Patents

Literature

33 results about "Thiamine mononitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiamine mononitrate is a stable nitrate salt form of thiamine. It occurs as a white crystalline powder and is prepared from thiamine hydrochloride. It is used as a food or nutritional supplement and is the preferred form of the vitamin for food fortification. Thiamin mononitrate is used in the pharmaceutical industry to treat beriberi and general malnutrition or malabsorption. Thiamine can be found naturally in foods like grains, yeast, molasses, pork and animal organ meats. Dairy, eggs and legumes have smaller amounts. Though thiamine is found naturally in foods, thiamine mononitrate is not. Thiamine mononitrate is synthesized by removing a chloride ion from thiamin hydrochloride and mixing the final product with nitric acid. Thiamine hydrochloride is hygroscopic whereas the mononitrate has almost no hygroscopic properties. For this reason, the mononitrate is the more stable form of the vitamin in fortified flours and cereals. Thiamine mononitrate is also specifically known as mononitrate de thiamine, nitrate de thiamine, and thiamine nitrate.

Multiple antioxidant micronutrients

A method for administering an antioxidant composition to humans according to their age and sex is disclosed wherein the method comprises administering to said humans a daily dose of a multiple antioxidant micronutrient composition comprising vitamin A (palmitate), beta carotene (from natural d. salina), vitamin C (calcium ascorbate), vitamin D-3 (cholecalciferol), natural source vitamin E including both d-alpha tocopheryl and d-alpha tocopheryl acid succinate, thiamine mononitrate, riboflavin, niacinamide ascorbate, d-calcium pantothenate, pyridoxine hydrochloride, cyanocobalamin, folic acid (folacin), d-biotin, selenium (1-seleno methionine), chromium picolinate, zinc glycinate, calcium citrate, and magnesium citrate. For persons over the age of about 51, the composition preferably further comprises one or more of co-enzyme Q10, N-acetyl cysteine, and alpha lipoic acid. Preferably, also, vitamin D is added for women over the age of about 36.

Owner:NEW AGE HEALTH SCI INC

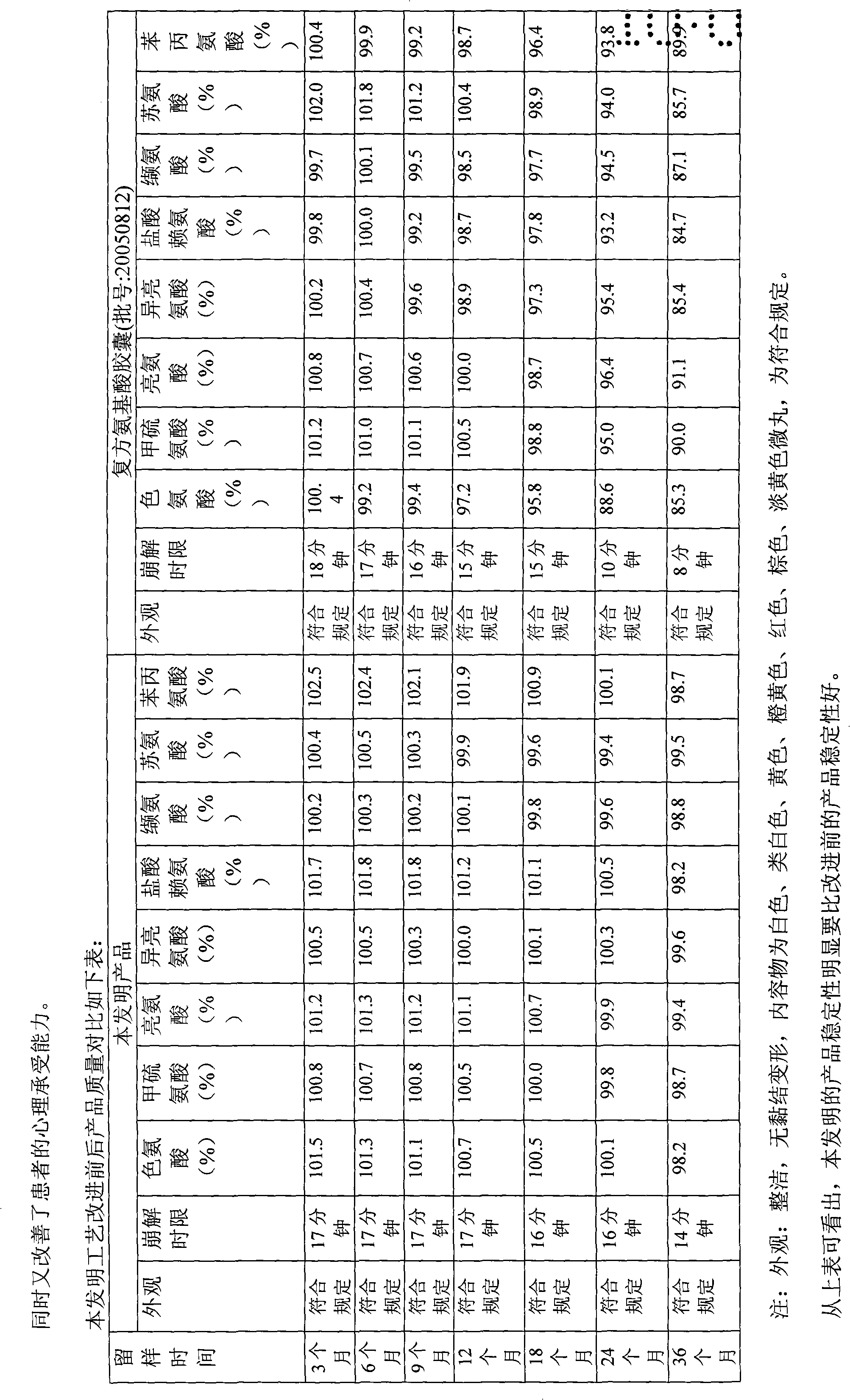

8-amino acid/11-vitamin containing micro granule capsule and preparation method thereof

