Sealing capsule and application thereof in coal mine

A technology for sealing capsules and capsules, which is used in mining equipment, mining equipment, earth-moving drilling and other directions, can solve the problems of poor sealing effect, short service life of wooden walls, heavy weight and other problems, and achieves low loss rate, easy management, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

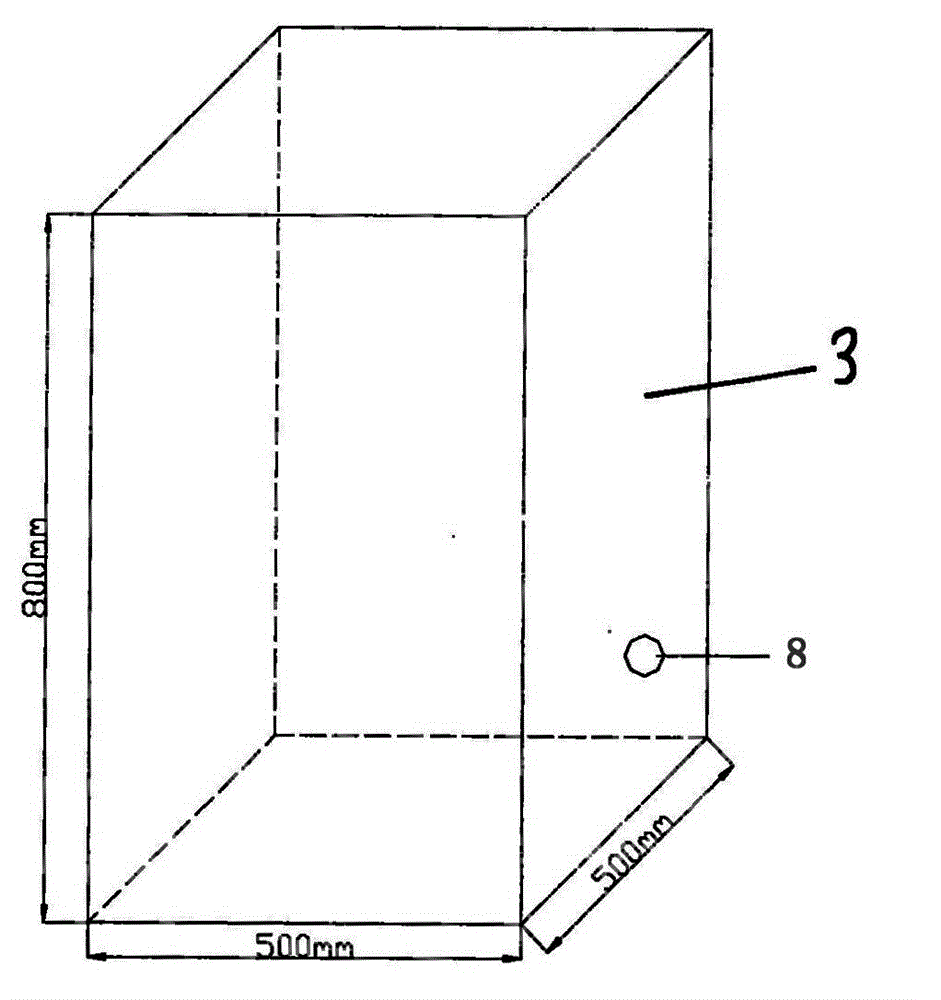

[0020] Such as figure 1 As shown, the sealed capsule 3 of the present invention is a rectangular cubic airbag made of antistatic and flame-retardant rubber material, and an inflation and deflation valve 8 is arranged on the rectangular cubic airbag.

[0021] More specifically, the sealed capsule is processed into a cuboid airbag according to the size of 500mm×500mm×800mm, and an air valve for automobile tires is arranged on the lower part of one side of the cuboid.

[0022] The inflation method of the sealed capsule is as follows: ground pressure inflation can be inflated with an ordinary air cylinder, and the working surface air pressure self-rescue system air duct is used in the underground, and is connected with a flexible pipe through a variable diameter joint.

