Goaf roof high-position directional borehole gas extraction technology

A technology of directional drilling and high-level drilling, which is used in mining equipment, earth-moving drilling, gas discharge, etc., can solve the problems of high extraction cost and low driving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

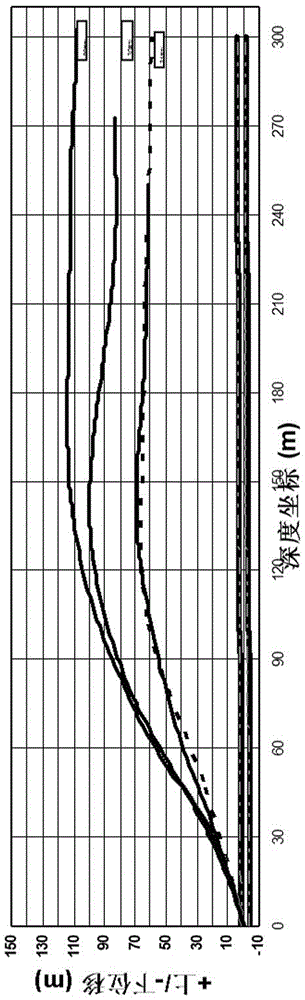

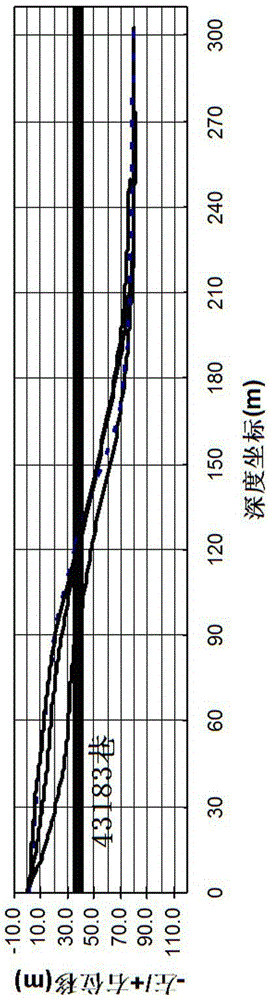

[0014] A high-level directional drilling drainage process on the roof of the goaf. With the recovery of the working face, a mining pressure field is formed around it. The mining pressure field and its influence range form three zones in the vertical direction from bottom to top. , that is, the caving zone, fissure zone and curved subsidence zone. In the mining pressure field above the goaf, a kilometer directional drilling rig is used to construct high-level drilling, with one upper, middle and lower drilling.

[0015] Such as figure 1 As shown, the goaf is divided into a coal pillar section and a goaf section, the coal pillar section is solid coal (between lanes 43182-43183), and the high-level drilling in the goaf section can be constructed in the caving zone And in the fissure zone, after the coal pillar goes out to the goaf, the borehole is raised to the fissure zone, and the elevation height is not less than 35 meters.

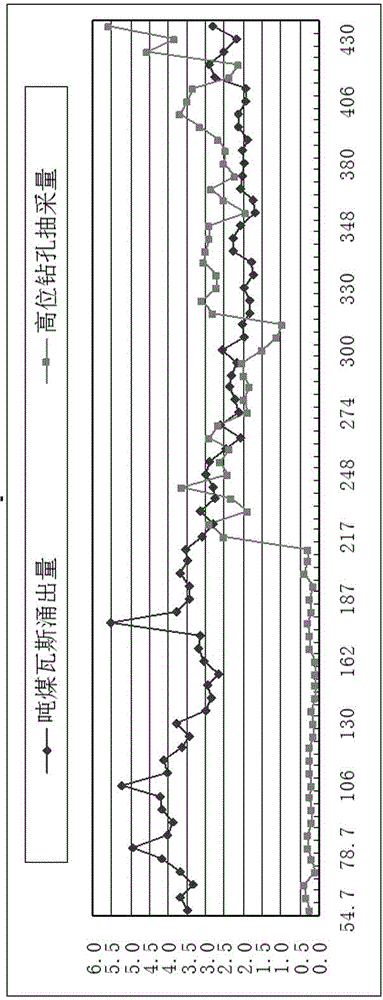

[0016] According to the simulation results of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com