Gluing machine cleaning device capable of shoveling gel and automatically cleaning

A technology for automatic cleaning and cleaning devices, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of affecting the service life of liquid storage tanks, reducing the use of water resources, and reducing the diameter of liquid storage tanks, etc. problems, achieve the effect of reducing the use of water resources, improving mixing efficiency and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

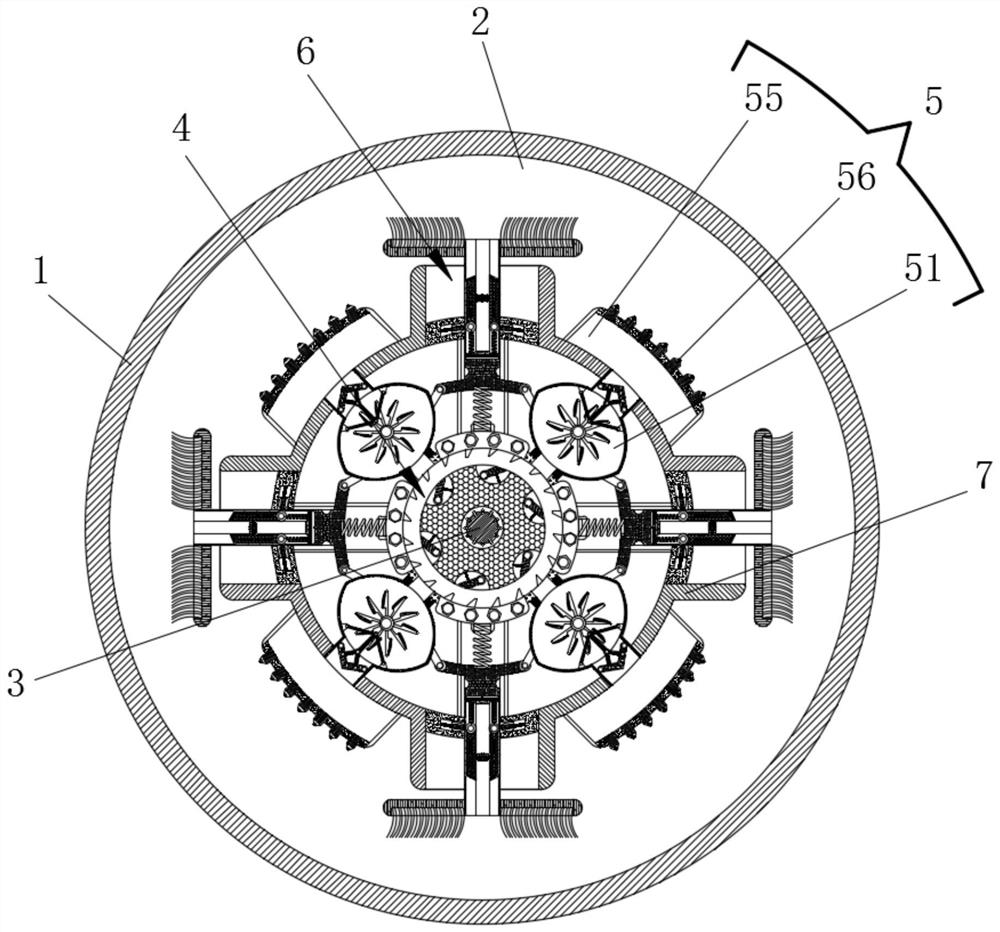

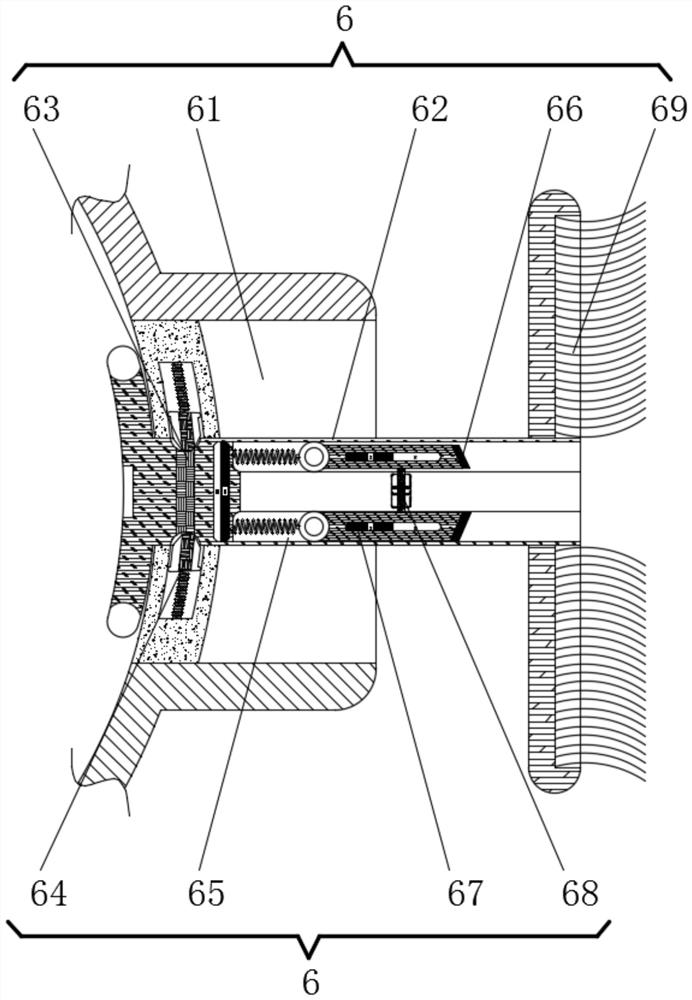

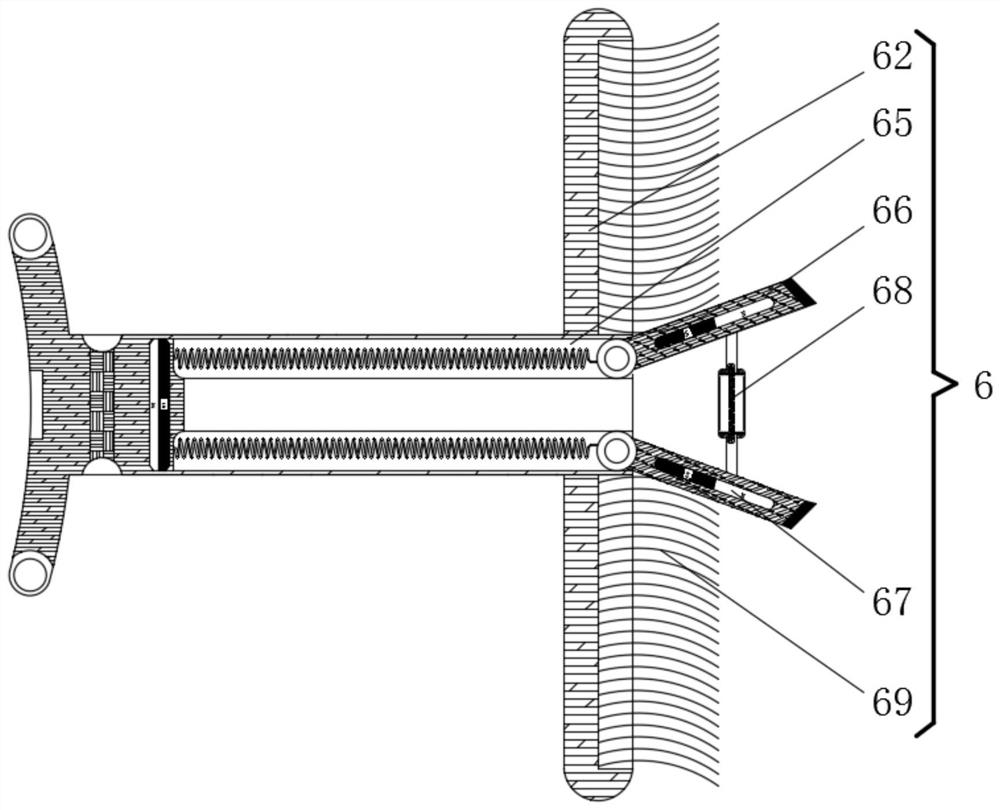

[0028] see Figure 1-4 , a glue applicator cleaning device that removes gel and automatically cleans, the cleaning mechanism 6 includes a chute 61, the inside of the chute 61 is slidably connected with a sliding frame 62, and the inside of the sliding frame 62 is fixedly connected with a metal strip 63, the chute 61 is slidably connected with a movable block 64 near the side of the sliding frame 62, and the inside of the sliding frame 62 is provided with a slide rail 65, and the inside of the slide rail 65 is slidingly connected with a spatula 66, and the interior of the spatula 66 is fixedly connected with a magnetic block 67. The outer surface of knife 66 is fixedly connected with spring bar 68, and the end of sliding frame 62 is fixedly connected with cleaning block 69, and the inside of chute 61 is fixedly connected with support plate, and the center of circle of support plate is slidably connected with sliding frame 62, and supports The interior of the plate is slidingly ...

Embodiment 2

