Coal gas waste gas, waste slag and waste ash comprehensive utilization process and apparatus

A coal-to-gas and waste residue technology, which is used in the manufacture of combustible gas, sustainable manufacturing/processing, and the petroleum industry. The effect of saving energy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

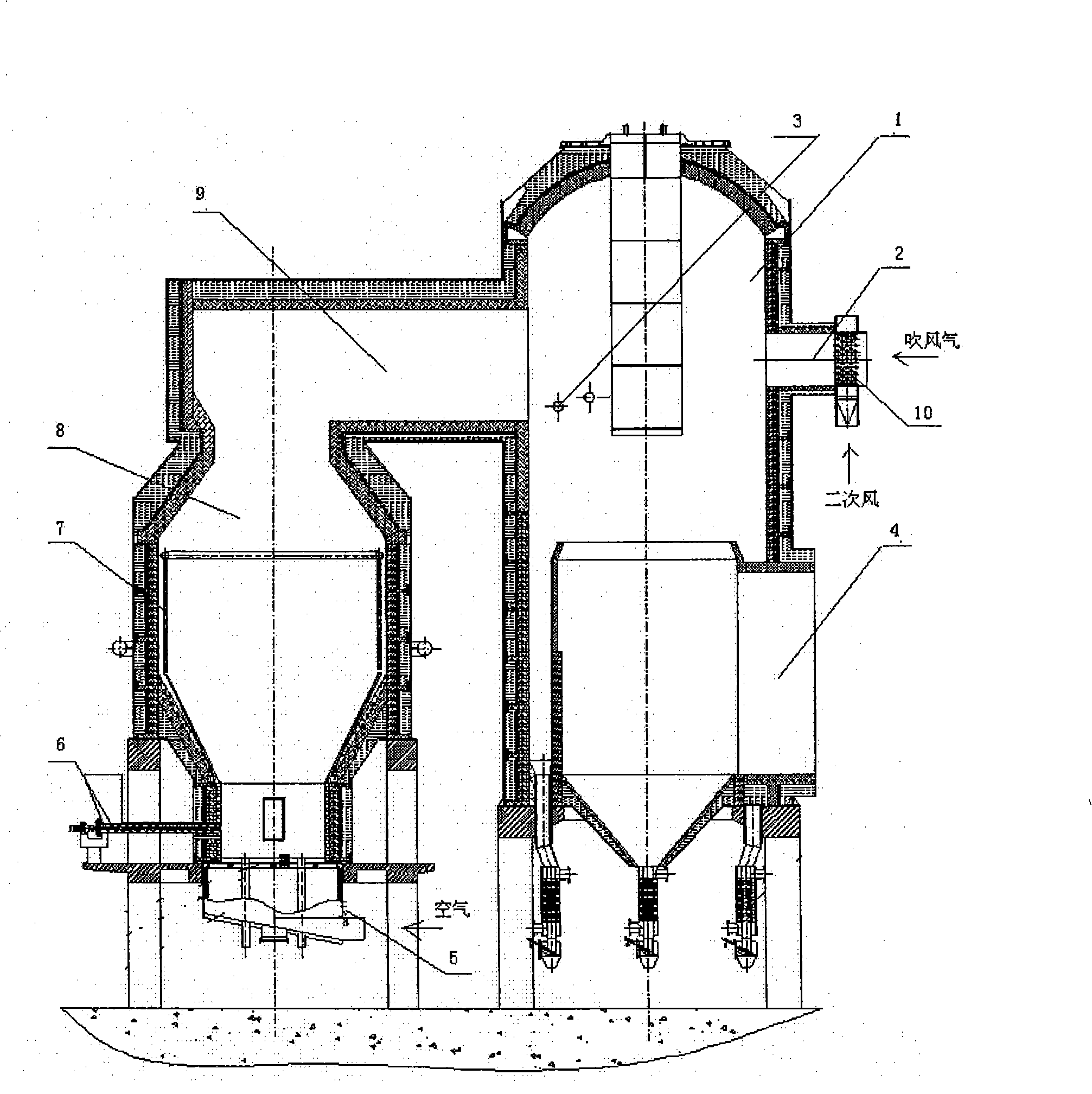

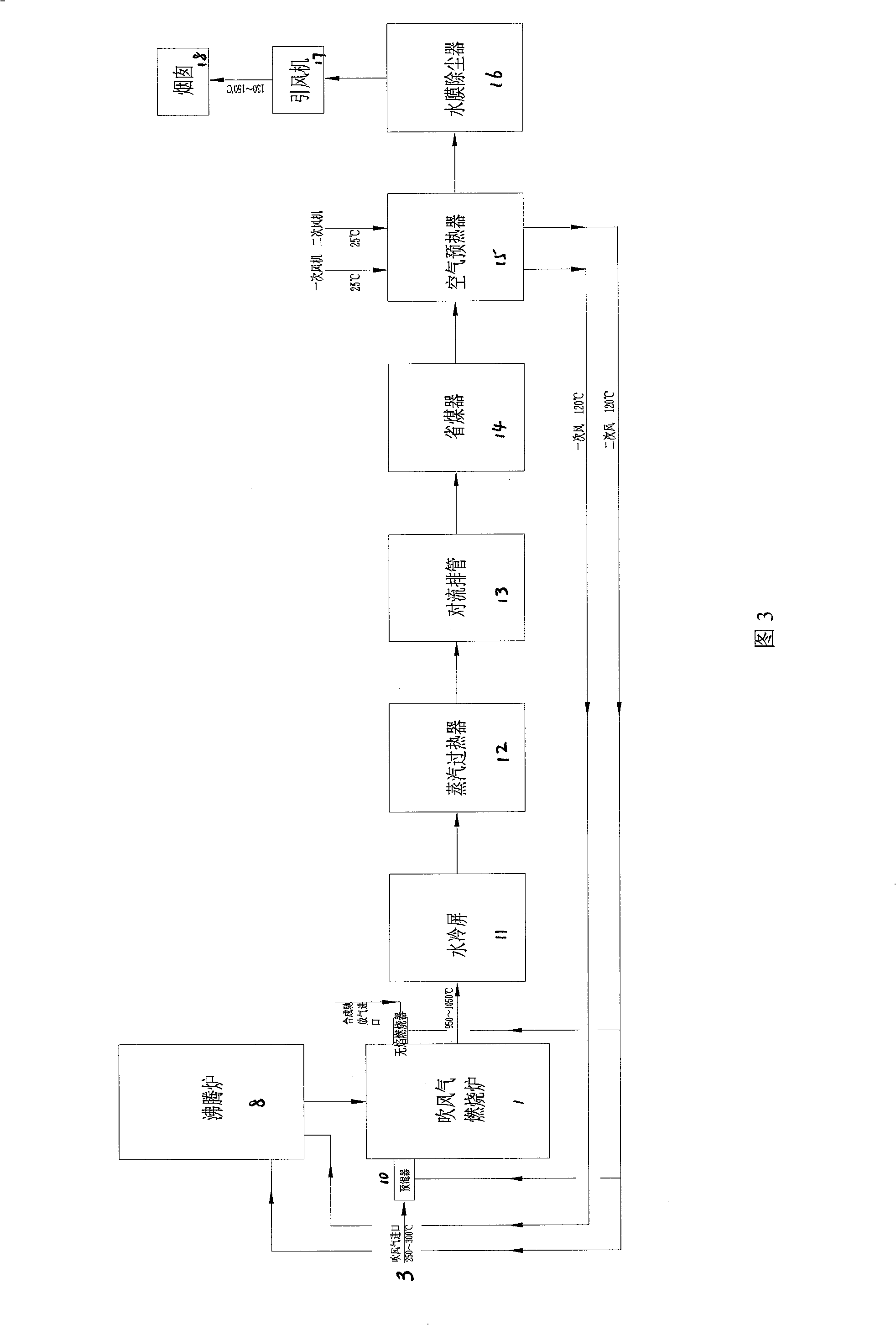

[0030] Embodiment one: see figure 2 As shown in Figure 3, the comprehensive utilization process of waste gas, waste residue and ash from coal gasification is to combine fluidized bed furnace 8 with coal gas blowing waste heat recovery system, and fluidized bed furnace 8 uses the waste residue and waste ash after coal gasification as fuel for secondary combustion , generate high-temperature flue gas to ignite the blowing gas in the blowing gas burner 1, and the flue gas after the burning of the blowing gas passes through the waste heat recovery system and is discharged into the atmosphere by the chimney.

[0031] The specific process steps are as follows:

[0032] a. The gas-making slag and coal ash are sent to the lower part of the fluidized fluidized furnace 8 by the spiral coal feeder 6, and the primary air preheated to 120±15°C by the air preheater 15 is used for combustion reaction;

[0033] b. The high-temperature flue gas produced by the fluidized fluidized furnace 8 e...

