Roofbolt constructing method in civil engineering

A technology of anchor bolt construction and civil engineering, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of low pullout resistance of anchor bolts, difficulty in lowering anchor bars, etc., and meet the needs of foundation pit support and construction procedures The effect of reducing and enlarging the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

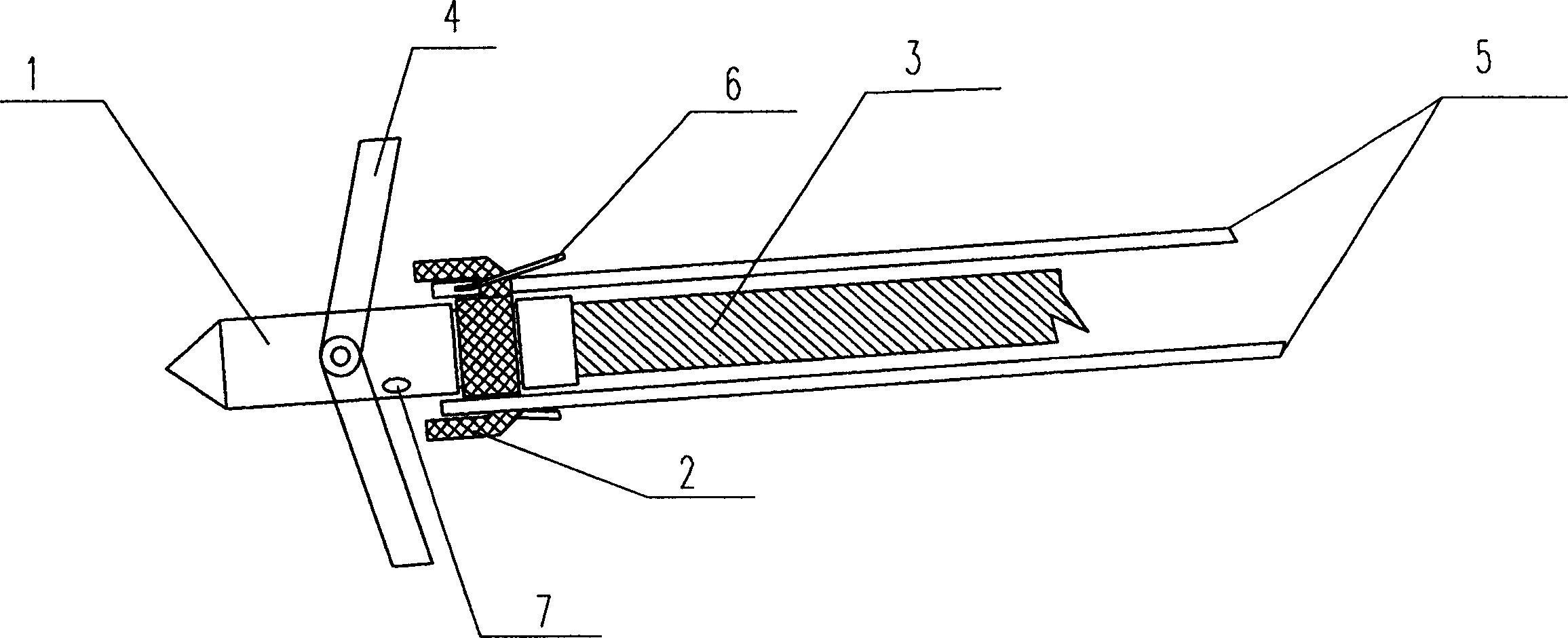

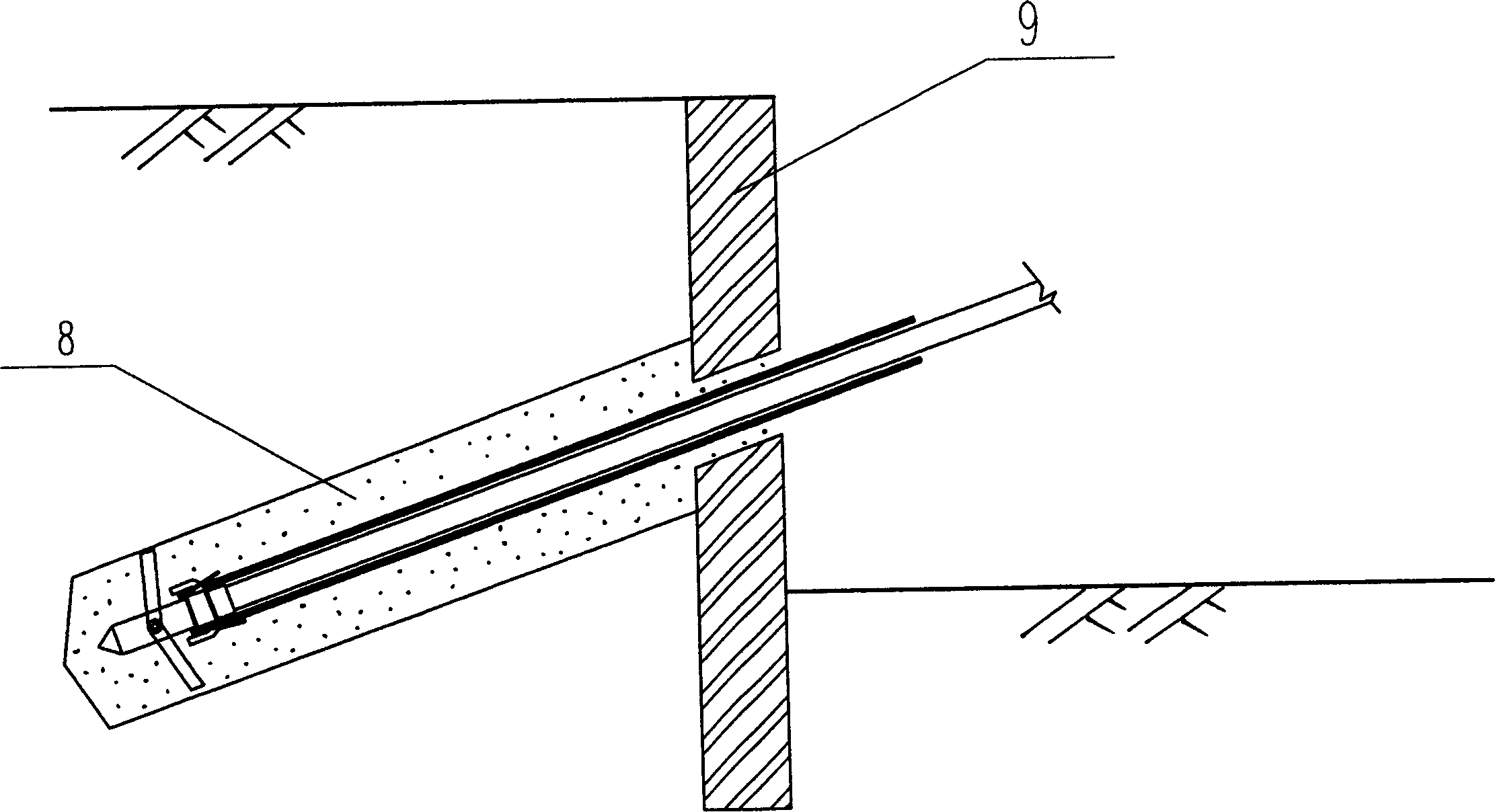

[0022] First, open a Φ120 hole on the support pile 9 of the foundation pit, and connect the movable hook 2 to the rear end of the drill bit 1. The movable hook 2 can rotate freely relative to the drill bit 1, but cannot move freely, that is, the movable hook 2 It needs to move back and forth with the drill bit 1; hinge the drill piece 4 on the drill bit 1, and the drill piece 4 is located at the front end of the movable hook 2; disassemble and fold back the steel wires 6 at the front ends of the two 7Φ5 steel hinge lines 5, and put the steel wires together. The line 6 is buckled on the movable hook 2, that is, when the movable hook 2 moves forward, the anchor rib 5 is moved forward, and when the movable hook 2 moves backward, the anchor rib 5 can be separated from the movable hook 2 , fix the drill pipe 3 and the drill bit 1 with threaded connection, see the connection relationship of each part figure 1 Shown; close up the drill piece 4 on the drill bit 1, pass the drill bit 1...