ActiveCN101773512AImprove bioavailabilityUnique craftPeptide/protein ingredientsHydroxy compound active ingredientsDiseaseLiver and kidney

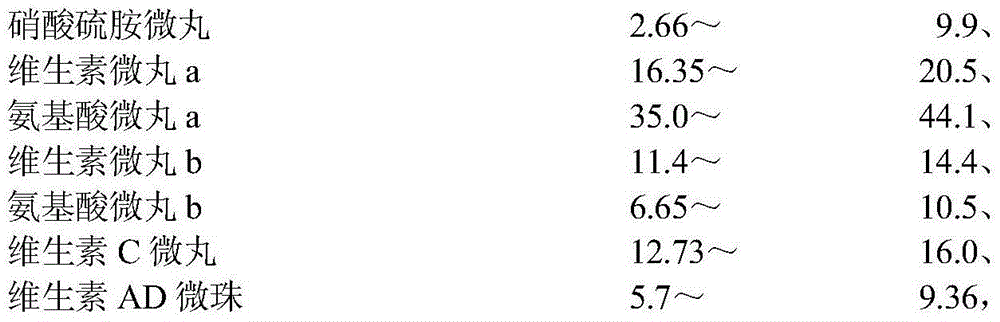

The invention discloses an 8-amino acid / 11-vitamin containing micro granule capsule and a preparation method thereof, wherein the micro granule capsule contains 7 ball micro granules consisting of the following raw materials in part by weight: 2.66-9.9 parts of thiamine mononitrate micro granule, 16.35-20.5 parts of vitamin micro granule a, 35.0-44.1 parts of amino acid micro granule a, 11.4-14.4 parts of vitamin micro granule b, 6.65-10.5 parts of amino acid micro granule b, 12.73-16.0 parts of vitamin C micro granule and 5.7-9.36 parts of vitamin AD micro bead. The method has the advantages of scientific and reasonable proportion, good stability of products, no toxicity and side effect and excellent biological effect, and can be used for the preparation of medicines treating chronic liver and kidney diseases and of food alleviating and eliminating physical fatigue caused by sports training.

Owner:SHENZHEN WANHE PHARMA

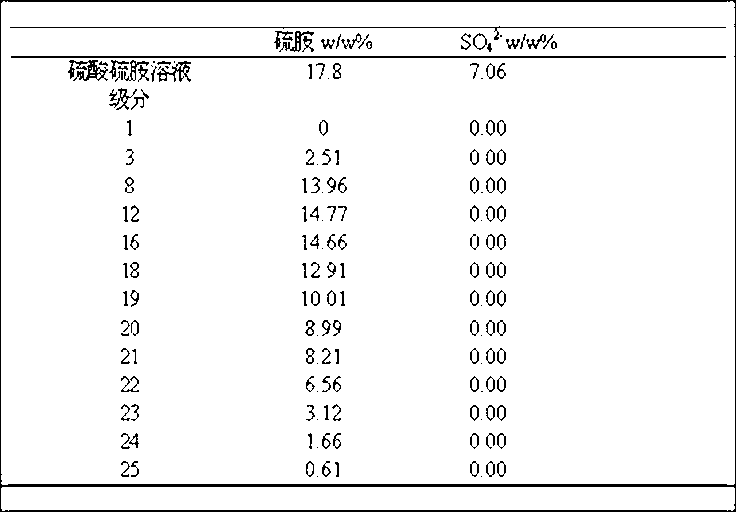

Novel method for synthesizing vitamin B1 hydrochloride

InactiveCN102952126AReduce usageSimple production processOrganic chemistryChlorosulfuric acidSulfate radicals

The invention provides a novel method for synthesizing a vitamin B1 hydrochloride. The method comprises the following steps of: treating a vitamin B1 sulfate aqueous solution by adopting an ion exchange resin; removing sulfate radicals; and concentrating and crystalizing to prepare the vitamin B1 hydrochloride. Due to the adoption of the method, the conventional process for producing a vitamin B1 hydrochloride by transforming from thiamine mononitrate is eliminated, residues of an organic solvent in a product are avoided since an organic solvent is not adopted, a process for preparing acid methanol from hydrochloric acid gas by using chlorosulfonic acid is eliminated simultaneously, and environmental pollution is lowered.

