Method and system for decarburization through complete combustion of boiler as well as desulfurization, denitration and dust removal of exhaust gas

A technology of complete combustion, desulfurization and denitrification, applied in combustion methods, chemical instruments and methods, transportation of non-flammable liquids/gases, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

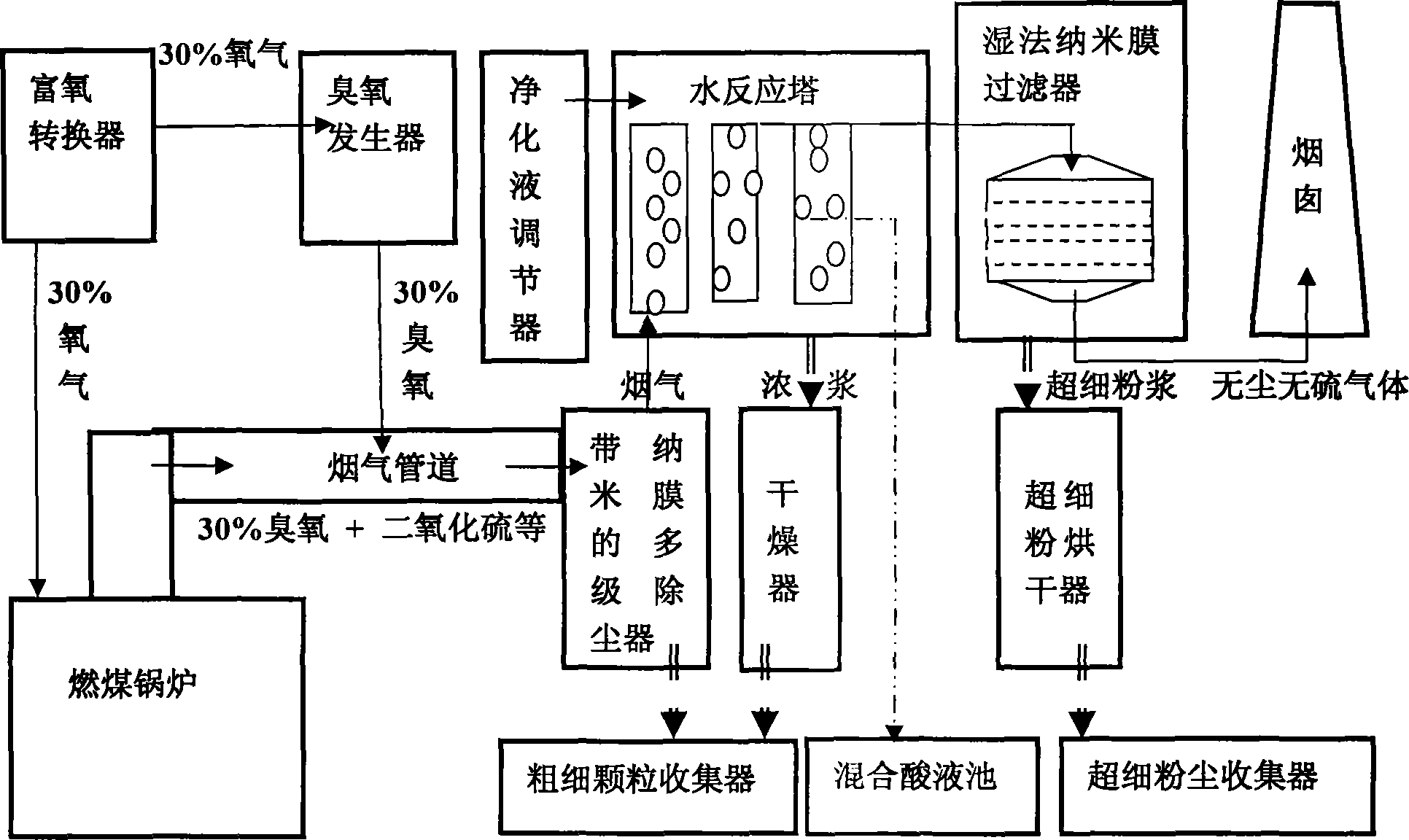

[0036] Embodiment 1. The method and system used for boiler complete combustion decarbonization and flue gas desulfurization, denitrification and dust removal

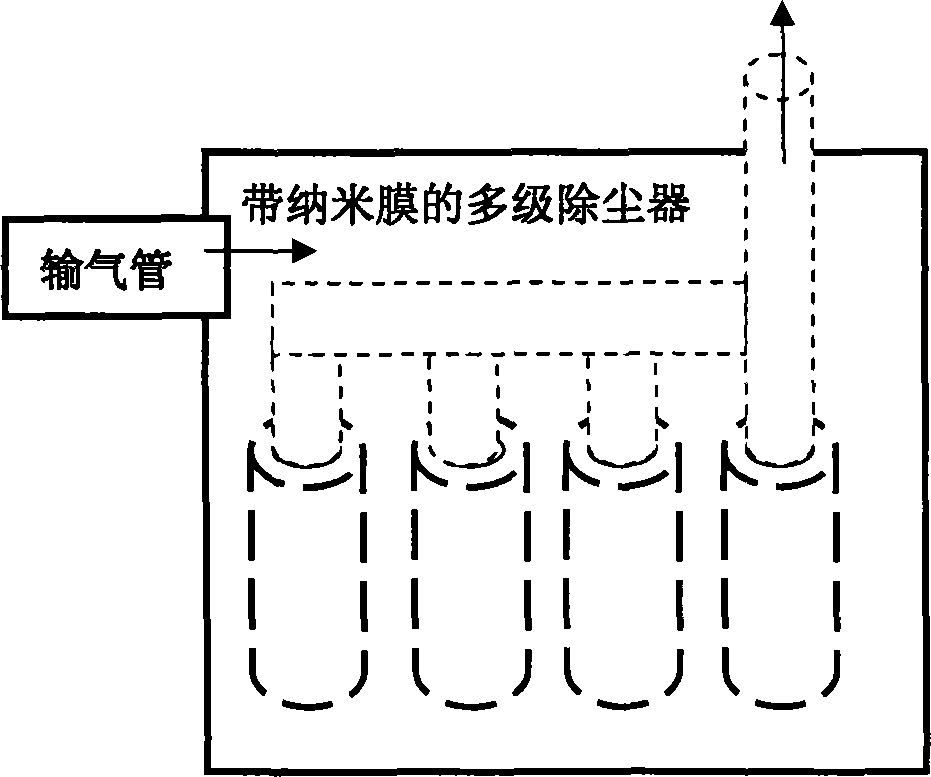

[0037] like figure 1 ,

[0038] (1) The method of boiler complete combustion decarbonization and flue gas desulfurization, denitrification and dust removal

[0039] 1. The method of complete combustion and decarbonization of the boiler: fill the combustion chamber of the boiler with oxygen-enriched gas. The oxygen-enriched gas is an oxygen-enriched gas with a weight ratio of 30% oxygen, so that the coal can be fully burned and the amount of incomplete combustion can be reduced. emissions, that is, oxygen-enriched decarbonization.

[0040] 2. The method of flue gas desulfurization and denitrification: add ozone-rich gas into the 500-600°C high-temperature flue gas discharge pipe discharged from the boiler. The ozone-rich gas is a gas containing 30% ozone by weight. After fully mixing and acting in the discharge pipe,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com