Gas plugging coating for wall surface of mine laneway

A roadway and wall surface technology, which is applied in the direction of fireproof coatings, conductive coatings, coatings, etc., can solve the problems of poor coating dispersion, high price, and numerous processes, and achieve the effects of reduced emissions, low cost, and large measurement environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

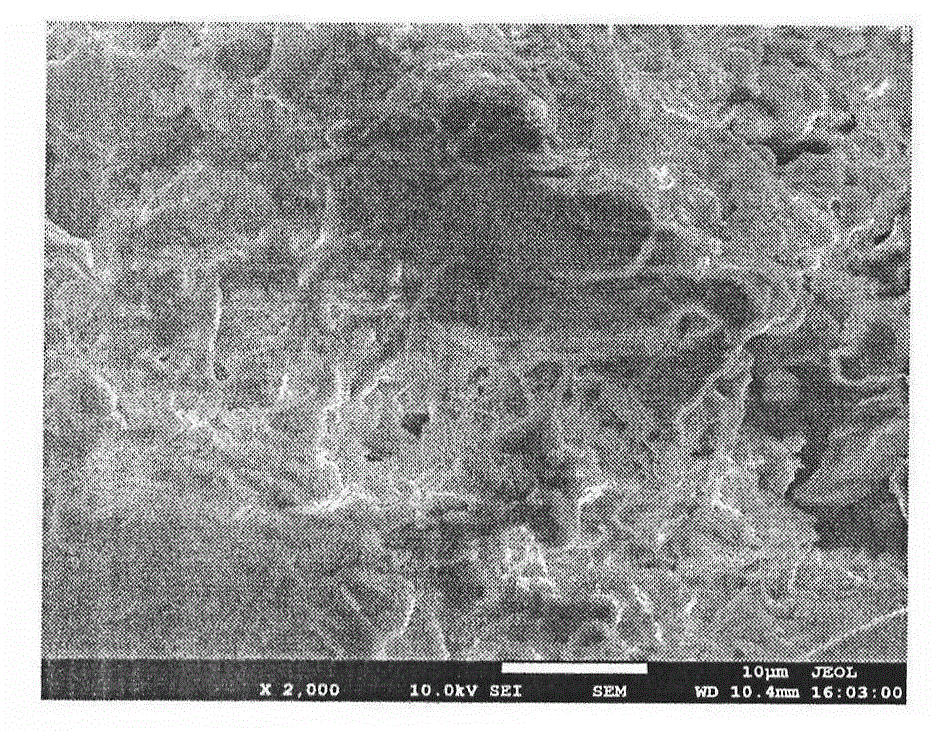

Image

Examples

Embodiment 1

[0021] Mix 60kg of ultra-fine fly ash with a particle size of 2.18μm, 20kg of slag Portland cement with a label of 325, 10kg of chlorinated paraffin, 5kg of aluminum hydroxide, 3kg of graphite, and 2kg of carbon black to form a powder; Take 50kg of flexible emulsion S400F and pour it into the mixing tank of the grouting pump, then add 30kg of water, stir evenly at a low speed, then add the above powder, continue stirring evenly, and then spray the mine roadway wall.

[0022] Test results:

[0023] 1) Appearance performance

[0024] The surface drying time of the coating is 10 minutes, and the hard drying time is 7 hours. After hard drying, the coating is smooth and without cracks;

[0025] 2) Mechanical properties

[0026] Untreated tensile strength 3.1MPa, elongation at break 83%, 0.3MPa 30min impermeable, in line with the standards specified in GB / T23445-2009 "Polymer Cement Waterproof Coatings";

[0027] 3) coal safety test

[0028] Flame resistance test: Alcohol lamp b...

