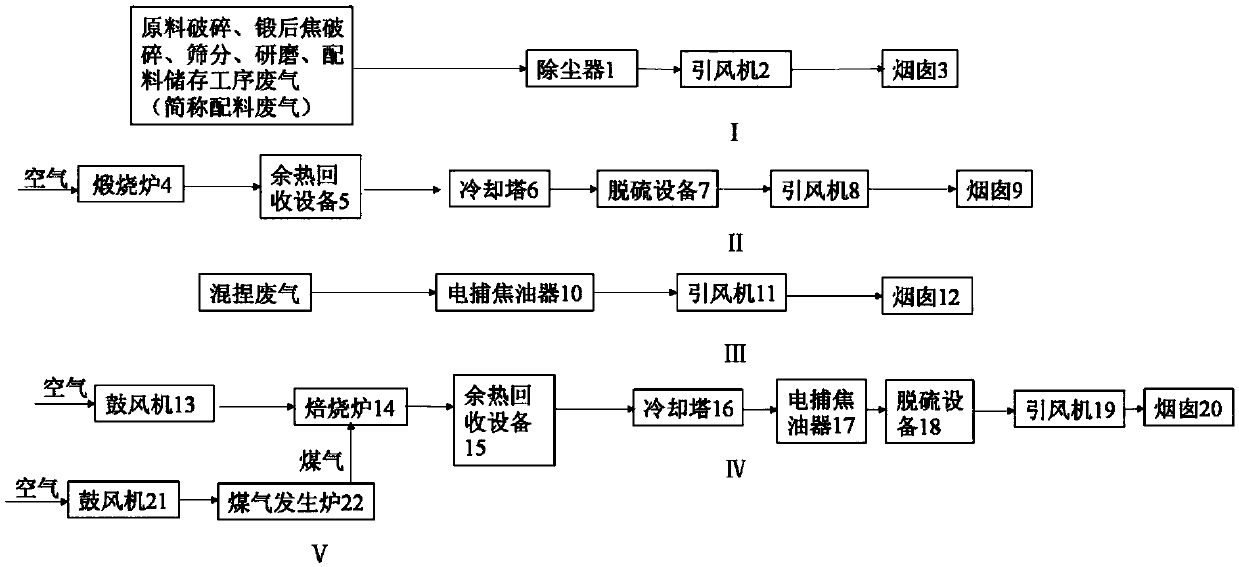

A carbon industry waste gas gradient and recycling emission reduction system and method

A waste gas and carbon technology, applied in the field of air pollution control, can solve problems such as waste gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

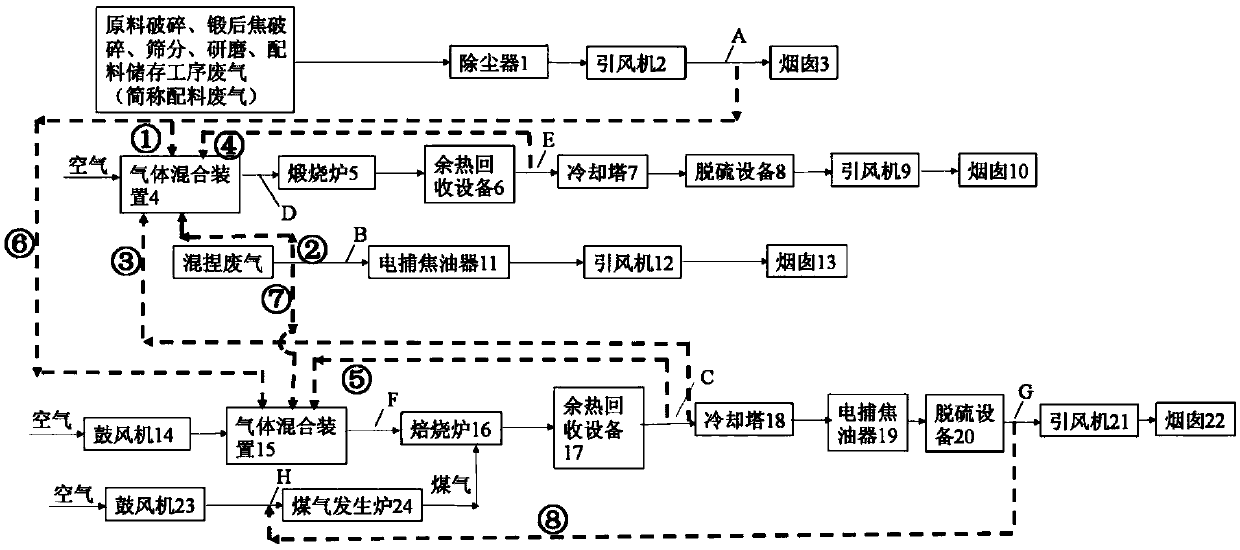

Method used

Image

Examples

Embodiment 1

[0069] Carbon anode product factory with an annual output of 60,000 tons of aluminum, the calcination process produces about 6000Nm of waste gas 3 / h, kneading waste gas about 1100Nm 3 / h, batching waste gas is about 17000Nm 3 / h, roaster exhaust gas is about 22000Nm 3 / h, the air volume required by the gasifier is about 2000Nm 3 / h. By adopting the system of the present invention, all the batching waste gas and kneading waste gas can be used in the roaster, 17% of the roaster waste gas is used for the roaster by self-circulation, and 27% of the roaster waste gas is used for the calciner. In addition, part of the waste gas discharged from the roaster About 2000Nm 3 / h can be circulated to the gas generator. Compared with the original exhaust gas purification system, in general, the present invention can reduce the amount of exhaust gas by at least about 30000Nm 3 / h, the amount of exhaust gas is reduced by about 65%, SO 2 Emission reduction about 12.0t / year, NO x It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com