Earth pressure balance shield structure with gate anti-spewing structure and shield method

An earth pressure balance shield and anti-surge technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of slow construction progress, scattered muck, and increased construction costs, and achieve less muck gushing. , to solve the effect of direct and large promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

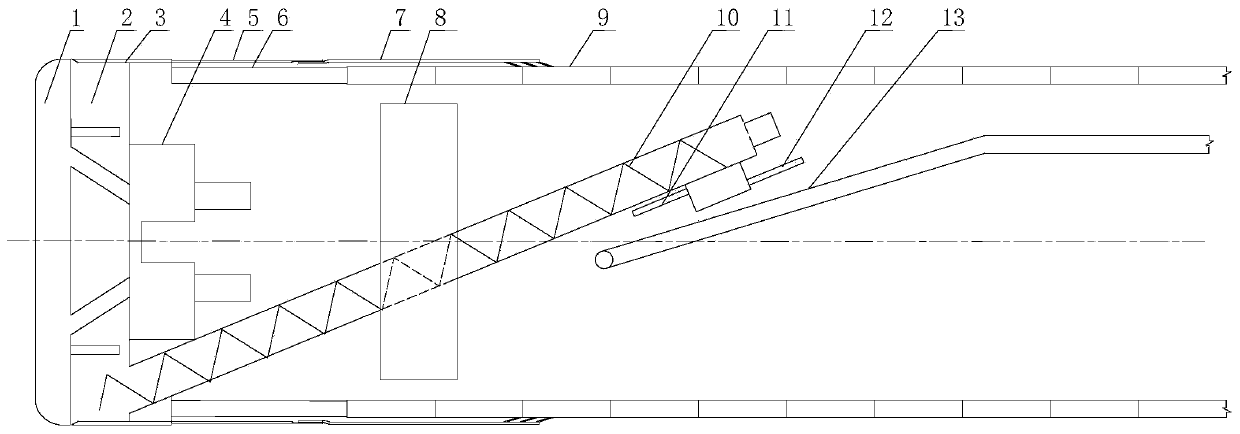

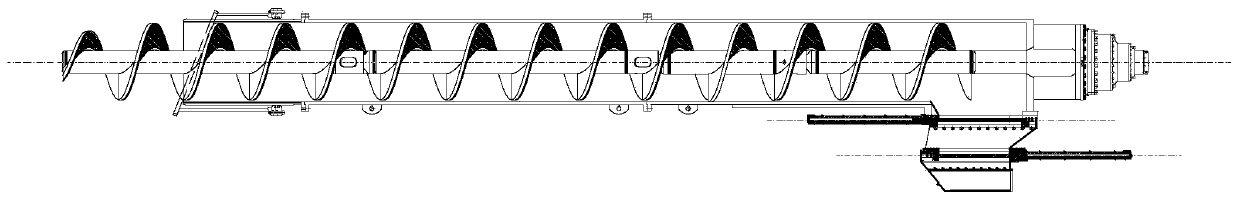

[0053] Such as figure 1 and figure 2 As shown, an earth pressure balance shield structure with a gate gushing-proof structure includes a cutter head 1, a front shield 3, a main drive 4, a middle shield 5, a shield tail 7, a propulsion cylinder 6 and a screw conveyor 10;

[0054] The propulsion cylinder 6 is placed on the front end surface of the segment 9, the soil cabin 2 is arranged behind the cutter head 1, and the main drive 4 is arranged behind the soil cabin 2; , the screw conveyor 10 is installed obliquely, and the slag outlet of the screw conveyor 10 is provided with an upper gate mechanism 11 and a lower gate mechanism 12; The cylinder is transported out; the muck falls on the belt 13 of the belt conveyor system through the upper gate mechanism 11 and the lower gate mechanism 12;

