Upstream-blocking and downstream-seepage method for extracting gas in mining area

A mining area and gas technology, applied in gas discharge, mining equipment, earthwork drilling, etc., can solve problems such as affecting gas, and achieve the effects of improving gas extraction rate, preventing gas explosion, and reducing gas gushing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

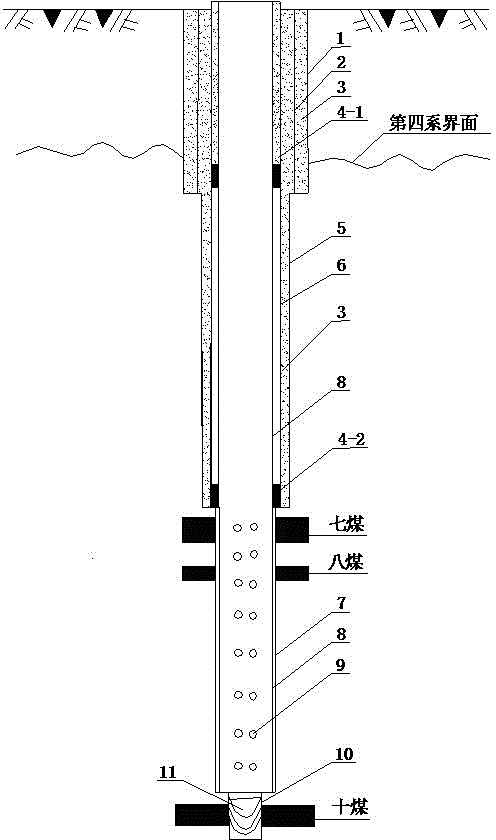

[0017] like figure 1 As shown, the method for mining gas in the mining area by plugging up and down seepage includes the following steps:

[0018] A. Use the drill bit to drill from the surface to the bedrock hard disk 20m~30m below the Quaternary interface to drill a drill hole 1, drill a casing 2 in the drill hole 1, and then drill a casing 2 Inject cement slurry 3 between the drill hole 1 and cement the well;

[0019] B. Use a drill bit with a diameter smaller than the inner diameter of the first casing 2 to drill the second drilling hole 5 at a place 5m to 6m above the roof of the seventh coal seam. Lower the second casing 6 whose diameter is smaller than the second hole 5, and then inject cement slurry 3 between the second casing 6, the first casing 2, and the second hole 5 for cementing;

[0020] C. Use a drill bit with a diameter smaller than the inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com