Method and device for treatment of air containing viscous paint particles

A technology of air treatment and paint, which is applied in the field of environmental engineering, can solve problems such as failure to meet pre-treatment requirements, paint particles sticking to equipment, and inability to operate stably, achieving good results, stable operation of equipment, and avoiding blockage of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

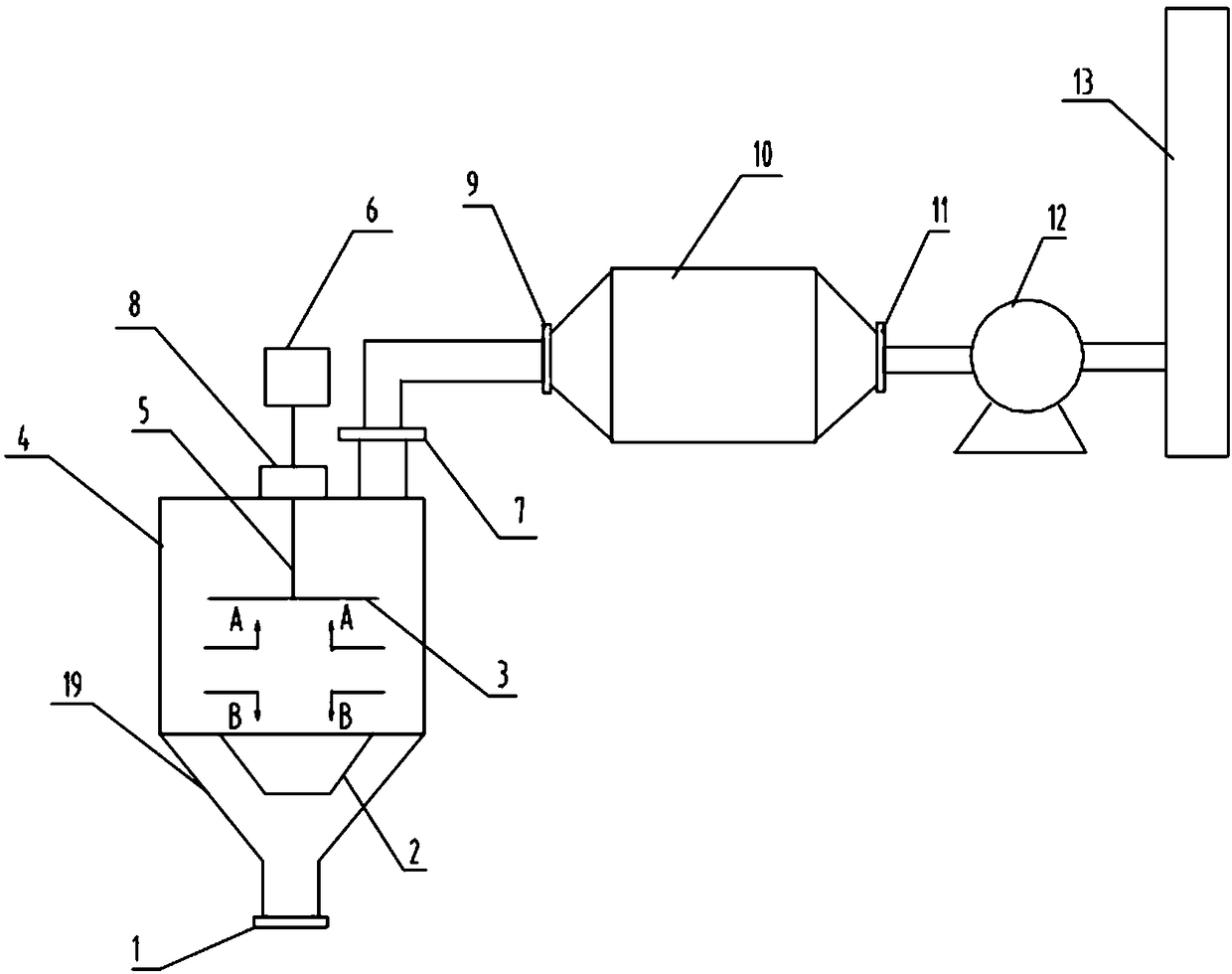

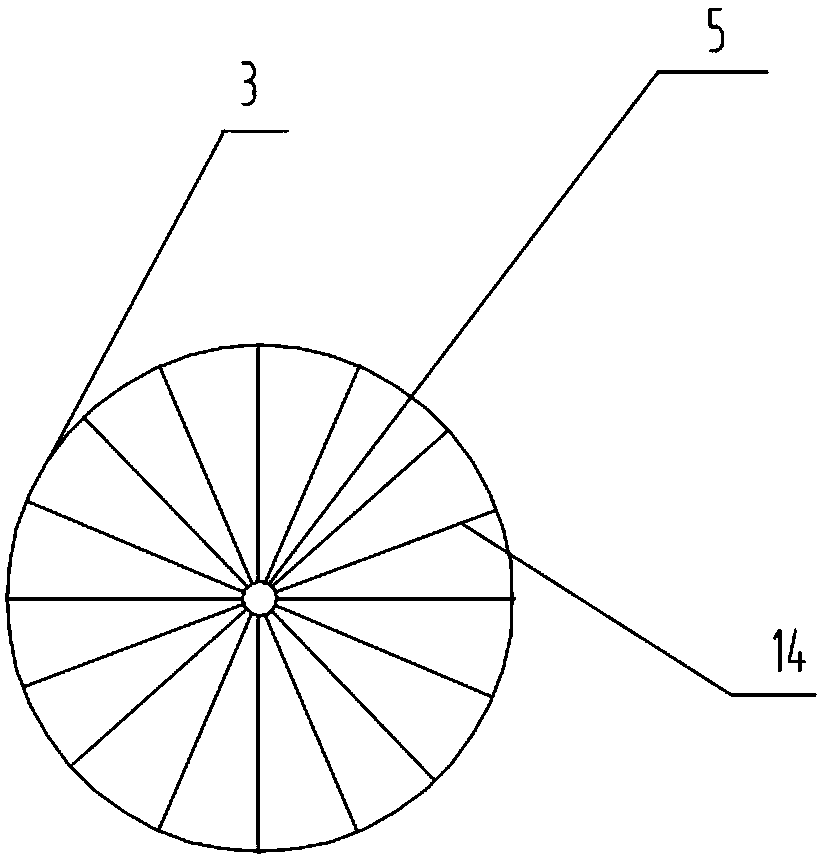

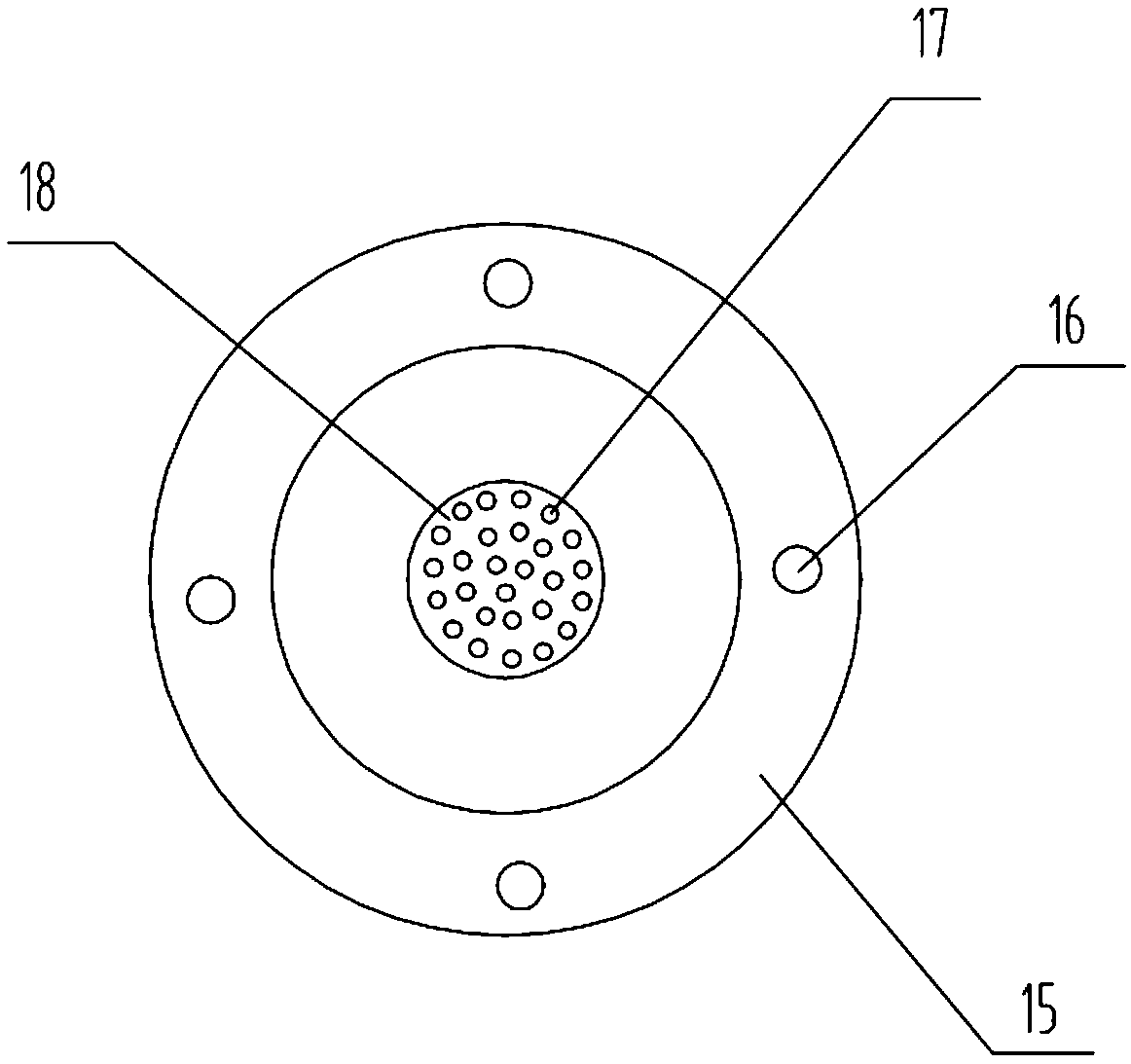

[0024] Connect a cover device, comprise paint purifier (4), active carbon adsorber (10), blower fan (12), chimney (13), the bottom and top of described paint purifier (4) are respectively provided with air guiding cover (19 ) and the paint purifier outlet (7), the exhaust gas inlet (1) is arranged at the bottom of the air guide cover (19), and the filter device (2) is arranged in the air guide cover (19), and the filter device (2 ) includes a screen cloth (18) with several small holes (17) and a disc (15) with large holes (16), and a centrifugal rotating disc (3) is set in the paint purifier (4), and the The centrifugal turntables (3) are connected by stirring shafts (5), and the centrifugal turntables (3) are respectively made of several intercepting blades (14), and the stirring shafts (5) protrude from the top of the paint purifier (4) Link to each other with motor (6) through dynamic sealing sleeve (8), described paint purifier outlet (7) is connected with the activated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com