Method for controlling gas of mountain angle and worked-out section by one-in one-out and alternate tail lane ventilation mode

A technology of internal staggered tailings and ventilation methods, which is applied in the direction of gas discharge, earth drilling, mine/tunnel ventilation, etc., and can solve problems such as poor drainage system, difficult management, and large impact of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

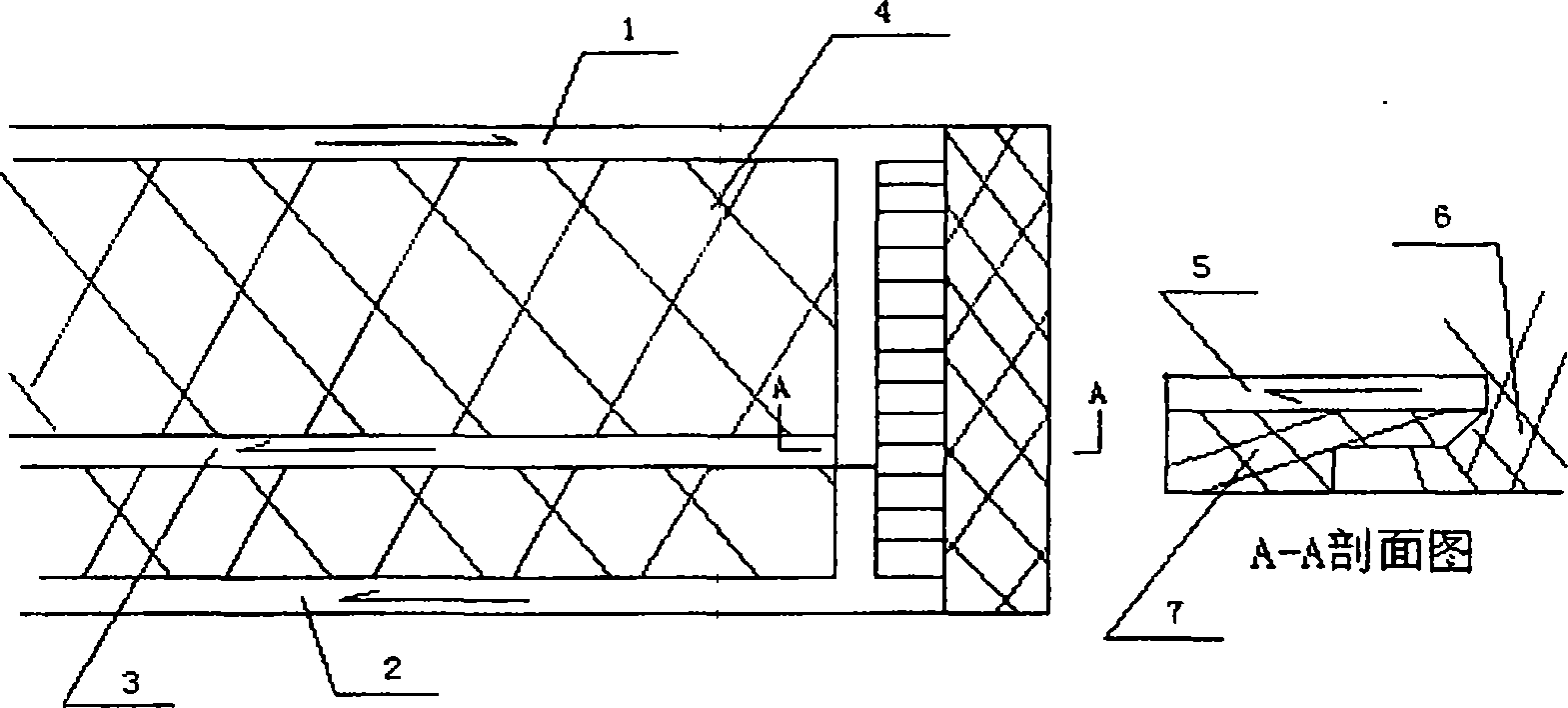

Image

Examples

Embodiment Construction

[0018] Using the method of increasing resistance and boosting pressure, that is, setting up two regulating air cards in the return air lane of the working face to ensure that the pressure is stable when pedestrians and materials are transported. The overall pressure increase of the face return air drop-off corner, the stope range of the working face and even the goaf; at the same time, it will also reduce the ventilation pressure of the tail lane and increase the air volume, which is more conducive to the collection of gob gas in the tail lane and inhibit the return of gas to the drop-down area. build up. The range of resistance increase and pressure adjustment is generally not too large. The pressure difference between the return air lane and the tail lane is generally maintained at 20-60Pa, and the air volume of the tail lane accounts for 40% of the total air intake. Depending on the specific situation, the pressure difference should be adjusted appropriately depending on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com