Magnetic solid acid catalyst and application thereof to extracting saponin

A magnetic solid acid and catalyst technology, applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve problems such as biomass hydrolysis research, and achieve practicability and applicability wide range, mild reaction conditions, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

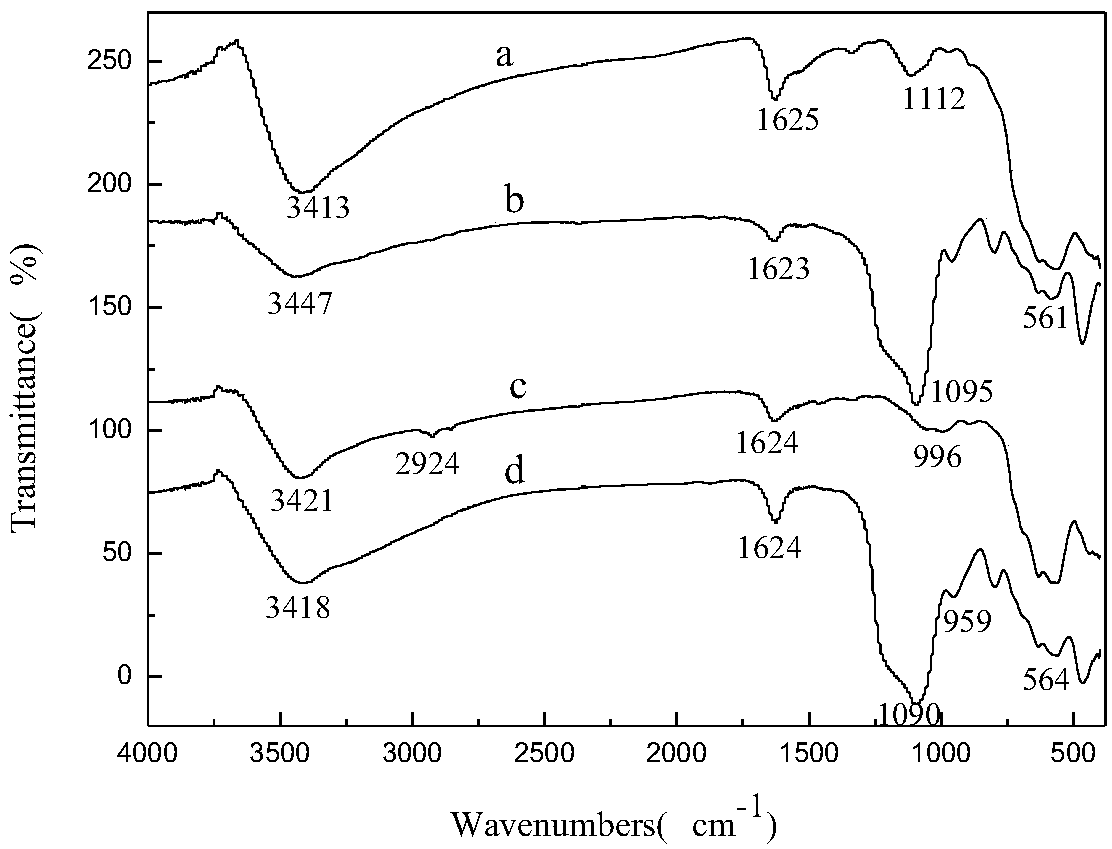

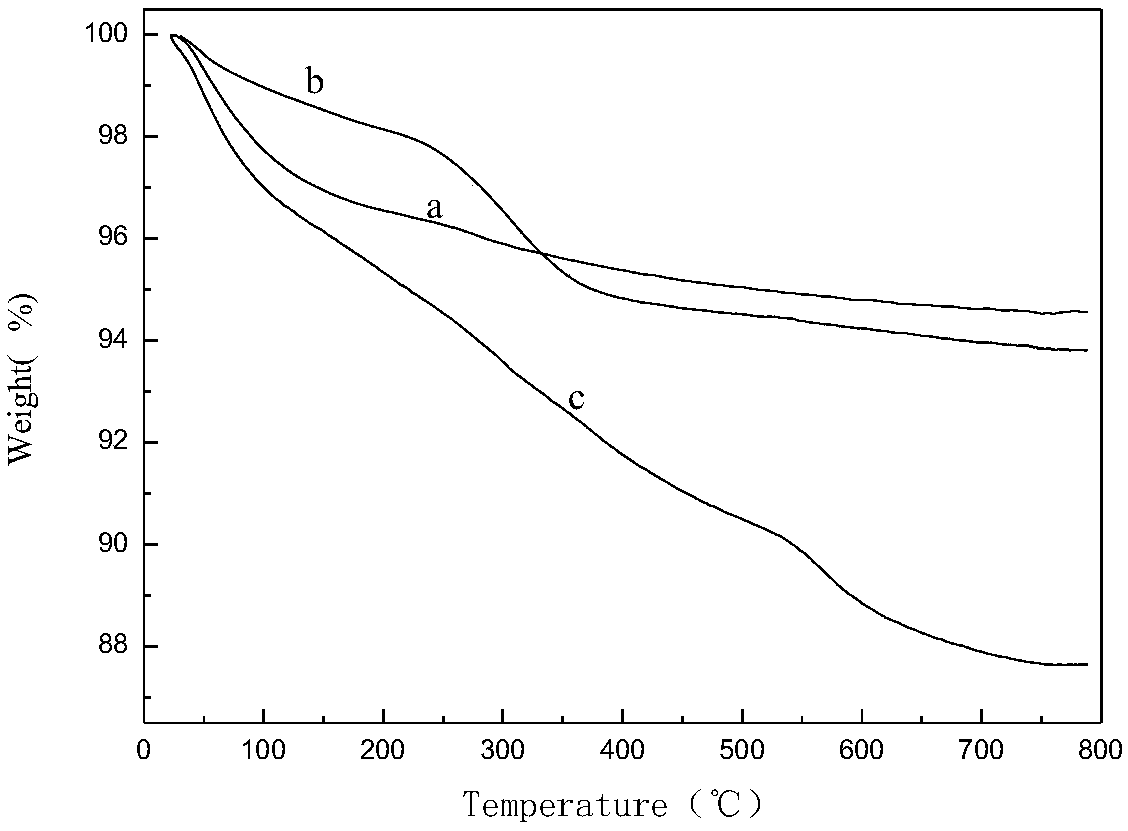

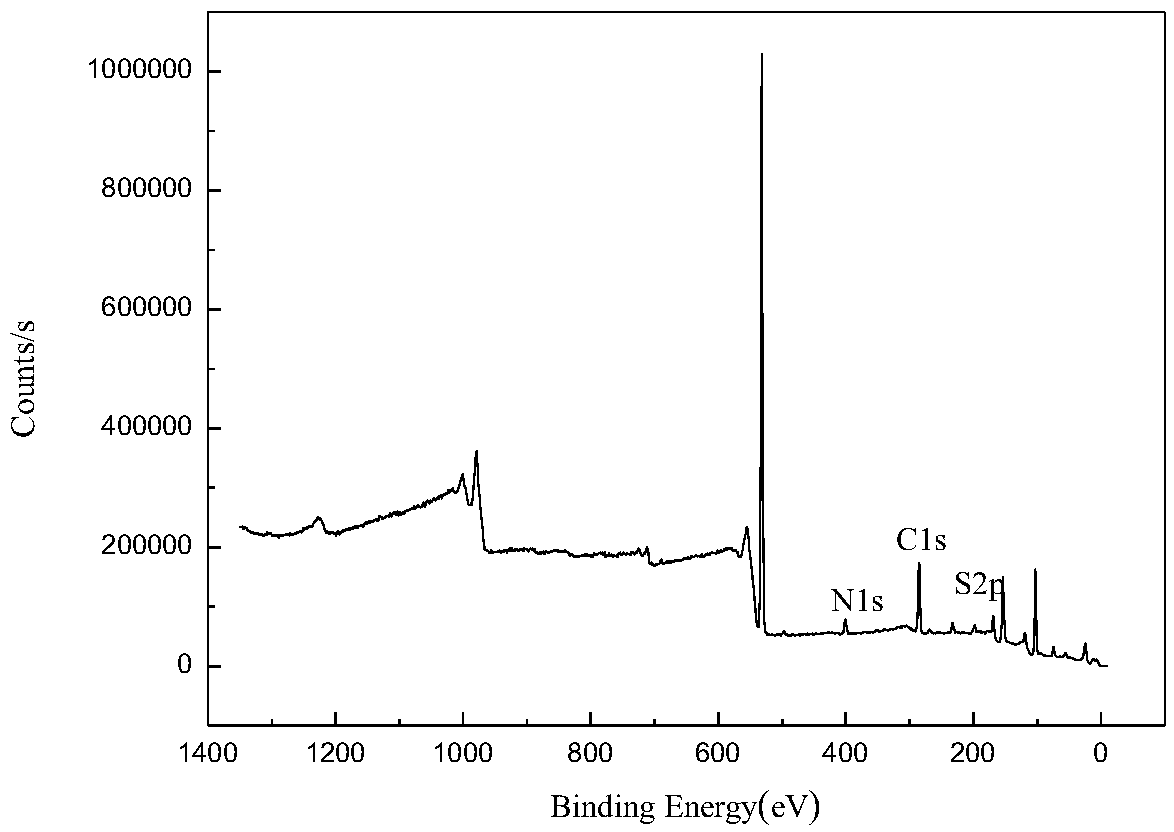

[0045] A kind of magnetic solid acid catalyst, its preparation method comprises the steps:

[0046] 1) Fe 3 o 4 Granules and tetraethoxysilane as the main raw materials were prepared by sol-gel method to Fe 3 o 4 @SiO 2 Particles; specifically comprise the steps of: weighing Fe 3 o 4 Particles (1.0g) were dispersed in a mixed solution of 60mL of absolute ethanol and 15mL of distilled water by ultrasound for 10min, mechanically stirred at room temperature for 20min, and then 1mL of ammonia water was added (one-time addition); after stirring evenly, 1mL of TEOS+10mL of Water ethanol solution (30min