Steel conduit inner wall anticorrosion device and method

A technology of anti-corrosion device and steel conduit, which is applied to spray devices, liquid spray devices, etc., can solve the problems of difficult to control anti-corrosion quality, uneven coating, environmental hazards, etc., and achieves good anti-corrosion treatment effect, smooth coating, The effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

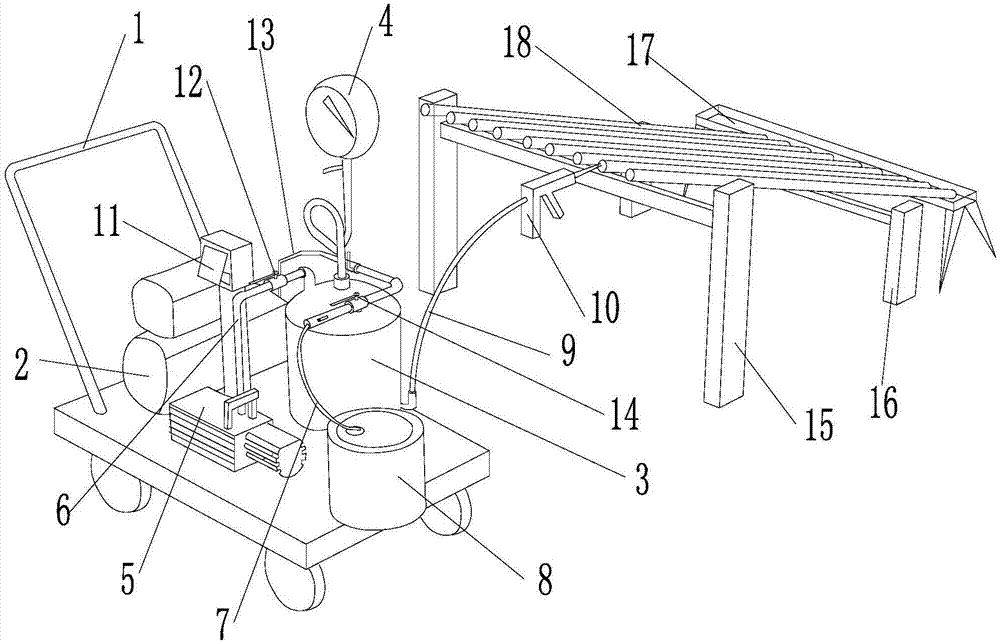

[0037] Such as figure 1 As shown, the anti-corrosion device for the inner wall of the steel conduit according to the present invention includes a support for placing the steel conduit 18 obliquely, a high-pressure spray gun 10 for spraying anti-corrosion paint on the inner wall of the steel conduit 18, and an anti-corrosion actuator for the high-pressure spray gun 10 providing the anti-corrosion paint. The anti-corrosion executive mechanism includes a mobile platform 1 and a pressure vessel 3 arranged on the mobile platform 1, a vacuum pump 5 for evacuating the pressure vessel 3, a paint mixing bucket 8 for delivering the anti-corrosion paint to the pressure vessel 3, and a pressure vessel 3 to the pressure vessel 3. The supercharging device 2 for supercharging and the control cabinet 11 for controlling the spraying of the anticorrosion paint, the control cabinet 11 is integrated with a controller, and the top of the pressure vessel 3 is equipped with a pressure gauge 4 for mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com