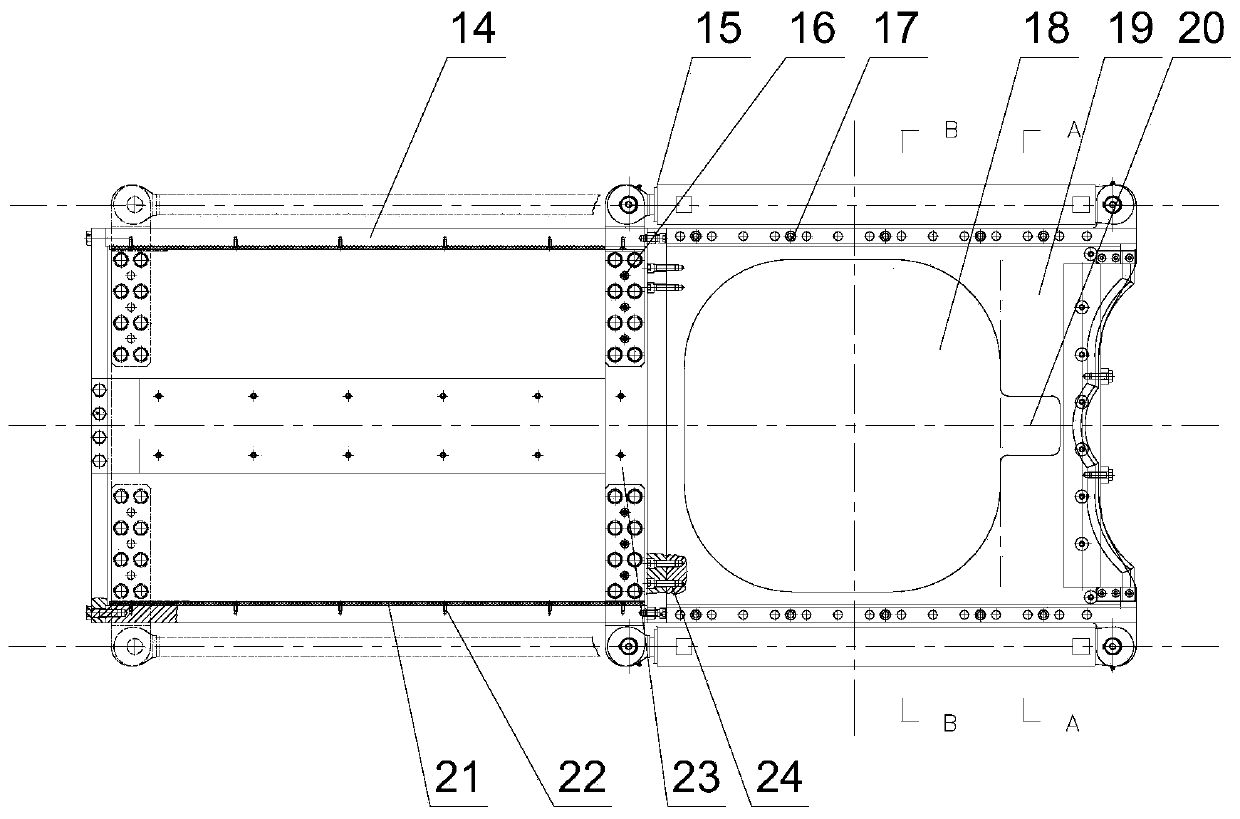

[0055] The upper gate mechanism 11 is provided with an upper gate plate 32 and an upper slag outlet. The upper slag outlet includes a first slag outlet 18 and an anti-spray slag outlet 2...

Embodiment 2

[0073] This embodiment is similar to Embodiment 1, the difference is that, for the upper gate mechanism 11 and / or the lower gate mechanism 12, it is improved as follows:

[0074] Sealing 25 is installed around the upper fixed plate 19 bottoms. The sealing device 25 can avoid the slag from falling and prevent the slag from leaking. In order to make the sliding of the upper gate plate 32 smoother and more stable, the number of the first oil cylinders 15 is two, and the two first oil cylinders 15 are arranged on both sides of the upper fixed plate 19 respectively. The first oil cylinder 15 on the side is balanced, and the stability and reliability are enhanced (the number of the second oil cylinder 37 is two, and the two second oil cylinders 37 are respectively arranged on both sides of the upper fixing plate 19).

[0075] In order to ensure the lubrication between the upper gate plate 32 and the second wear plate 26, as Figure 4 As shown, grooves are slotted on the second wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com