Jigging machine with entered material pretreatment function

A jig and pretreatment technology, applied in the field of jig, can solve the problems of installation difficulty, increase the loss of elevation, increase the floor area of the workshop, etc., so as to reduce the equipment failure rate, reduce the floor space, and reduce the number of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

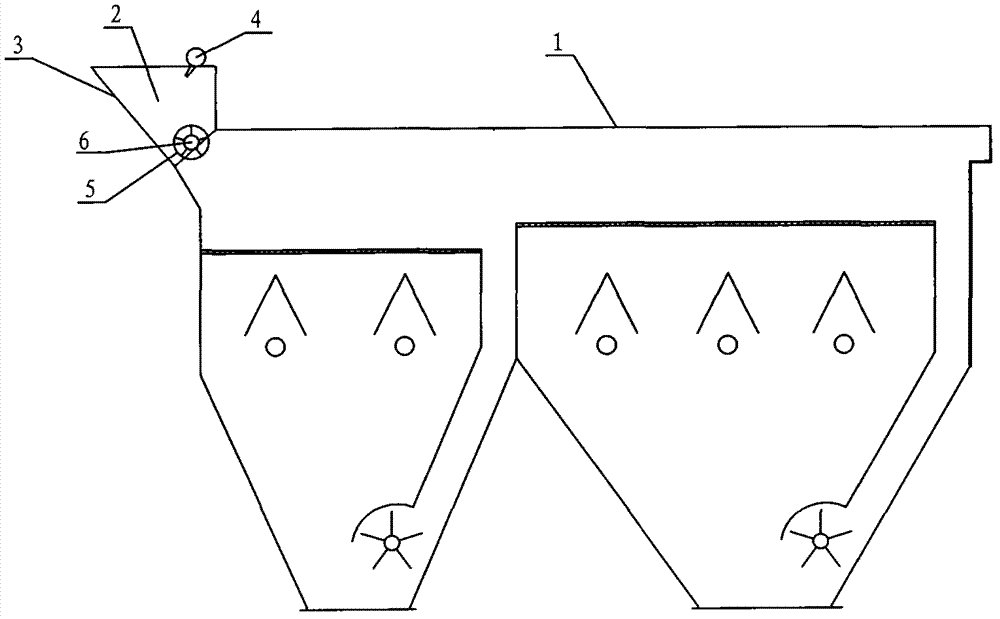

[0018] A jigging machine with feed pretreatment function according to the present invention can provide various types of jiggers with feed pretreatment function according to different jiggers. The machine makes further explanations:

[0019] figure 1 Among them, a two-stage air pulsation jig with feed pretreatment function, which includes a two-stage air pulsation jig body 1 and a coal distributing and wetting device 2 . Wherein said two-stage air pulsation jig machine body 1 is prior art, and its related parts, shape, structure, materials used, effect, function etc. are existing conventional technology and method, and difference is in its A coal distributing and wetting device 2 is combinedly designed on the material inlet, and a material feeding pretreatment function is added on the basis of the existing functions of the two-stage air pulsation jig. The coal distributing and wetting device 2 is composed of a hopper 3 , a water spraying device 4 and a coal distributing stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com