Process for producing sulfanilic amide medicine mother substance p-acetamido benzene sulfonyl chloride

A technology of acetamidobenzenesulfonyl chloride and production process, which is applied in the field of production technology of sulfonamide drug parent-p-acetamidobenzenesulfonyl chloride, can solve problems such as failure to obtain economical, effective and applicable technical measures, and achieves environmental protection and saving Water use, the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

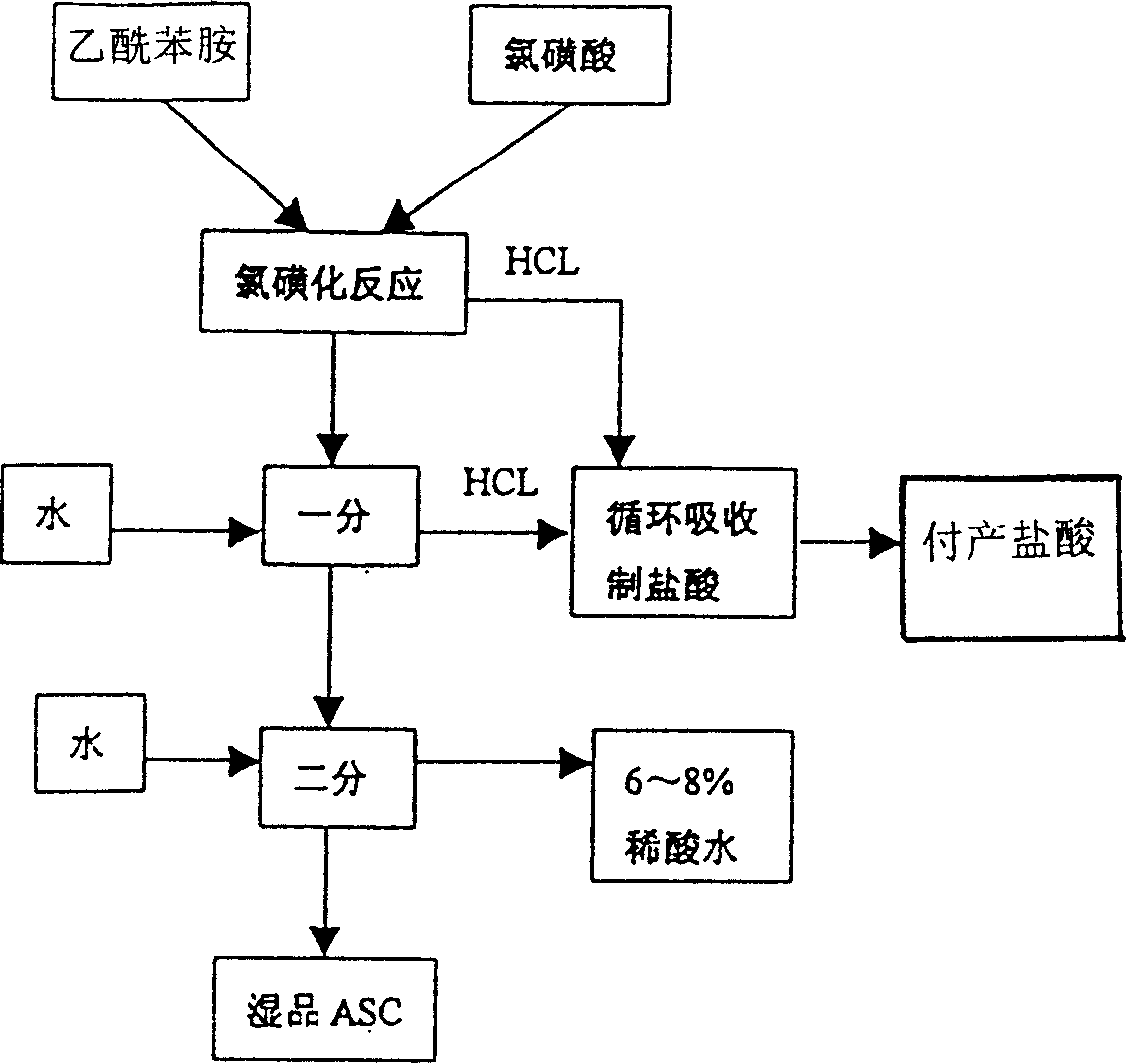

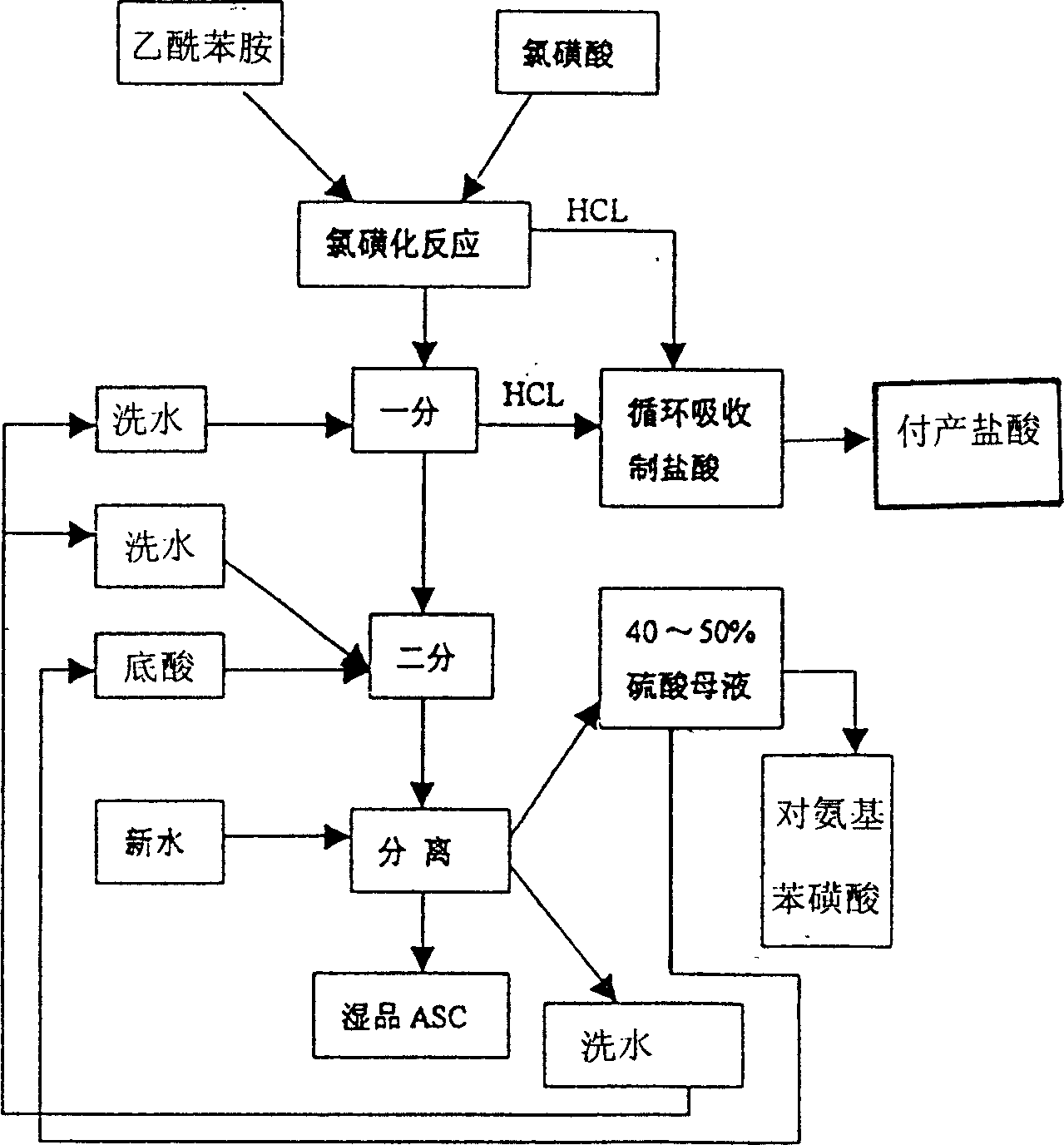

[0008] refer to figure 2 , this embodiment is firstly the chlorosulfonation reaction: add 1000L chlorosulfonic acid into a 2000L sulfonation kettle, start stirring, and cool the jacket with ice water; under slight negative pressure, slowly add acetanilide from the high-level silo , add 400Kg of acetanilide within 1.5 hours; keep the reaction temperature at 48-50°C; react for 6 hours, cool down to 30°C to obtain sulfonated oil, pump it into a static reaction tank, and keep it warm for 8 hours; by-product hydrogen chloride gas enters hydrochloric acid The absorption tower absorbs the by-product hydrochloric acid. Jingyifen: pump the sulfonated oil into a subdivision kettle, and pass through the jacket with frozen brine; add 1 / 10 of the oil volume washing water dropwise at 20-22°C to decompose the chlorosulfonic acid, and the hydrogen chloride gas produced enters the hydrochloric acid The absorption tower absorbs and obtains by-product hydrochloric acid. After two points: In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com