Embodiment 2

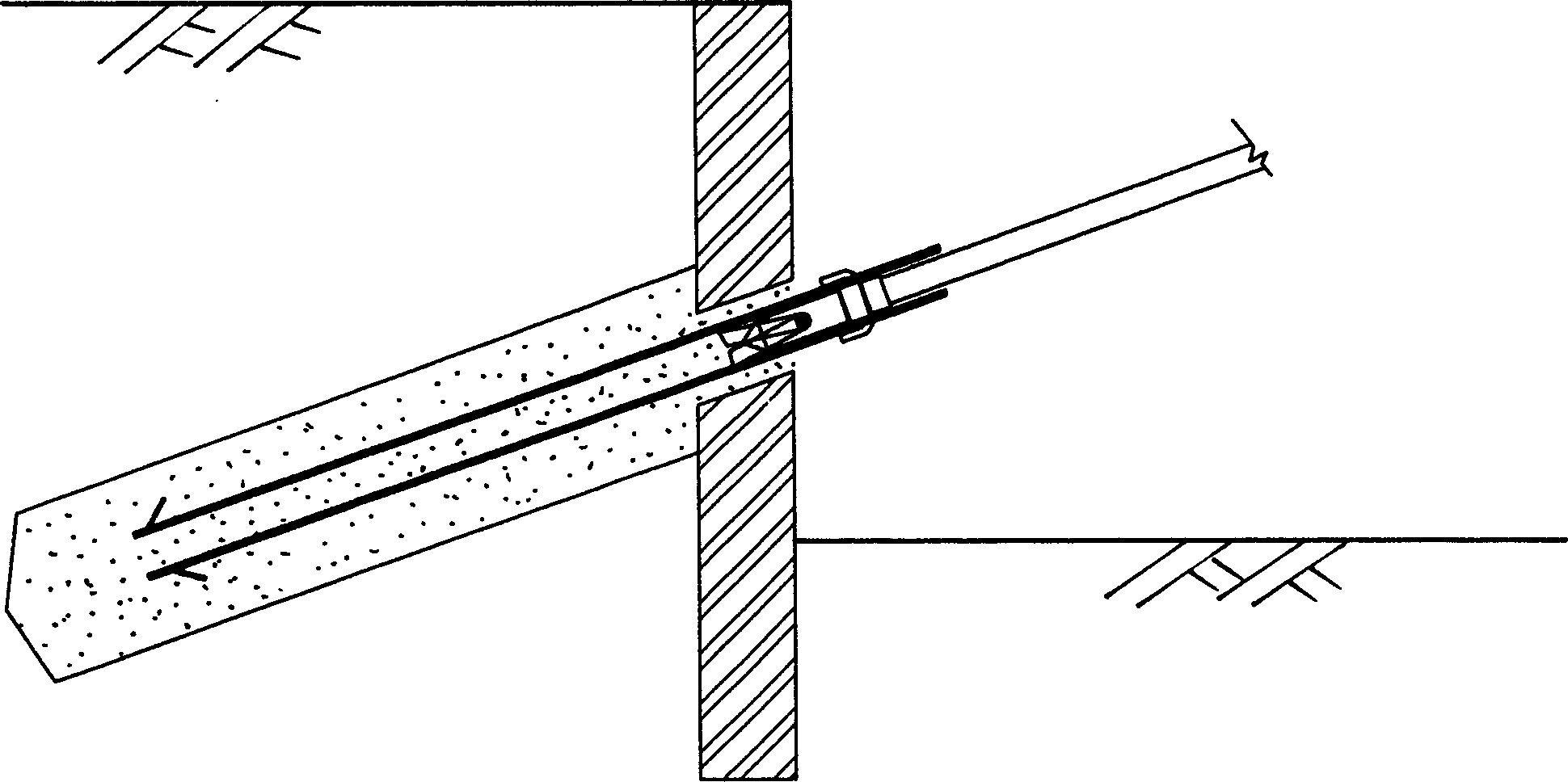

[0024] In Embodiment 1, the steel hinge wire 5 is replaced with Φ25 steel bars 10, two reflexed steel bars 11 are welded at the front ends of the steel bars 10, the reflexed steel bars 11 are buckled on the movable hook 2, and the extension of the movable hook 2 The arm is set to be foldable, that is, the arm stretches out when drilling forward, and retracts when moving backward, so as to reduce the resistance when the drilling rod 1 etc. is pulled out. The connection of other parts is the same as that in the first embodiment; start the drilling rig, use mud circulation fluid, rotate the drill bit 1 to drill forward and drive the Φ25 steel bar 10 to follow up through the movable hook 2, and after drilling to the predetermined depth, clean the hole, and then pour cement at the same time The 8 sides of the slurry continue to drill forward, such as Figure 4 As shown: After reaching the designed length of the anchor rod, pull out the drill pipe 3, drill bit 1, drill piece 4 and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com