Combined spontaneous gas and coal combustion control method during roof cutting lane forming non-pillar mining

A coal pillar-free, coal spontaneous combustion technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve problems such as coal spontaneous combustion, air leakage in gobs, and threats to safe mining of coal seams, so as to ensure safe production and reduce gas surges output, avoiding gas overrun and the effect of coal spontaneous combustion hazard in goaf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

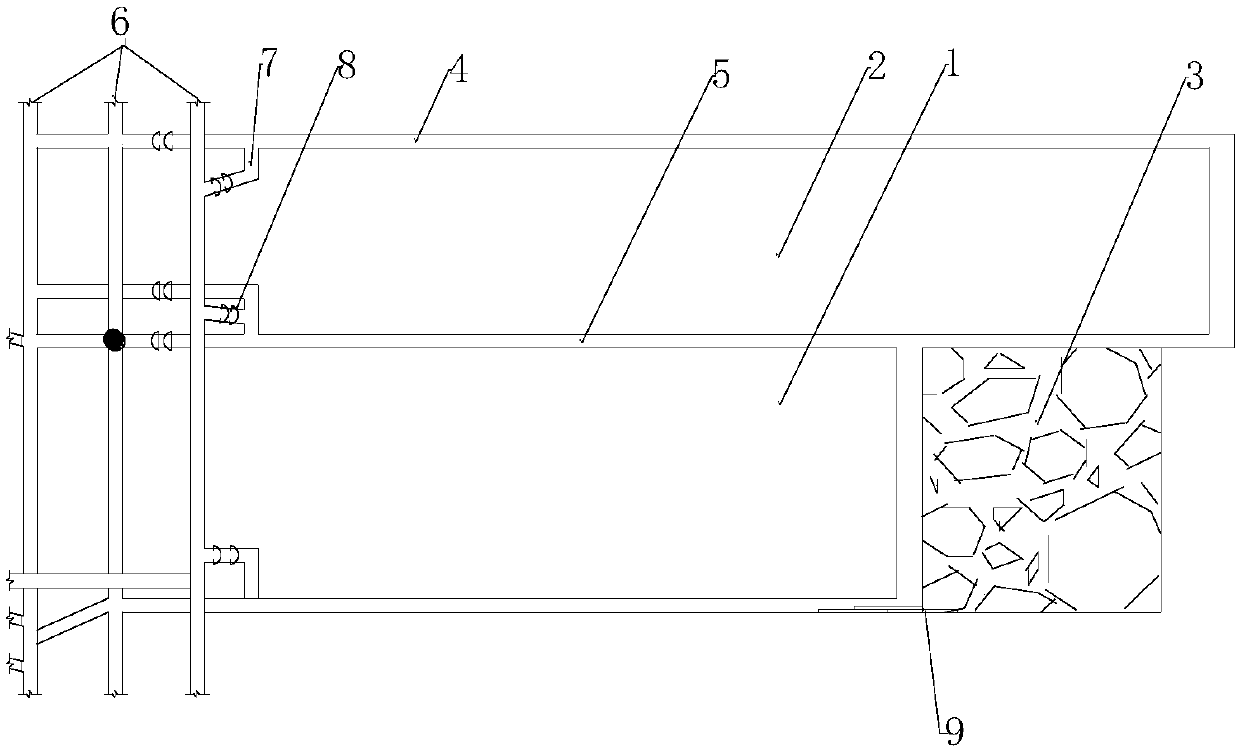

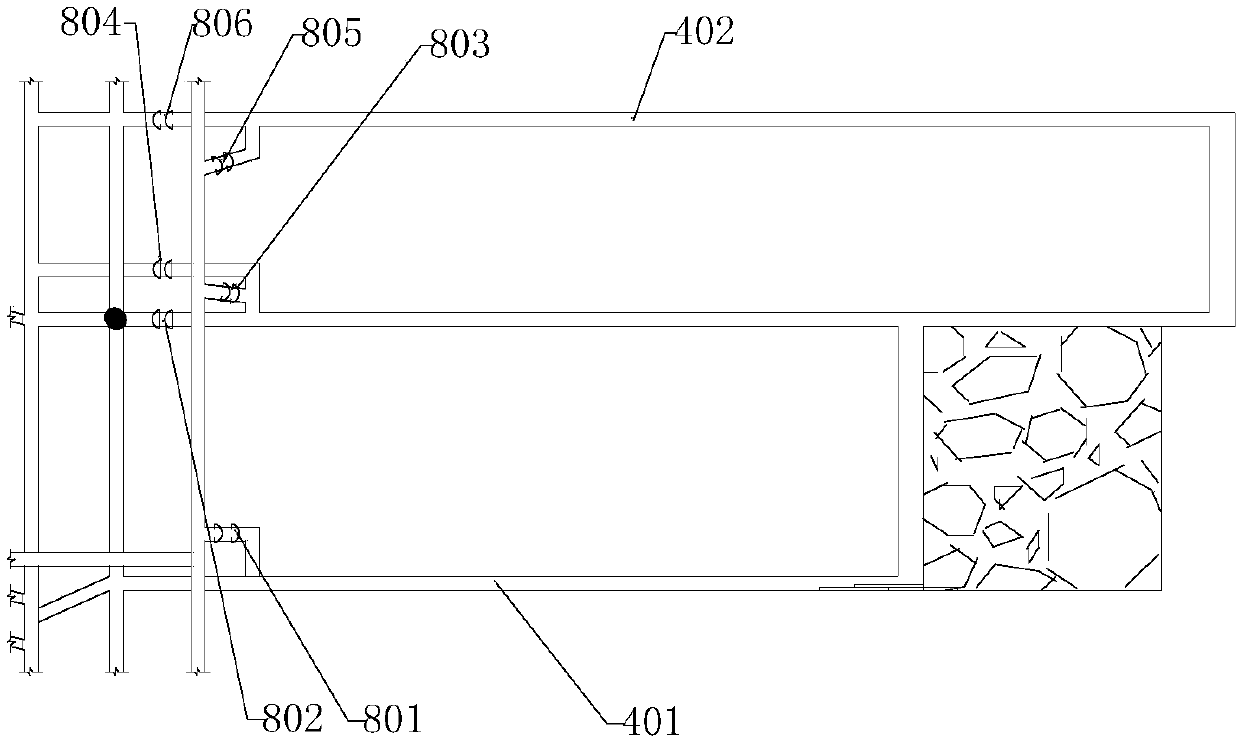

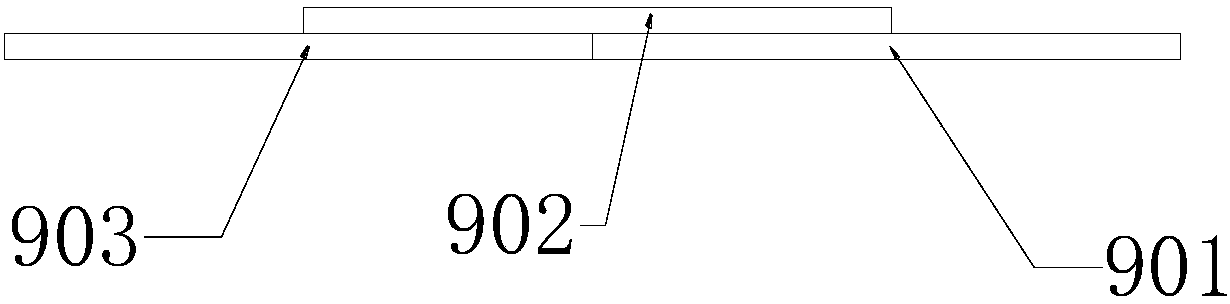

[0016] Such as Figure 1~3 As shown, a method for co-governing gas and coal spontaneous combustion in roof-cutting and roadway mining without coal pillars of the present invention includes an E-type working face ventilation system, and a technology of stepping pipe laying and injecting liquid carbon dioxide in the goaf, wherein the E-type working face is ventilated The system consists of roadways 4 on both sides, middle roadway 5, mining area downhill (uphill) 6, and connecting roadway 7. The E-type working face ventilation system is used to control the gas gushing out of the current mining face 1, and can reduce the current mining face 1. The pressure difference at both ends reduces the air leakage to goaf 3; the technology of stepping pipe laying and injecting liquid carbon dioxide in goaf is used to prevent coal spontaneous combustion in gob 3. Liquid carbon dioxide has dynamic effects such as cooling and inerting, and its density ratio The air is large, and it is easy to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com