A kind of method for treating waste lye of cyclohexanone plant

A technology of cyclohexanone and waste lye, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of resource utilization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

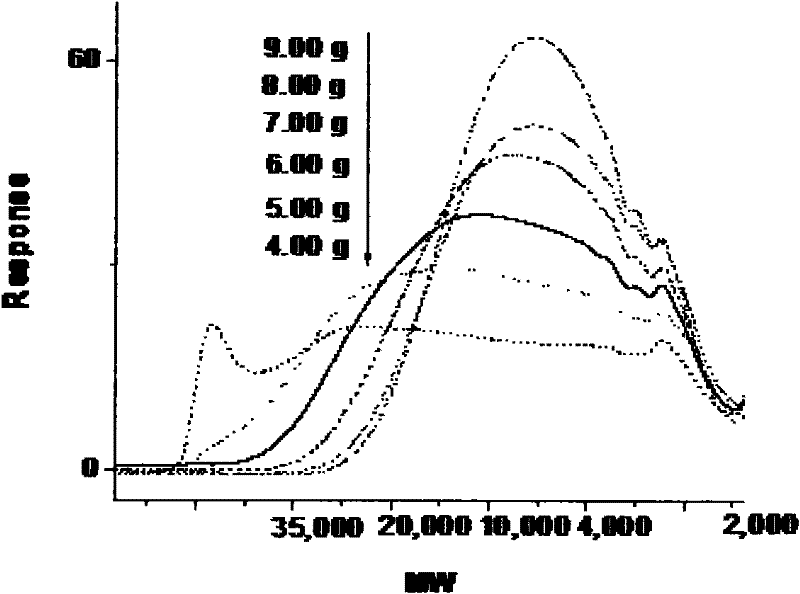

[0070] Take 100mL of cyclohexanone waste lye, add 4~9g of sodium sulfite to it, dissolve and heat to 40°C, add 10mL of acetone, react for 30min, then heat up to 80°C, add 20mL of formaldehyde solution, continue to react for 1h, keep Add 950 parts of waste lye of cyclohexanone plant at high temperature, and react for 1 hour to make the composite coal-water slurry additive with an effective concentration of 0.5%; naturally cool to room temperature, and its different molecular weight distribution curves are as follows: figure 1 As shown, the molecular weight of the product decreases significantly with the increase of the amount of sulfonating agent. Wherein the occurrence of sodium sulfite being 4g causes the hydrophilicity of the product to decrease due to insufficient sulfonation, forming a light yellow insoluble matter. The non-sticky coal is ground by a ball mill to obtain coal powder with a mass percentage of particles with an average particle size of less than 75 μm greater...