Owner:HUAZHONG PHARMA

Multiple antioxidant micronutrients

A method for optimizing the health of humans according to their age and sex is disclosed wherein the method comprises administering to said humans a daily dose of a multiple antioxidant micronutrient composition comprising vitamin A (palmitate), beta-carotene (from natural d. salina), vitamin C (calcium ascorbate), vitamin D-3 (cholecalciferol), natural source vitamin E including both d-alpha tocopherol and d-alpha tocopheryl acid succinate, thiamine mononitrate, riboflavin, niacinamide ascorbate, d-calcium pantothenate, pyridoxine hydrochloride, cyanocobalamin, folic acid (folacin), d-biotin, selenium (l-seleno methionine), chromium picolinate, zinc glycinate, calcium citrate, and magnesium citrate. For persons over the age of about 51, the composition preferably further comprises one or more of co-enzyme Q10, N-acetyl cysteine, and alpha lipoic acid. Preferably, also, vitamin D is added for women over the age of about 36.

Owner:NEW AGE HEALTH SCI INC

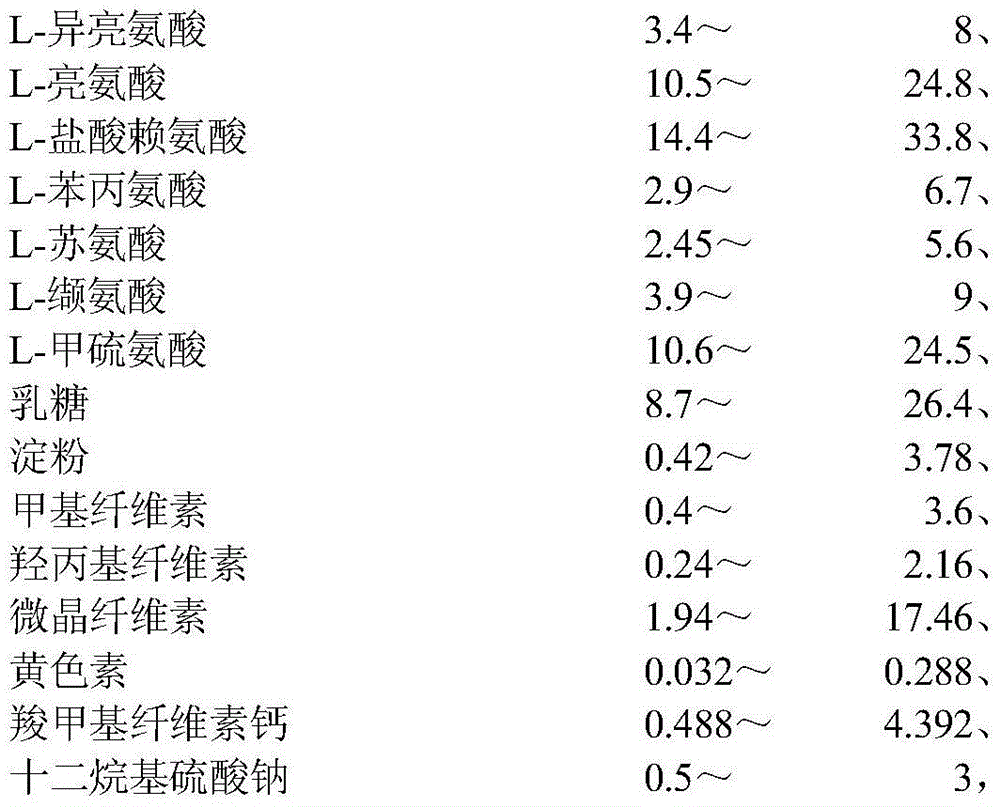

Compound amino acid capsule including eight amino acids and eleven vitamins

ActiveCN103142633AImprove bioavailabilityUnique craftHydroxy compound active ingredientsPeptide/protein ingredientsThiamineVitamin C

The invention relates to a compound amino acid capsule (8-11) and a preparation method thereof, specifically to a capsule including pellets of eight amino acids and eleven vitamins and a preparation method thereof. The capsule comprises 7 spherical pellets which are composed of the following raw materials by weight: 2.66 to 9.9 parts of a thiamine mononitrate pellet, 16.35 to 20.5 parts of a vitamin pellet a, 35.0 to 44.1 parts of an amino acid pellet a, 11.4 to 14.4 parts of a vitamin pellet b, 6.65 to 10.5 parts of an amino acid pellet b, 12. 73 to 16.0 parts of a vitamin C pellet and 5.7 to 9.36 parts of a vitamin AD bead. The capsule provided by the invention has the advantages of a scientific and reasonable ratio, good stability, no toxic and side effects, high security and good biological effects and can be applied in preparation of medicines used for treating chronic liver and kidney diseases and of foodstuffs used for alleviating and eliminating physical fatigue caused by exercise training. The capsule provided by the invention has characteristics superior to those of the prior art.

