Method for preparing emulsified residual oil by using cyclohexanone wastewater

A technology for cyclohexanone wastewater and residual oil, which is applied in chemical instruments and methods, natural water treatment, multi-stage water/sewage treatment, etc. and social benefits, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

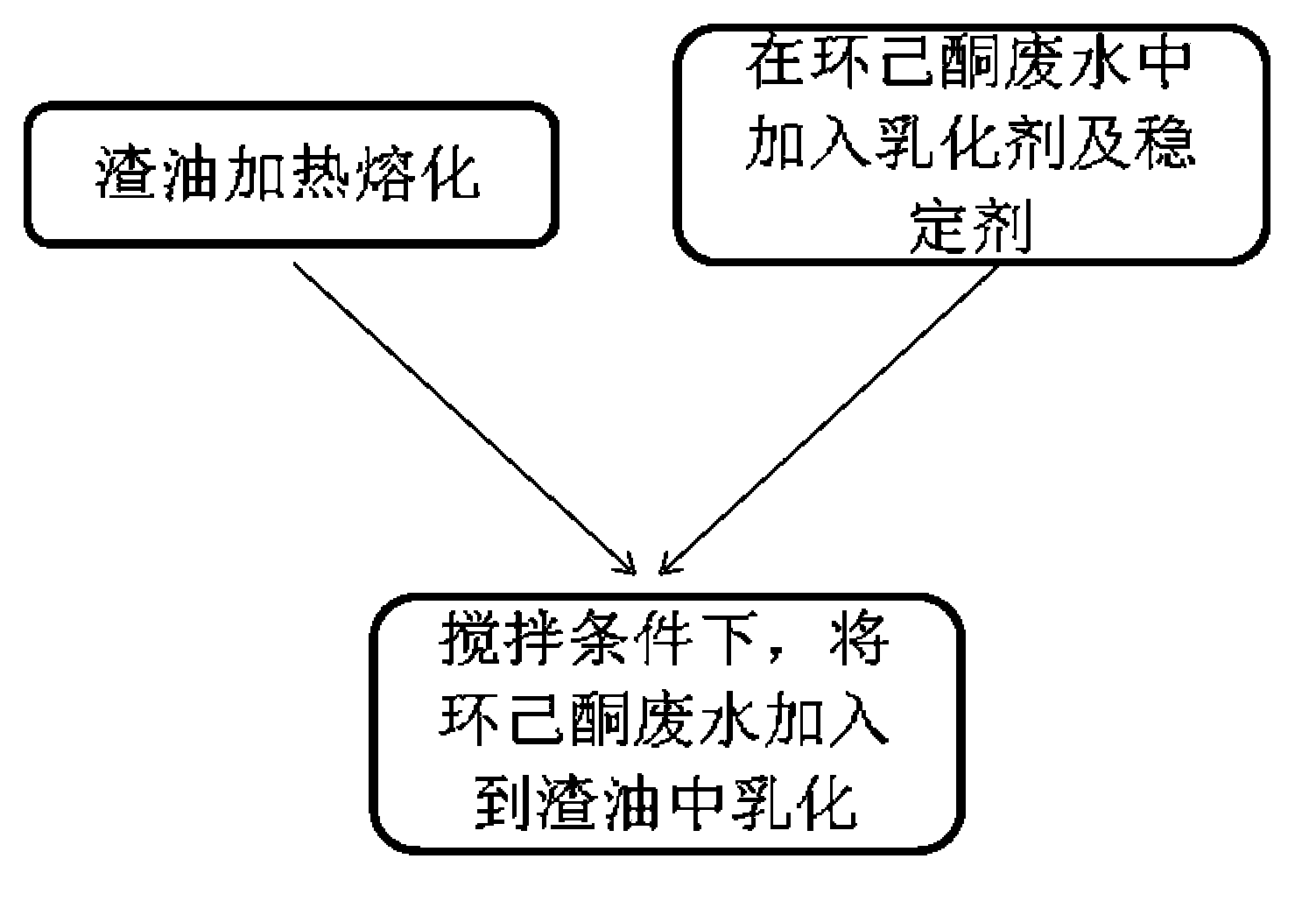

[0035] Example 1: Take 20 g of cyclohexanone wastewater (pH 9, COD 5000 mg / L) into a three-necked flask, add 0.3 g of alkylphenol polyoxyethylene ether (OP-10) and 0.005 g of polyacrylamide (1630s) Obtain the aqueous solution of emulsifier, stir to dissolve, heat to 80 o C insulation. Weigh 80g of residual oil and heat to 120 o C to melt, then at 80 o Keep warm at C. Under the condition of high-speed stirring, the aqueous solution of the emulsifier is evenly added to the residual oil, and stirred for 15 minutes to obtain the emulsified residual oil. The prepared emulsified residue has a viscosity of 600mPa·S and can be stored stably for more than 3 days at room temperature. For the preparation process, see figure 1 .

Embodiment 2

[0036] Example 2: Take 30 g of cyclohexanone wastewater (pH 10, COD 8000 mg / L) into a three-necked bottle, add 0.1 g of alkylphenol polyoxyethylene ether (OP-10), 0.2 g of dodecyl Sodium sulfate and 0.05g of hydroxymethyl cellulose to obtain an aqueous solution of an emulsifier, stir to dissolve, and heat to 75 o C insulation. Weigh 70g of residual oil and heat to 120 o C to melt, then at 75 o Keep warm at C. Under the condition of high-speed stirring, the aqueous solution of the emulsifier is evenly added to the residual oil, and the emulsified residual oil can be obtained by stirring for 5 minutes. The prepared emulsified residue has a viscosity of 800mPa·S and can be stored stably for more than 3 days at room temperature.

Embodiment 3

[0037] Example 3: Take 10 g of cyclohexanone wastewater (pH 11, COD 20000 mg / L) into a three-necked bottle, add 5 g of alkylphenol polyoxyethylene ether (OP-10) and 0.05 g of polyvinyl alcohol Obtain an aqueous solution of emulsifier, stir to dissolve, heat to 70 o C insulation. Weigh 90g of residual oil and heat to 130 o C to melt, then at 70 o Keep warm at C. Under the condition of high-speed stirring, the aqueous solution of the emulsifier is evenly added to the residual oil, and the emulsified residual oil can be obtained by stirring for 10 minutes. The prepared emulsified residue has a viscosity of 700mPa·S and can be stored stably for more than 3 days at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com