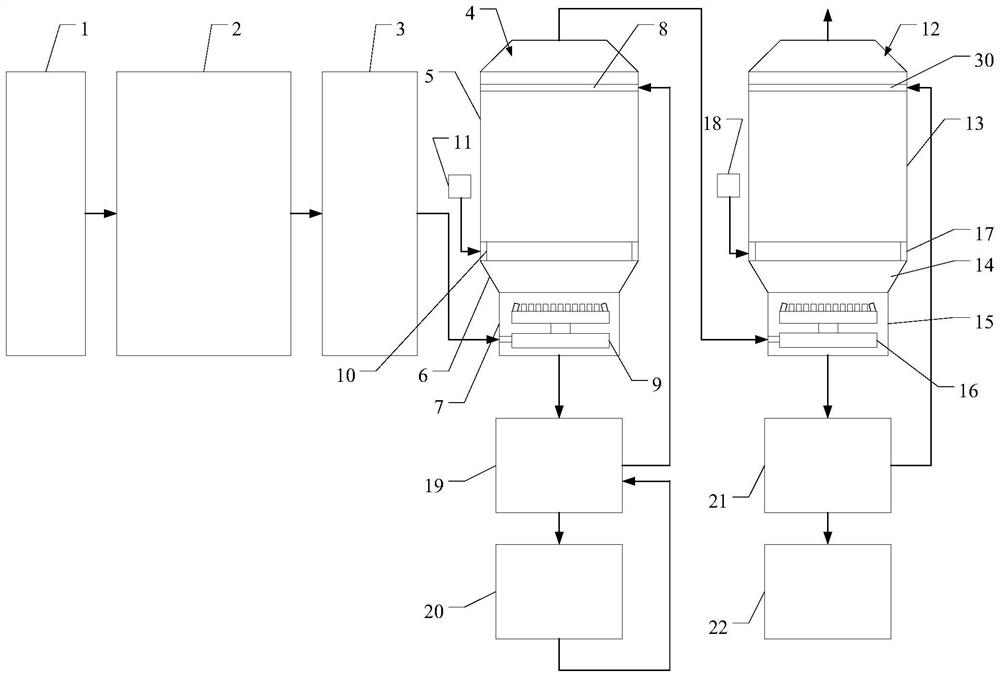

Two-stage binary flue gas treatment system

A flue gas treatment system and flue gas technology, applied in the direction of gas treatment, separation methods, and separation of dispersed particles, can solve problems that need to be improved, and achieve the effects of reducing environmental protection operating costs, improving desulfurization efficiency, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

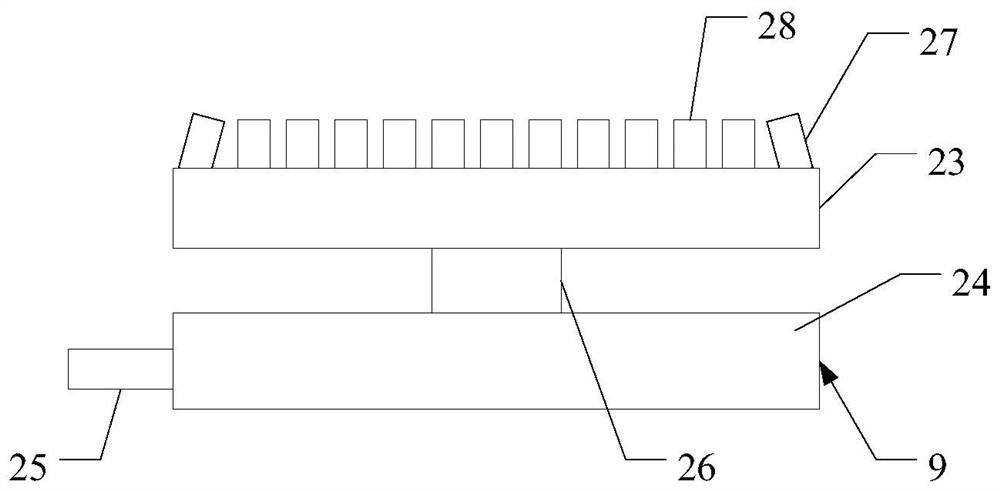

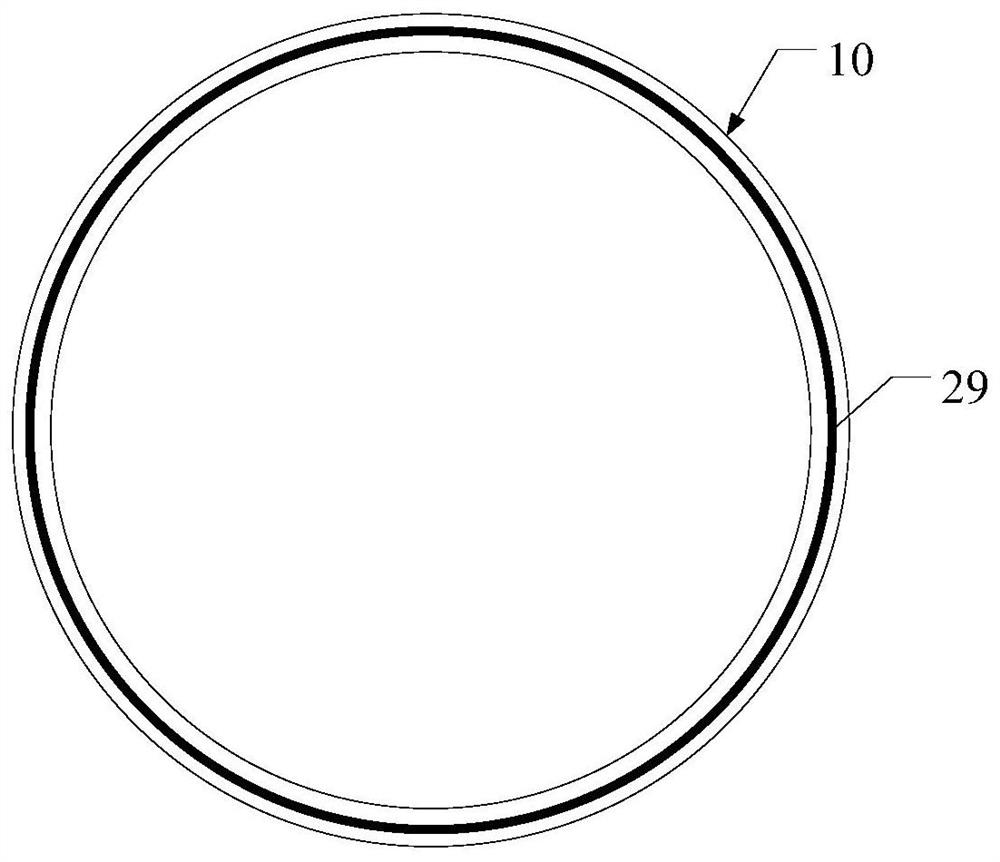

[0024] like figure 1 and figure 2As shown, the present invention provides a two-stage binary flue gas treatment system, including: heat exchange equipment 1; dust removal equipment, which is located on the downstream side of the heat exchange equipment 1 and connected to the heat exchange equipment; desulfurization tower 4. It includes the first tower body, the first flue gas uniform distribution device 9 and the first spray device 8, wherein the first tower body is composed of the first main body 5, the first enlarged diameter section 6 and the first lower part 7, the first main body 5 is connected to the first lower part 7 through the first enlarged diameter section 6; the first spray device 8 is arranged on the top of the first main body, and the first The liquid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com