Owner:SHENZHEN WANHE PHARMA

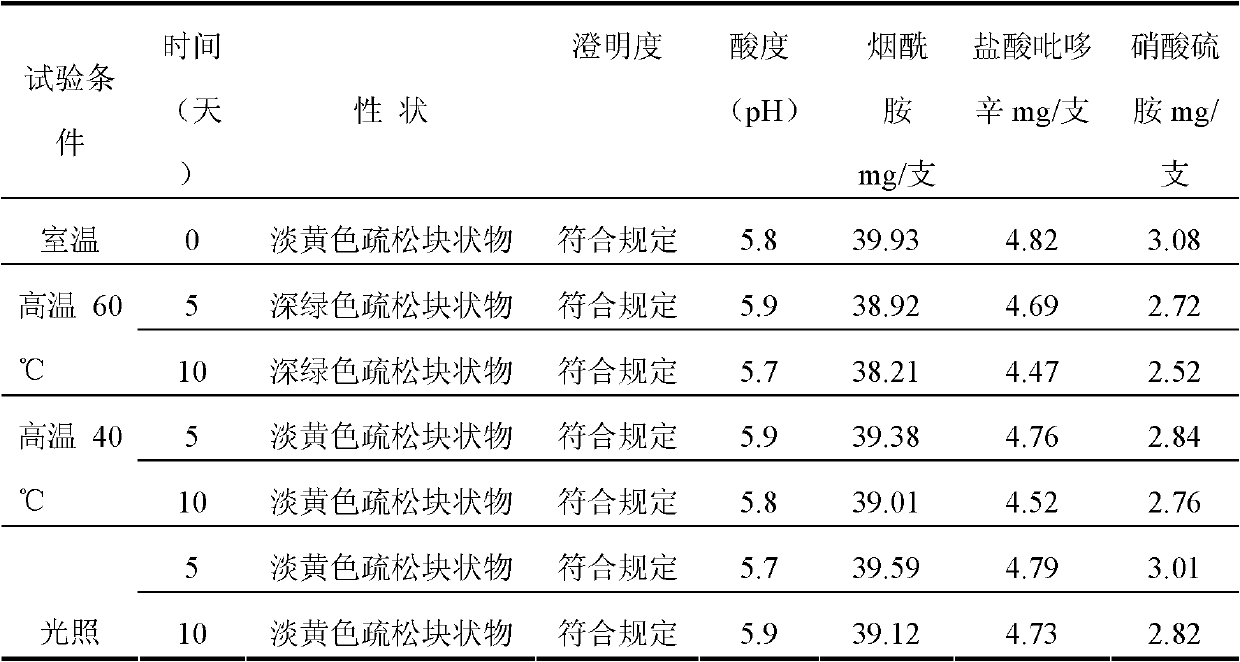

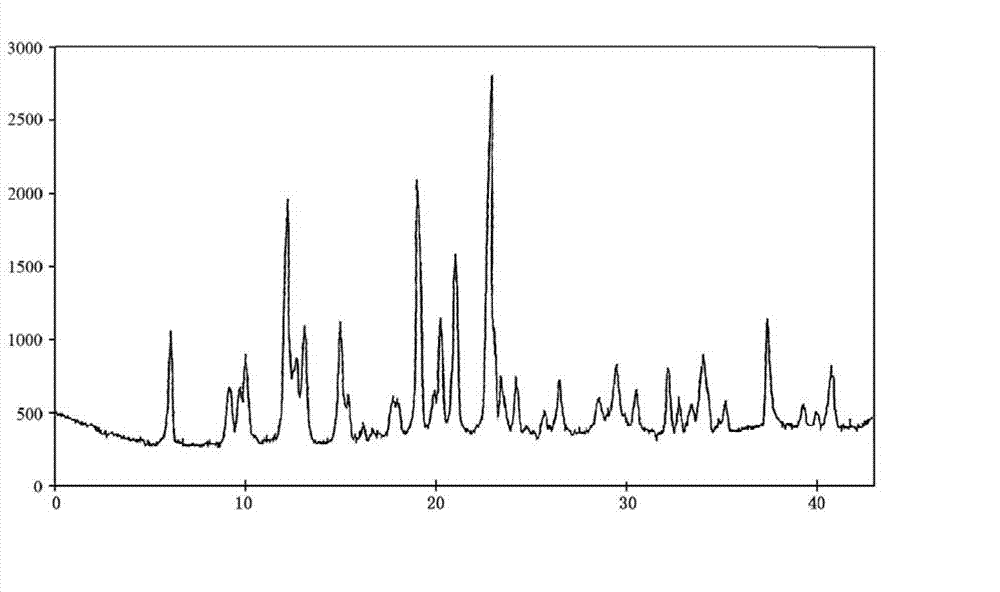

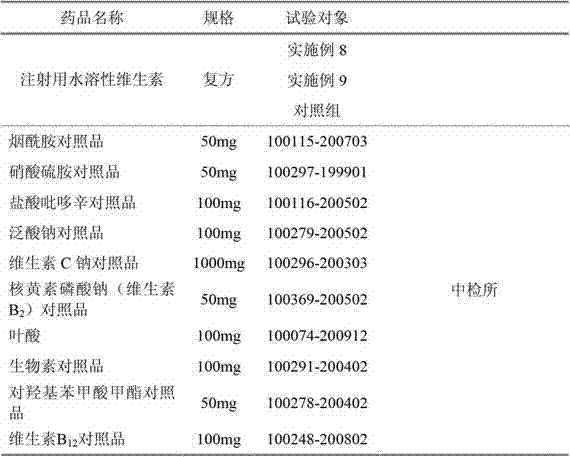

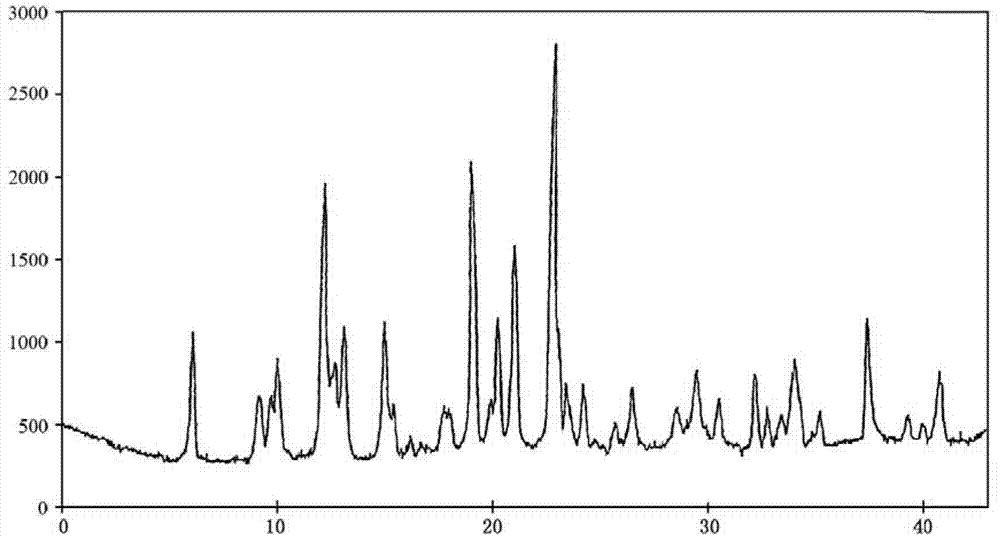

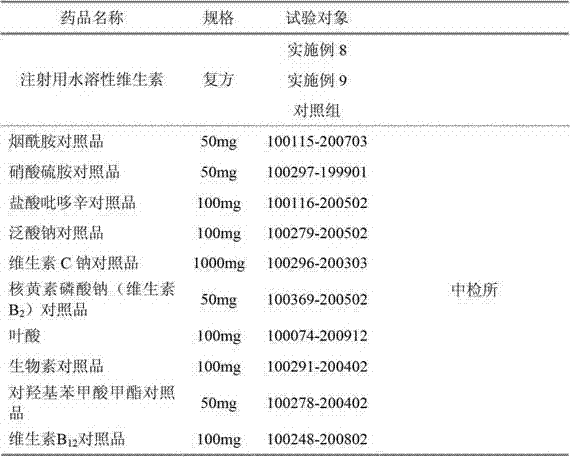

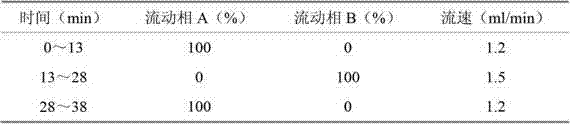

Water-soluble vitamin composition freeze-drying preparation for injection

ActiveCN101904862AGranularity adjustableConcentrated particle size distributionPowder deliveryMetabolism disorderFreeze-dryingSodium pantothenate

