Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

A technology for coal gasification wastewater and stripping, which is applied in chemical instruments and methods, separation methods, degassed water/sewage treatment, etc., can solve problems such as affecting the efficiency and normal operation of equipment, inability to reduce pollution loads, and unbearable economy. Achieve the effect of improving the extraction effect, saving the amount of caustic soda, and reducing the processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

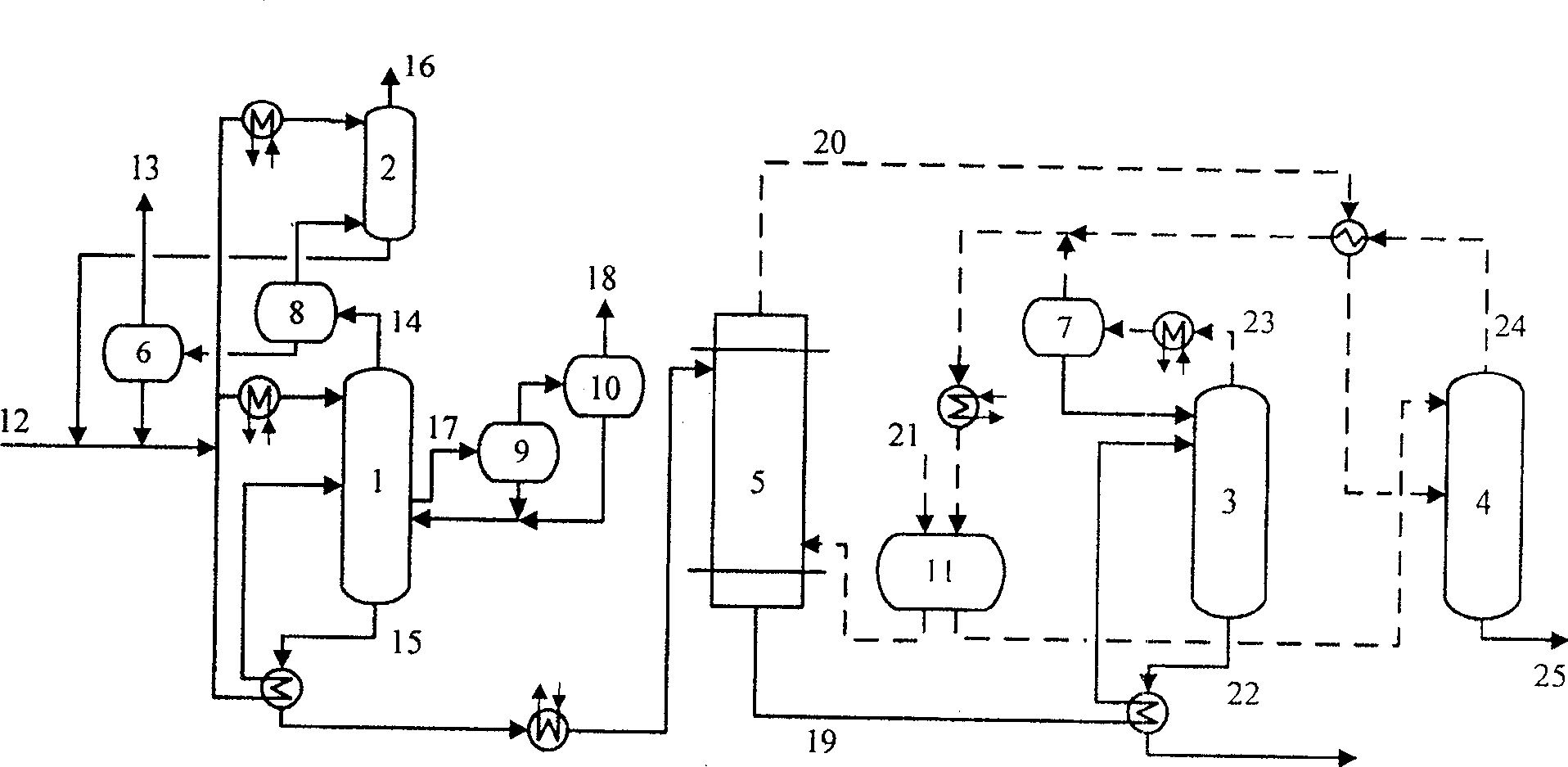

[0030] The flow rate is 88 tons / hour, and the total phenol content is about 6400mg·l -1 (Volatile phenol about 3200mg l -1 , fatty acid about 3000mg·l -1 ); the total ammonia content is 7800mg l -1 , CO 2 About 4200mg·l -1 , oil content 350mg·l -1 , COD Cr The value is about 25000mg·l -1 , with a pH value of 10 and a water temperature of 80°C, the waste water to be treated is figure 1 process as shown. The parameters such as the number of stages, pressure and temperature of each tower are as follows:

[0031] Theoretical stages of the oleic acid gas and ammonia stripping tower are 25, the upper part of the feed inlet is bulk packing, the lower part of the feed inlet is a slanted hole tray, the temperature at the top of the tower is 60°C, the pressure is 0.32MPa, the temperature at the bottom of the tower is 138°C, and the pressure is 0.34 MPa. The side line production temperature is 133°C, the pressure is 0.33MPa, and the washing water volume of the acid gas scrubber...

Embodiment 2

[0036] The flow rate is 60 tons / hour, and the total phenol content is about 5500mg·l -1 (Volatile phenol about 3000mg·l -1 , the fatty acid is about 3120mg·l -1 ), total ammonia 5900mg·l -1 , CO 2 About 6000mg·l -1 , oil content 400mg·l -1 , COD Cr The value is about 23000mg·l -1 , the pH value is 9.5, and the wastewater to be treated at a water temperature of 80°C is figure 1 process as shown. The parameters such as the number of stages, pressure and temperature of each tower are as follows:

[0037] The temperature at the top of the oleic acid gas and ammonia stripping tower is 55°C, the pressure is 0.4MPa, the temperature at the bottom of the tower is 148°C, and the pressure is 0.43MPa. The side line production temperature is 141°C and the pressure is 0.42MPa.

[0038] The height of the packing layer of the extraction tower is 14m, diisopropyl ether is used as the extraction agent, the pH is adjusted by adding acid before extraction, the solvent ratio is 1:6, the ...

Embodiment 3

[0043] The flow rate is 100 tons / hour, and the total phenol content is about 5300mg·l -1 (Volatile phenol about 2600mg·l -1 , fatty acid about 2800mg·l -1 ), total ammonia 6000mg·l -1 , CO 2 About 9000mg·l -1 , oil content 400mg·l -1 , COD Cr The value is about 22000mg·l -1 , with a pH value of 10 and a water temperature of 80°C, the waste water to be treated is figure 1 process as shown. The parameters such as the number of stages, pressure and temperature of each tower are as follows:

[0044] The height of the packing layer of the extraction tower is 10m, the extraction agent is methyl isobutyl ketone, the pH is adjusted by adding acid before extraction, and the solvent ratio is 1:6. The rest of the conditions are the same as Example 1.

[0045] The total phenol content in the treated wastewater is 320mg·l -1 , the total ammonia content is less than 80mg·l -1 , COD Cr About 3300mg·l -1 , the extractant is less than 10mg·l -1 , after biochemical treatment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com