Making process of strong acid ion exchange fiber

A technology of ion exchange fiber and manufacturing method, which is applied in the field of chemical fiber material manufacturing and strong acid ion exchange fiber manufacturing, can solve the problems of low utilization rate of grafted monomers, easily damaged fiber matrix, and insufficient acid strength, and achieve industrialization The effect of easy promotion and implementation, short production process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

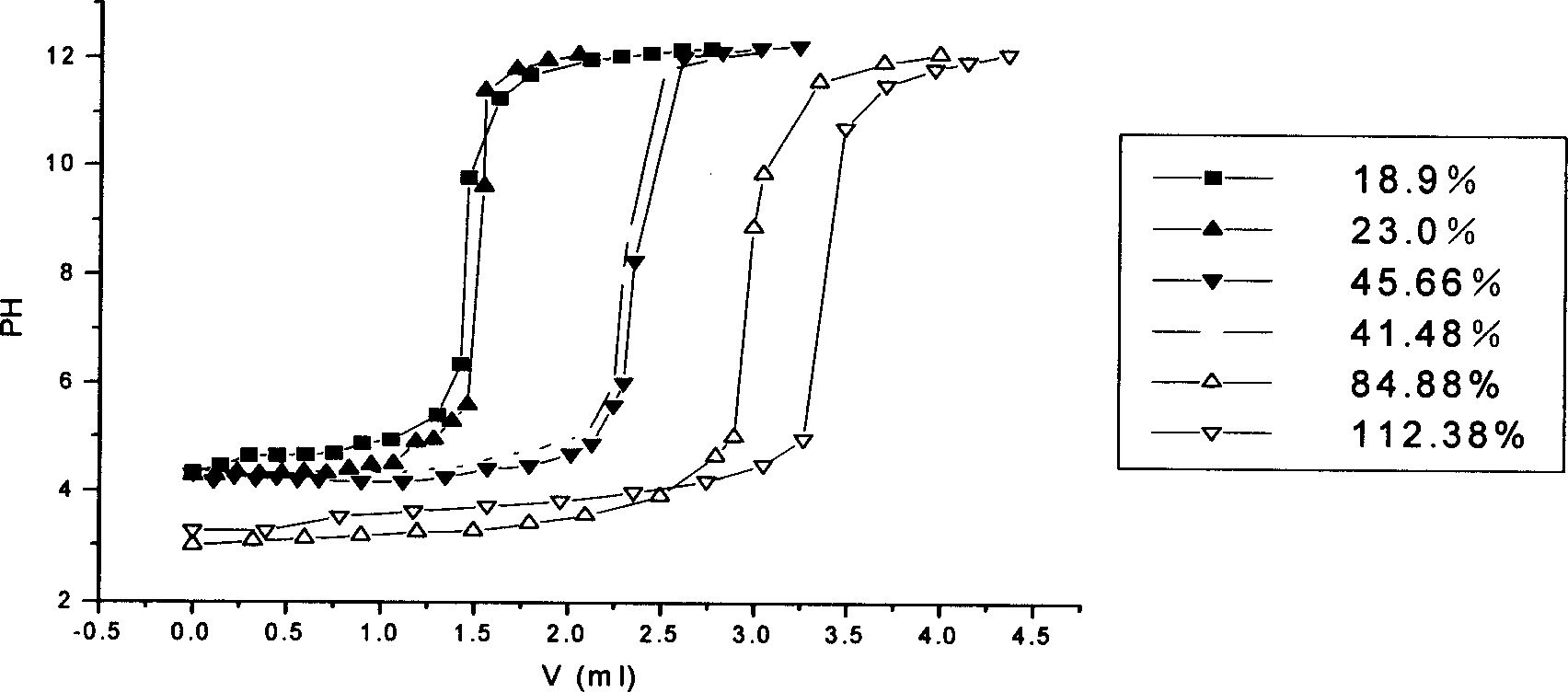

Embodiment 1

[0025] Immerse the polytetrafluoroethylene fibers in a homogeneously mixed solution of 70% styrene and 30% dichloromethane by volume, pass through nitrogen protection, and irradiate 30KGy with cobalt 60 at room temperature for 80 hours to obtain grafted fibers, take them out and wash them and then immersed in a homogeneously mixed solution of 30% by volume of chlorosulfonic acid and 70% of tetrachloroethane, carried out sulfonation reaction at 100°C, cooled and washed to obtain the strong acid ion exchange fiber. After testing, the fiber has an exchange capacity of 3.8mmol / g, can be used for ion exchange, has strong acidity (pH value is 2.92), and can also be used as a solid acid catalyst.

Embodiment 2

[0027] Immerse the polytetrafluoroethylene fibers in a homogeneously mixed solution of 40% styrene and 60% methylene chloride by volume, pass through nitrogen protection, and irradiate 30KGy with cobalt 60 at room temperature for 80 hours to obtain grafted fibers, take them out and wash them Then immerse it in a homogeneous mixed solution of 40% chlorosulfonic acid and 60% tetrachloroethane by volume, carry out sulfonation reaction at 90°C, wash after cooling, and obtain the strong acid ion exchange fiber. After testing, the fiber has an exchange capacity of 2.7mmol / g, can be used for ion exchange, has strong acidity (PH value is 3.85), and can also be used as a solid acid catalyst.

Embodiment 3

[0029] Soak the polytetrafluoroethylene fibers in a homogeneously mixed solution of 60% styrene and 40% dichloromethane by volume, pass through nitrogen protection, and irradiate 30KGy with cobalt 60 for 80 hours at room temperature to obtain grafted fibers, take them out and wash them Then immerse it in a homogeneous mixed solution of 40% chlorosulfonic acid and 60% tetrachloroethane by volume, carry out sulfonation reaction at 100°C, wash after cooling, and obtain the strong acid ion exchange fiber. After testing, the fiber has an exchange capacity of 3.5mmol / g, can be used for ion exchange, has strong acidity (PH value is 3.25), and can also be used as a solid acid catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com