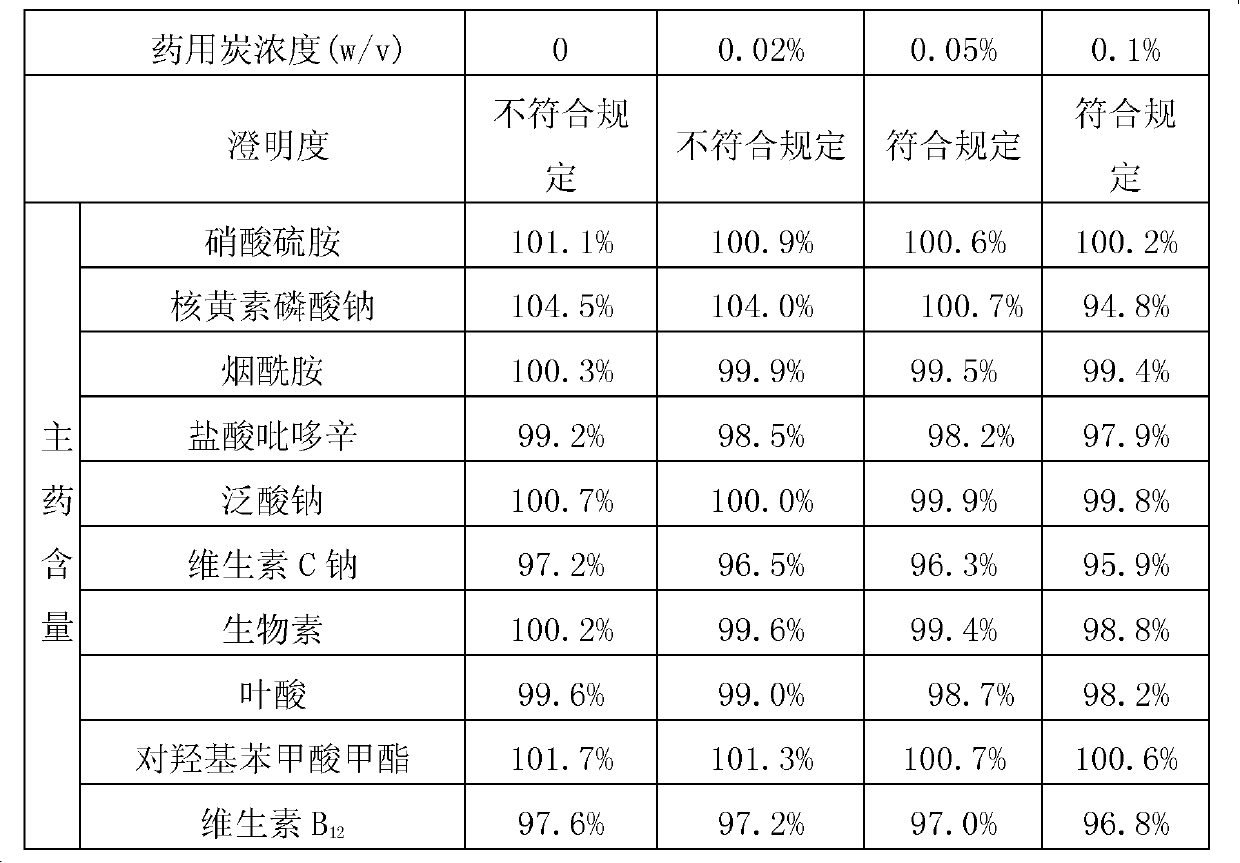

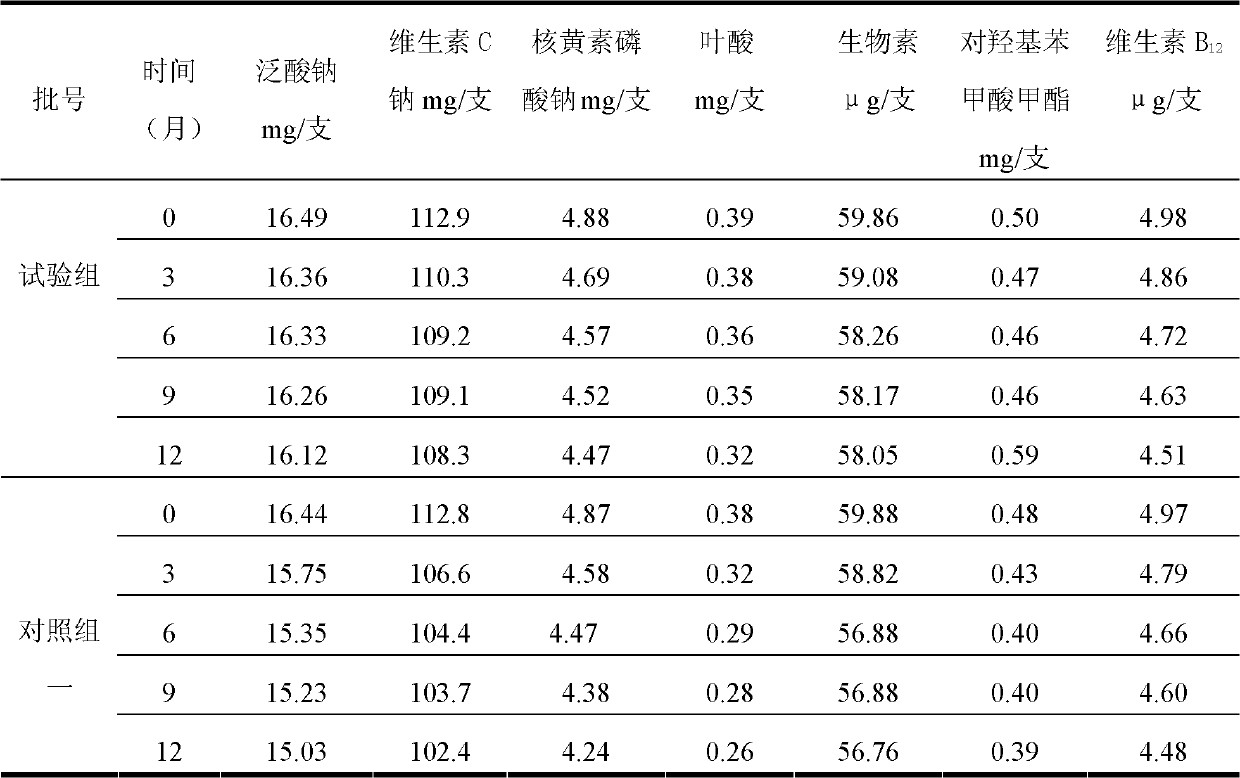

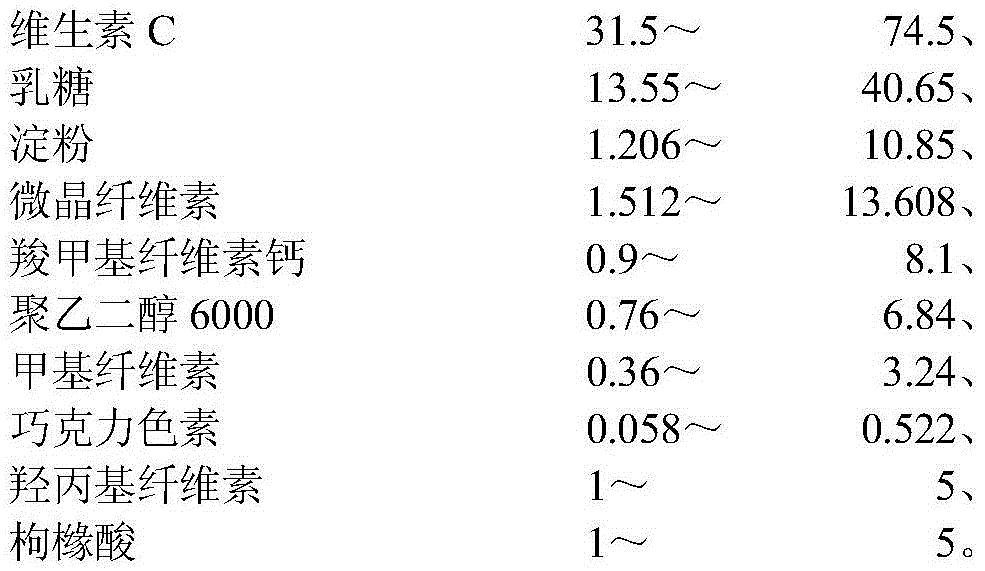

The invention discloses a water-soluble vitamin composition freeze-drying preparation for injection. The freeze-drying preparation comprises the following raw materials and is prepared into 1,000 bottles: 2.8 to 3.4 grams of thiamine mononitrate, 36 to 44 grams of nicotinamide, 4.4 to 5.4 grams of pyridoxine hydrochloride, 14.8 to 18.1 grams of sodium pantothenate, 4.4 to 5.4 grams of riboflavin sodium phosphate, 102 to 124 grams of sodium vitamin C, 54 to 66 milligrams of biotin, 0.36 to 0.44 gram of folic acid, 124.5 to 6.0 