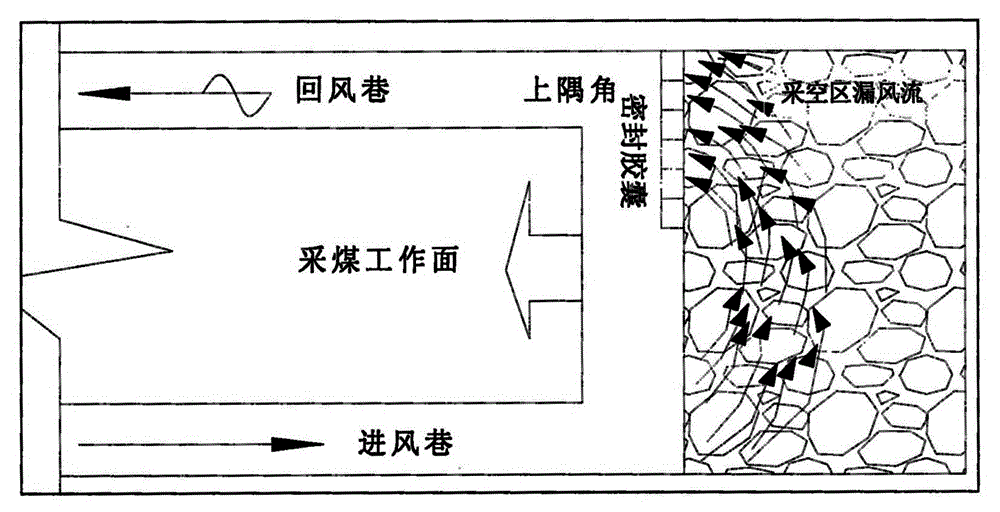

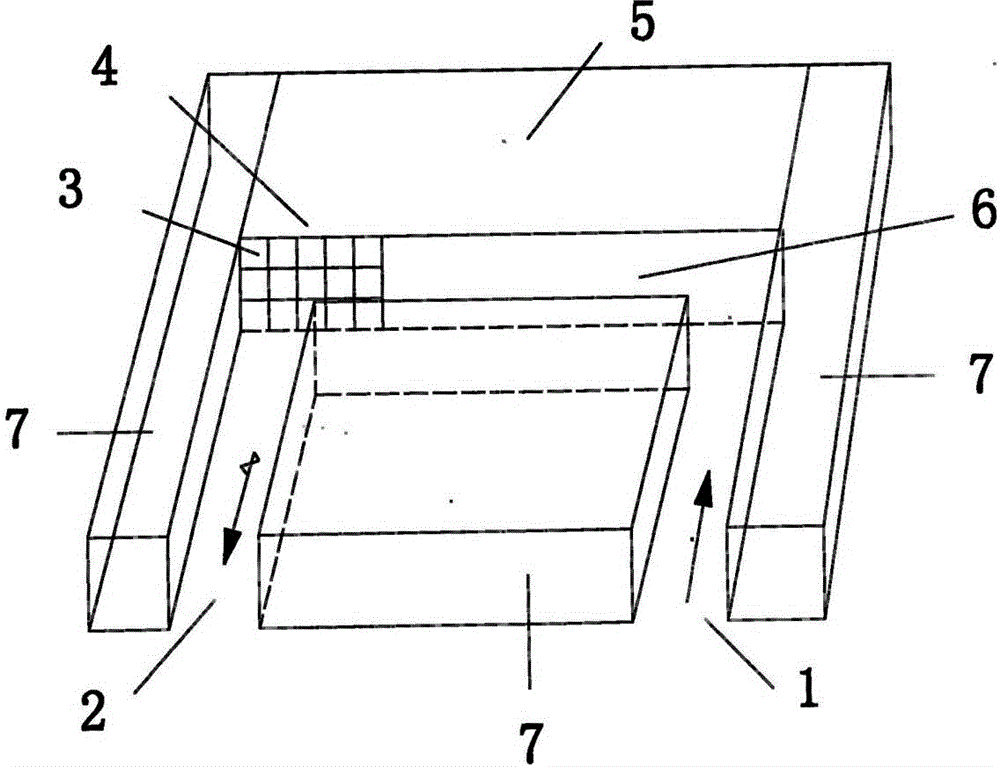

[0023] Such as figure 2 , image 3 Shown, the application method of sealed capsule of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com