Embodiment 2

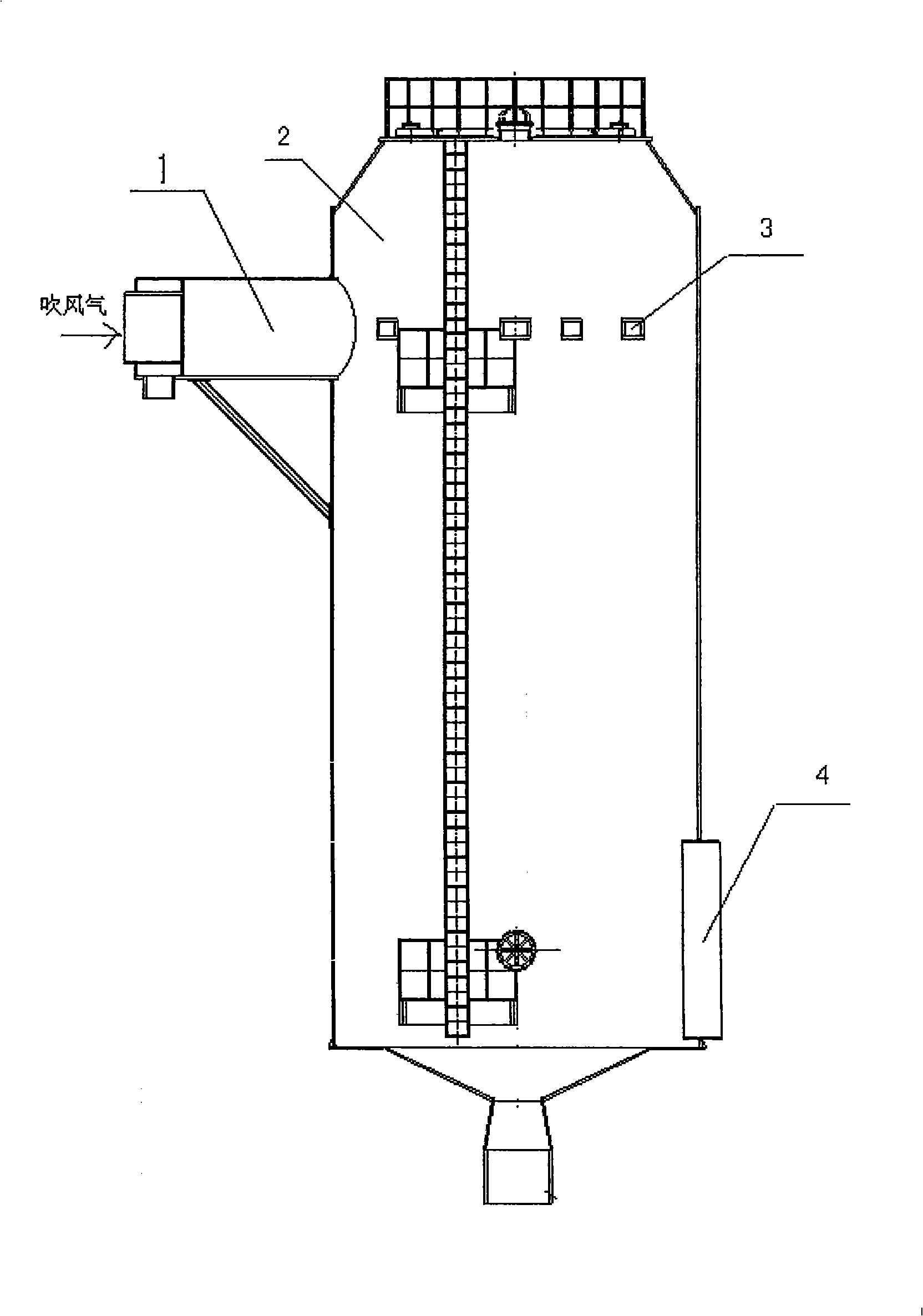

[0037] Embodiment two: see figure 2 As shown in Fig. 4, the waste gas, waste residue and ash comprehensive utilization device of this coal-to-gas system is connected to the water cooling screen 11, the steam superheater 12, the convection exhaust pipe 13 of the waste heat boiler, and the economizer in sequence from the flue gas outlet 4 of the blowing gas combustion furnace 1 14. After the air preheater 15 and the water film deduster 16, it passes through the induced draft fan 17, and finally connects to the chimney 18 to form a blowing air waste heat recovery system, which is characterized in that there is a fluidized fluidized furnace 8 and the blowing air combustion furnace 1 connection, the high-temperature flue gas outlet of the fluidized fluidized furnace 8 communicates with the furnace upper chamber of the blowing gas combustion furnace.

[0038] The above-mentioned fluidized fluidized furnace 8 is combined with the blowing gas combustion furnace to form a composite mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com