milligrams of vitamin B, and 0.4 to 0.6 gram of methyl-p-hydroxy benzoate, wherein the nicotinamide is nicotinamide hydrate, and the sodium pantothenate is sodium pantothenate hydrate. The water-soluble vitamin for injection has adjustable grain size, concentrated grain size distribution, glabrous surface, high product fluidity, greatly improved stability and high dissolution rate, and a preparation process of the preparation is simple and is favorable for popularization and use.

Owner:SHANDONG YUXIN PHARMA CO LTD

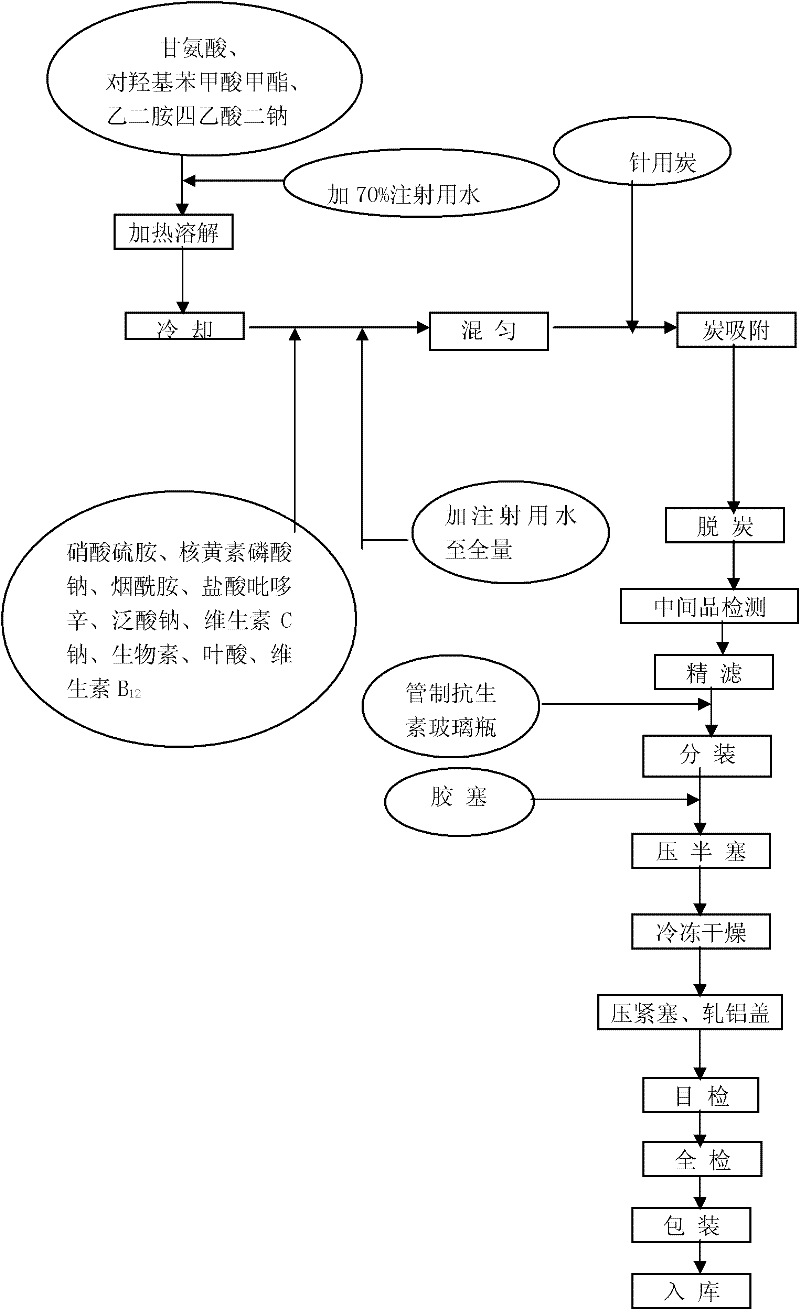

Water-soluble vitamin freeze-dried preparation for injection and preparation method thereof

