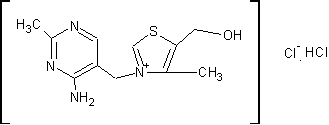

Novel method for synthesizing vitamin B1 hydrochloride

A vitamin and hydrochloride technology, applied in the direction of organic chemistry, can solve the problems of high toxicity of barium chloride, difficult implementation, and difficult removal of ammonium chloride, and achieve the effect of environmental friendliness and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] time w / w%SO 4 2- 0.5h 3.5 1.5h 0.5 2.5h 0.25 3.0h 0.01

[0023] The resin was filtered off, washed with 100 g of purified water, and the filtrate (90 g) and washings (90 g) were analyzed separately. Analyze sulfate content and thiamine hydrochloride content.

[0024] w / w% Thiamine Hydrochloride 22.000 w / w%SO 4 2- 0.010 w / w% yield 90.000

[0025] w / w% Thiamine Hydrochloride 2.100 w / w%SO 4 2- 0.001 w / w% yield 8.690

[0026] Combine the filtrate and washing liquid and add them to a rotary evaporator to concentrate until some substances are precipitated, then add 200g of ethanol, cool down to 0°C, let it crystallize completely, filter, and dry to obtain 20.5g of vitamin B 1 Hydrochloride. The analytical content is 99.9 w / w %, sulfate, nitrate, absorption and other indicators are qualified.

[0027] The resin was regenerated with 1000 g of aqueous sodium hydroxide solution ...

Embodiment 2

[0029] Continuous process:

[0030] At 25°C, 400ml of wet resin 330 (cl - type) into the column, wash the resin with 1500g sodium hydroxide aqueous solution (4 w / w %), flow rate: m / h 4, contact time: minute: 60; then wash with pure water until neutral, flow rate: m / h h 15, time: minute: about 30; then wash the resin with 1500g hydrochloric acid aqueous solution (4 w / w %), flow rate: m / h 4, contact time: minute: 60; then wash with pure water until neutral, flow rate: m / h 15, time: minute: about 30; repeat washing like this for 3 luns, wash off the impurities in the new resin, and use sodium hydroxide solution for the last time, thus preparing the resin as OH - Form pillars.

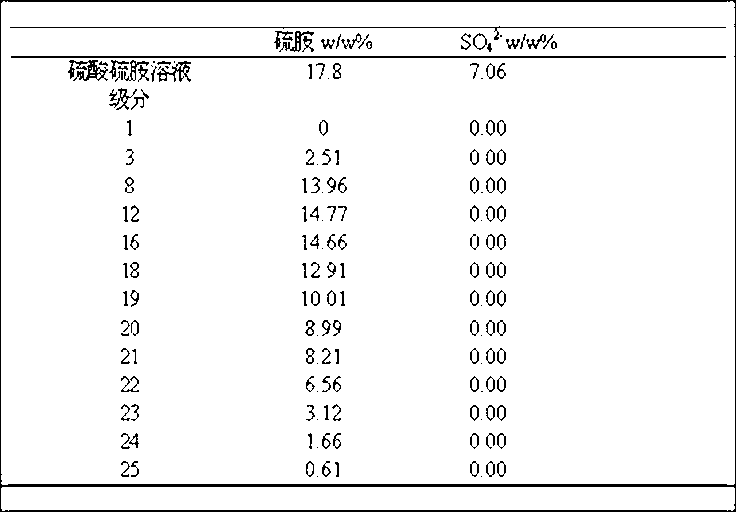

[0031] Use hydrochloric acid to adjust 2000ml of thiamine sulfate aqueous solution (sulfate root 7.06w / w%, thiamine 17.8w / w%) to adjust pH=1.5, then load it on the column at a flow rate of 3.45ml, and collect at a flow rate of 400ml / h The eluent, counted as 100ml each time, was collected 21 times afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com