Embodiment 2

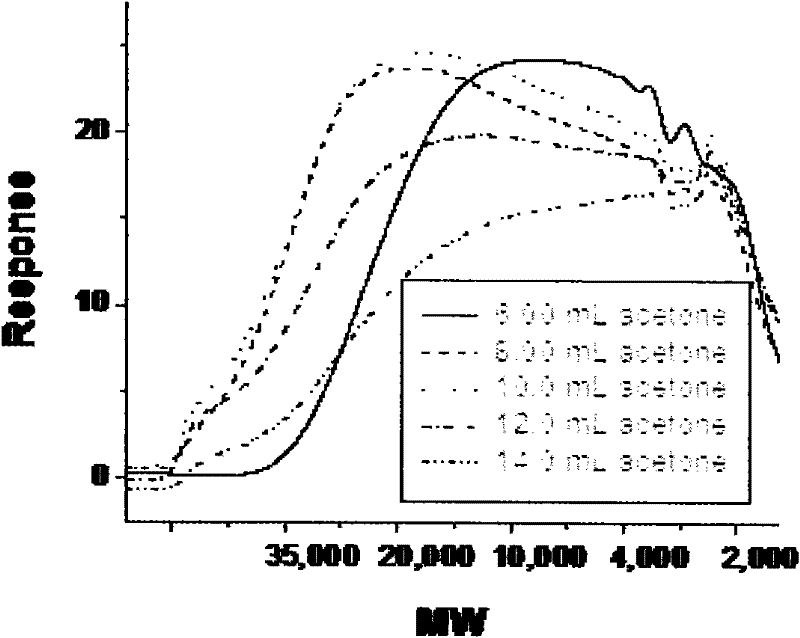

[0072] Take 100mL of cyclohexanone waste lye, add 5g of sodium sulfite to it, dissolve and heat to 40°C, add 6-14mL of acetone, react for 30min and then heat up to 80°C, add 20mL of formaldehyde solution, continue to react for 1h, keep Add 950 parts of waste lye of cyclohexanone plant at high temperature, and react for 1 hour to make the composite coal-water slurry additive with an effective concentration of 0.5%; naturally cool to room temperature, and its different molecular weight distribution curves are as follows: figure 2 As shown, with the increase of the amount of acetone, the molecular weight of the product first increases and then decreases. When the amount of acetone is small, the molecular weight may be small due to excessive sulfonation, and the initial reaction rate is low; and when the amount of acetone is large, the reaction rate is too fast, and the large ketone-aldehyde ratio is likely to cause a reduction in the degree of polymerization, so that Molecular w...

Embodiment 3

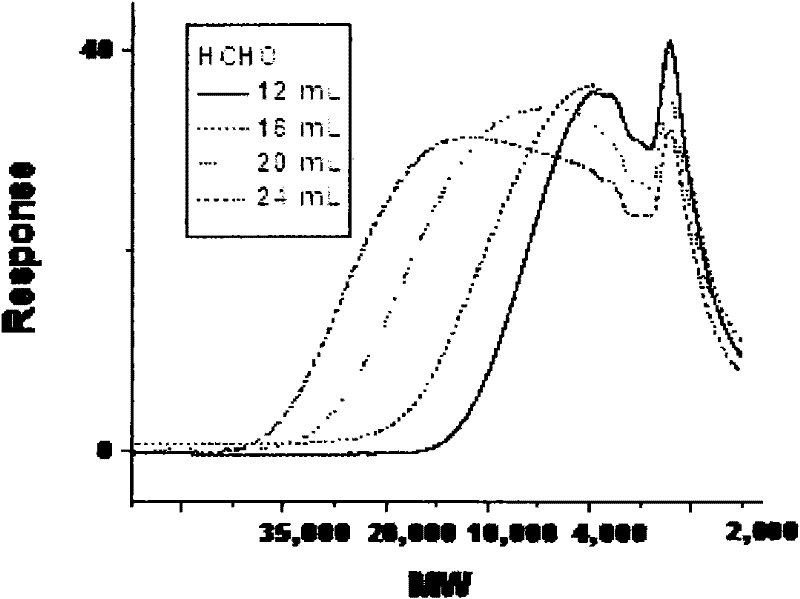

[0074] Take 100mL of cyclohexanone waste lye, add 5g of sodium sulfite to it, dissolve and heat to 40°C, add 10mL of acetone, react for 30min and then heat up to 80°C, add 12-24mL of formaldehyde solution, continue the reaction for 1h, keep Add 950 parts of waste lye of cyclohexanone plant at high temperature, and react for 1 hour to make the composite coal-water slurry additive with an effective concentration of 0.5%; naturally cool to room temperature, and its different molecular weight distribution curves are as follows: image 3As shown, with the increase of the amount of formaldehyde, the molecular weight distribution of the product has a greater impact. The non-sticky coal is ground by a ball mill to obtain coal powder with a mass percentage of particles with an average particle size of less than 75 μm greater than 80%. The composite coal-water slurry additive obtained by reacting 20ml of formaldehyde and the non-sticky coal powder are in a mass ratio of 38:62 After prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com