Method for preparing lignin amine from cyclohexanone wastewater

A technology for cyclohexanone wastewater and wastewater, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Problems, the effect of realizing reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

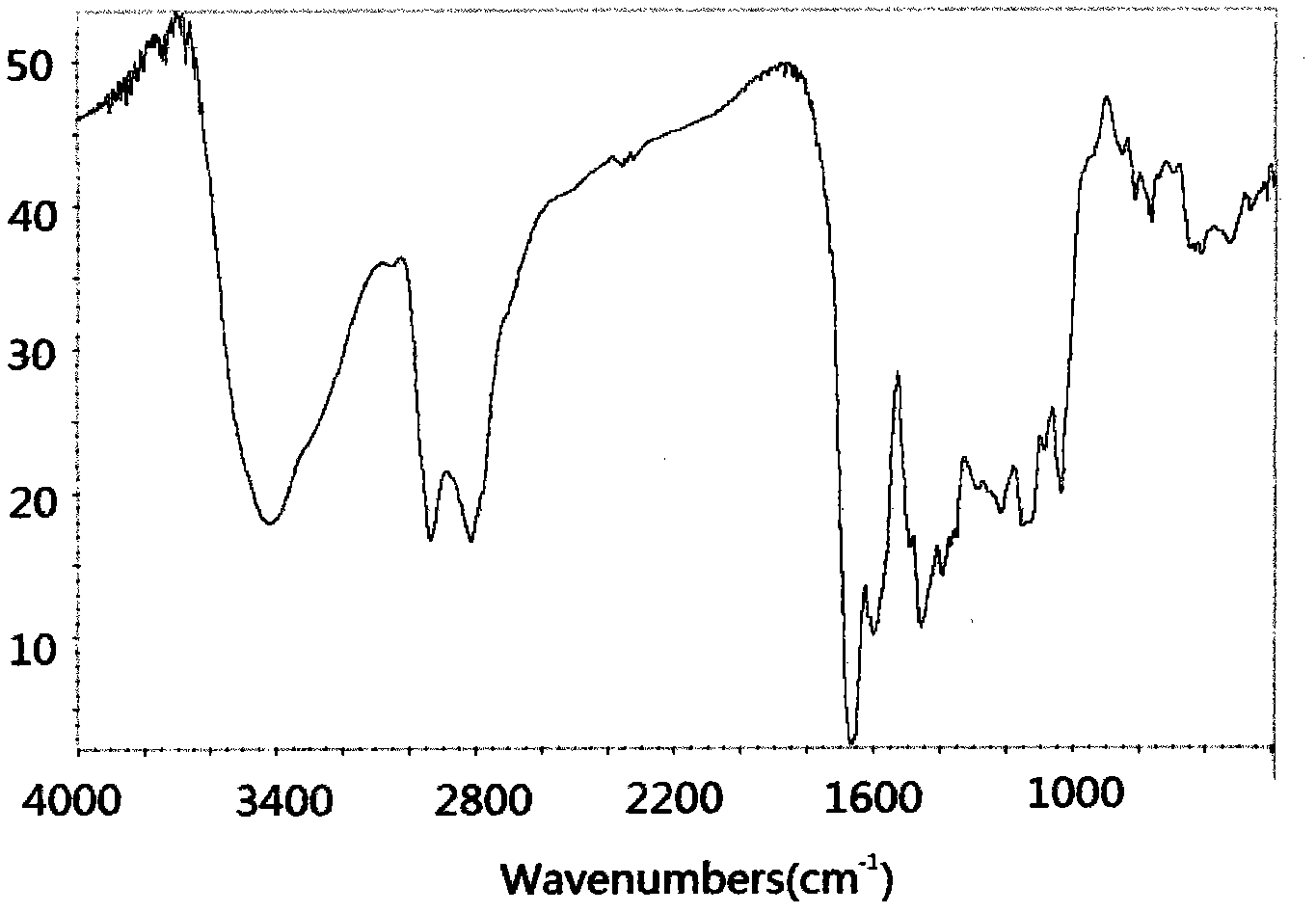

[0034] Example 1: Take 60 g of cyclohexanone wastewater (pH 9, COD 5000 mg / L) in a three-necked flask, add 16 g of alkali lignin, and stir to dissolve. Add 27g of formaldehyde solution with a mass concentration of 37% to the waste water, and stir for 15 minutes to dissolve it. Add 16 g of triethylenetetramine to the above waste water, stir for 10 min to dissolve it; raise the temperature to 85° C., and react for 3 hours to obtain a lignin amine solution. The infrared spectrum of the obtained product is as figure 1 As shown, the structure is consistent with the lignin amine prepared with water as solvent.

Embodiment 2

[0035] Example 2: Take 60 g of cyclohexanone wastewater (pH 11, COD 10000 mg / L) in a three-necked flask, add 12 g of alkali lignin, and stir to dissolve. Add 8g of acetaldehyde to the waste water, stir for 13min to dissolve it. Add 20 g of diethylenetriamine to the above wastewater, stir for 15 minutes to dissolve it; raise the temperature to 75° C., and react for 5 hours to obtain a lignin amine solution. After the reaction, the main pollutant cyclohexanone in the waste water was measured, and its concentration was reduced to less than 10% of that before the reaction, which indicated that the effective components in the waste water could participate in the reaction.

Embodiment 3

[0036] Example 3: Take 60 g of cyclohexanone wastewater (pH 13, COD 50000 mg / L) into a three-necked flask, add 20 g of alkali lignin, and stir to dissolve. Add 27g of formaldehyde solution with a mass concentration of 37% to the waste water, and stir for 15 minutes to dissolve it. Add 25 g of tetraethylenepentamine to the above wastewater, stir for 15 minutes to dissolve it; raise the temperature to 80° C., and react for 2 hours to obtain a lignin amine solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com