[0030] see figure 1 , 4And 5, a glue applicator cleaning device that removes the gel and automatically cleans, including a cleaning mechanism 5, the cleaning mechanism 5 includes an elastic chamber 51, the inside of the elastic chamber 51 is fixedly connected with a liquid pump 52, and the inside of the elastic chamber 51 is connected to the rotatable There is a movable connecting rod 53, and the end of the movable connecting rod 53 away from the elastic cavity 51 is rotatably connected with a baffle 54, and the outer side of the elastic cavity 51 is fixedly connected with a liquid tank 55, and the side wall of the liquid tank 55 is fixedly connected with a nozzle 56, and the elastic cavity 51 It is a space-tight cavity made of rubber, and the elastic chamber 51 and the liquid chamber 55 communicate with each other. The baffle 54 is rotatably connected in the connecting pipe between the elastic chamber 51 and the liquid chamber 55, and the diameter of the baffle 54 is the same...

Embodiment 3

[0032] see Figure 1-5 , a glue applicator cleaning device that removes gel and automatically cleans, including a cleaning mechanism 5, the cleaning mechanism 5 includes an elastic chamber 51, the inside of the elastic chamber 51 is fixedly connected with a liquid pump 52, and the inside of the elastic chamber 51 is rotatably connected with a movable The connecting rod 53, the end of the movable connecting rod 53 away from the elastic cavity 51 is rotatably connected with a baffle 54, the outer side of the elastic cavity 51 is fixedly connected with a liquid tank 55, the side wall of the liquid tank 55 is fixedly connected with a nozzle 56, and the elastic cavity 51 is made of rubber The gap of the material seals the cavity, and the elastic chamber 51 communicates with the liquid chamber 55, and the baffle plate 54 is rotatably connected in the connecting pipe between the elastic chamber 51 and the liquid chamber 55, and the diameter of the baffle plate 54 is the same as that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com