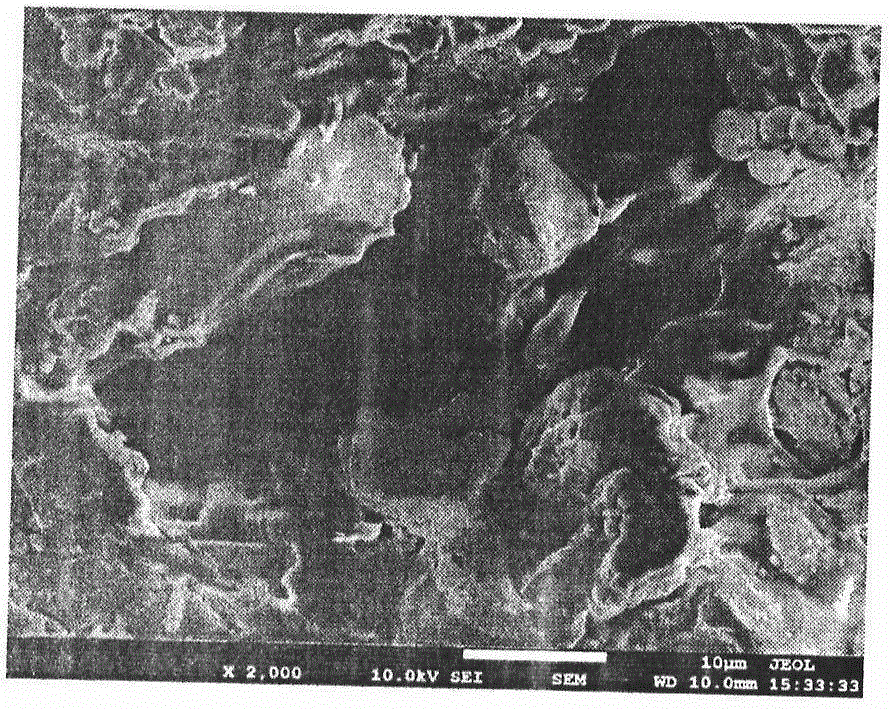

Embodiment 2

[0035] Mix 70kg of ultra-fine fly ash with a particle size of 3.76μm, 10kg of slag Portland cement with a label of 325, 12kg of chlorinated paraffin, 3kg of aluminum hydroxide, and 5kg of graphite to form a powder; take the flexible emulsion at the construction site Pour 50kg of S400F into the mixing tank of the grouting pump, then add 32kg of water, stir evenly at a low speed, then add the above powder, continue stirring evenly, and then spray the wall of the mine roadway.

[0036] Test results:

[0037] 1) Appearance performance

[0038] The surface drying time of the coating is 12 minutes, and the hard drying time is 7 hours. After hard drying, the coating has no cracks;

[0039] 2) Mechanical properties

[0040] Untreated tensile strength 3.5MPa, elongation at break 80%, 0.3MPa 30min impermeable, in line with the standards specified in GB / T23445-2009 "Polymer Cement Waterproof Coatings";

[0041] 3) coal safety test

[0042] Flame resistance test: Alcohol lamp burns wi...

Embodiment 3

[0048] Mix 75kg of ultra-fine fly ash with a particle size of 2.18μm, 5kg of slag Portland cement with a label of 325, 7kg of chlorinated paraffin, 8kg of aluminum hydroxide, 3kg of graphite, and 2kg of carbon black to form a powder; Take 50kg of flexible emulsion S400F and pour it into the mixing tank of the grouting pump, then add 38kg of water, stir evenly at a low speed, then add the above powder, continue stirring evenly, and then spray the wall of the mine roadway.

[0049] Test results:

[0050] 1) Appearance performance

[0051] The surface drying time of the coating is 13 minutes, and the hard drying time is 7.5 hours. After hard drying, the coating has no cracks;

[0052] 2) Mechanical properties

[0053] Nowhere is the tensile strength 3.4MPa, elongation at break 70%, 0.3MPa 30min impermeable, in line with the standards specified in GB / T23445-2009 "Polymer Cement Waterproof Coatings";

[0054] 3) coal safety test

[0055] Flame resistance test: Alcohol lamp burn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com