drop); stir at room temperature for 16h after dropwise addition; use magnet to separate Fe 3 o 4 @SiO 2 Particles were washed three times with distilled water and ethanol, and dried under vacuum at 60°C;

[0047] 2) Weigh 1g Fe 3 o 4 @SiO 2 Particles, ultrasonically dispersed in a mixed solution of 60mL ethanol and 15mL distilled water, mechanically stirred for 20min at ro...

Embodiment 2

[0054] Step 1 described in embodiment 2) adopts sol-gel method to prepare Fe 3 o 4 @SiO 2 Particle, and step 3) sulfonation reaction is identical with embodiment 1, difference is: step 2) Fe 3 o 4 @SiO 2 @NH-(CH 2 ) 2 -NH 2 The preparation conditions of the particles are different. Its preparation method is as follows:

[0055] Weigh 1g Fe 3 o 4 @SiO 2 Particles were ultrasonically dispersed in a mixed solution formed by 25mL of anhydrous toluene, mechanically stirred at 110°C for 2h under the protection of argon, and after stirring evenly, 2mL of N-[3-(trimethoxysilyl)propane was added dropwise with a constant pressure funnel. Base] ethylenediamine solution, continue to mechanically stir for 18h; use a magnet to separate Fe 3 o 4 @SiO 2 @NH-(CH 2 ) 2 -NH 2 , washed three times with distilled water and ethanol, and dried under vacuum at 60°C.

Embodiment 3

[0057] Step 1 described in embodiment 3) adopts sol-gel method to prepare Fe 3 o 4 @SiO 2 Particle, and step 3) sulfonation reaction is identical with embodiment 1, difference is: step 2) Fe 3 o 4 @SiO 2 @NH-(CH 2 ) 2 -NH 2 The preparation conditions of the particles are different. Its preparation method is as follows:

[0058] Weigh 0.5g Fe 3 o 4 @SiO 2Particles, ultrasonically dispersed in the mixed solution formed by 50mL cyclohexane, add 1.5g Span-80, mechanically stir at room temperature for 20min, then add 1mL of ammonia water (one-time addition), after stirring evenly, add 1mL dropwise with a constant pressure funnel N-[3-(trimethoxysilyl)propyl]ethylenediamine solution, continue to stir at room temperature for 16h; use a magnet to separate Fe 3 o 4 @SiO 2 @NH-(CH 2 ) 2 -NH 2 , washed three times with distilled water and ethanol, and dried under vacuum at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com