Filling and reinforcing method for floor roadway cross-layer pressure-relief borehole

A technology for layer penetration and rock roadway, which is applied in the field of floor rock roadway penetration pressure relief drilling, filling and reinforcement, and can solve the problems of restricting safe and efficient mining of a single soft and high outburst coal seam, uneven coal seam stress distribution, and difficulty in coal roadway support. , to achieve the effect of wide practicability, improving coal strength and improving support conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

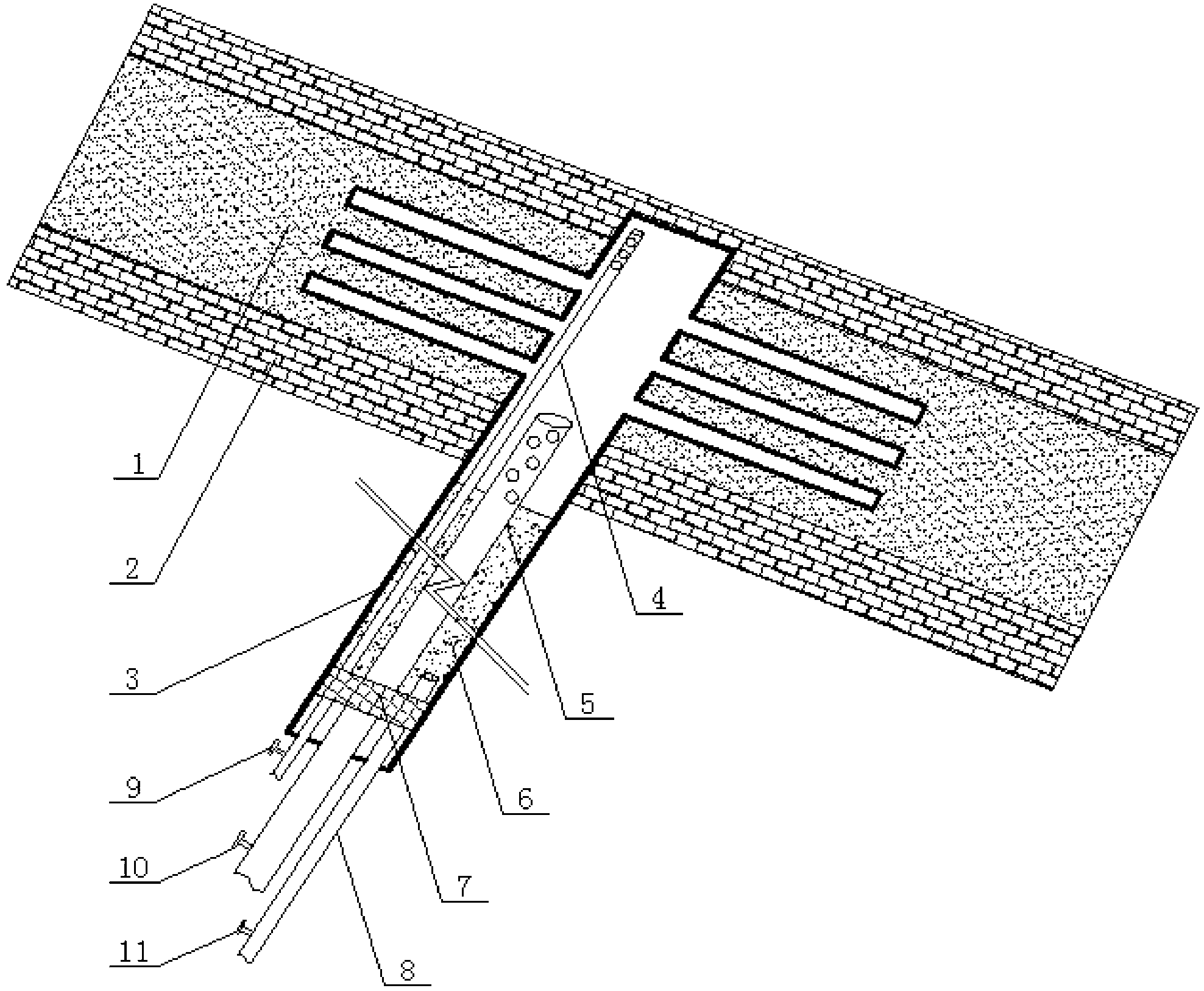

[0013] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0014] The filling reinforcement method of the floor rock roadway through the layer pressure relief drilling of the present invention: firstly, in the floor rock roadway drilling site, the common drilling is constructed in the coal seam 1 according to the routine, and then the pressure relief and permeability enhancement measures are adopted in the coal seam 1 through the common drilling Part of the coal body is discharged to form the pressure relief borehole 3 through layers. Wrap 2-4 polyurethane sealing bags 7 with adhesive tape at a distance of 5-6m from the orifice 5 of the gas drainage pipe 5 fed into the pressure relief borehole 3, where the polyurethane sealing bag 7 should be separated from the gas drainage The front end of the pipe 5 is not less than 5m; at the same time, the grouting pipe 8 is fixed at the lower part of the gas drainage pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com