ActiveCN103110656AImprove stabilityGuarantee drug safetyPowder deliveryMetabolism disorderFreeze-dryingSodium ascorbate

The invention discloses a water-soluble vitamin freeze-dried preparation for injection. 1000 bottles of freeze-dried preparations are prepared from the following raw materials: 2.8-3.4g of thiamine mononitrate, 36-44g of nicotinamide, 4.4-5.4g of pyridoxine hydrochloride, 14.8-18.1g of sodium pantothenate compound, 4.4-5.4g of riboflavin sodium phosphate, 102-124g of sodium ascorbate, 54-66mg of biotin, 0.36-0.44g of folic acid, 4.5-6.0mg of vitamin B12, 0.4-0.6g of methyl p-hydroxybenzoate, 280-320g of glycine, 0.4-0.6g of ethylene diamine tetraacetic acid disodium salt and 2000-3000ml of water for injection. The stability of existing sodium pantothenate is obviously improved by the obtained sodium pantothenate compound, thus ensuring that the sodium pantothenate containing water-soluble vitamin freeze-dried preparation for injection has ideal stability and curative effect and further ensuring medication safety of the patients.

Owner:SHANXI PUDE PHARMA CO LTD

8-amino acid/11-vitamin containing micro granule capsule and preparation method thereof

ActiveCN101773512BImprove bioavailabilityUnique craftPeptide/protein ingredientsHydroxy compound active ingredientsDiseaseLiver and kidney

The invention discloses an 8-amino acid / 11-vitamin containing micro granule capsule and a preparation method thereof, wherein the micro granule capsule contains 7 ball micro granules consisting of the following raw materials in part by weight: 2.66-9.9 parts of thiamine mononitrate micro granule, 16.35-20.5 parts of vitamin micro granule a, 35.0-44.1 parts of amino acid micro granule a, 11.4-14.4parts of vitamin micro granule b, 6.65-10.5 parts of amino acid micro granule b, 12.73-16.0 parts of vitamin C micro granule and 5.7-9.36 parts of vitamin AD micro bead. The method has the advantages of scientific and reasonable proportion, good stability of products, no toxicity and side effect and excellent biological effect, and can be used for the preparation of medicines treating chronic liver and kidney diseases and of food alleviating and eliminating physical fatigue caused by sports training.

Owner:SHENZHEN WANHE PHARMA

Micronutrient formulations for radiation applications

A radioactive protection micronutrient formulation system is provided and the system comprises: a formulation consisting essentially of antioxidants, the antioxidants are selected from the group consisting essentially of vitamin C, vitamin E, N-acetyl cysteine, natural mixed carotenoids, and alpha-lipoic acid, vitamin A (palmitate), vitamin D-3 (cholecalciferol), thiamine mononitrate, riboflavin, niacinamide ascorbate, d-calcium pantothenate, pyridoxine hydrochloride, cyanocobalamin, folic acid, D-Biotin, selenium (1-seleno-methionine), chromium picolinate, zinc glycinate, calcium citrate and magnesium citrate and mixtures thereof; and plus a booster formulation selected from a group consisting essentially of vitamin C, d-alpha tocopheryl acid succinate, alpha tocopherol, N-acetyl cysteine, natural mixed carotenoids and alpha lipoic acid, the formulation is designed to reduce the risk in humans exposed to doses of ionizing radiation of becoming subjected to at least one condition selected from the group consisting essentially of radiation-induced acute leukemia, breast cancer, thyroid cancer and other somatic and heritable mutations.

Owner:NEW AGE HEALTH SCI INC

Concentrated feed for pigs and preparation method thereof

The invention discloses a concentrated feed for pigs. The concentrated feed for pigs is prepared from the following raw materials in parts by weight: 3-4 parts of calcium dihydrogen phosphate, 0.5-0.6 part of zinc sulfate, 0.03-0.05 part of riboflavin, 0.3-0.5 part of thiamine mononitrate, 2-4 parts of sodium chloride, 270-300 parts of bean pulp, 10-14 parts of lychee exocarp, 1-2 parts of prepared rehmannia roots, 40-50 parts of palm kernel meal, 3-5 parts of dregs of fat, 28-30 parts of a chelated emulsion, 10-13 parts of barley vinegar residues, 1-2 parts of sodium hydrogen sulfite, 30-40 parts of potato slurry residue and 0.1-0.2 part of tocopheryl acetate. Trace elements added into the concentrated feed are less than that in a conventional feed, so that the cost is low; however, the feed still can meet the demand on normal growth and development of pigs.

Owner:安徽喜乐佳生物科技有限公司

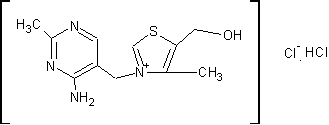

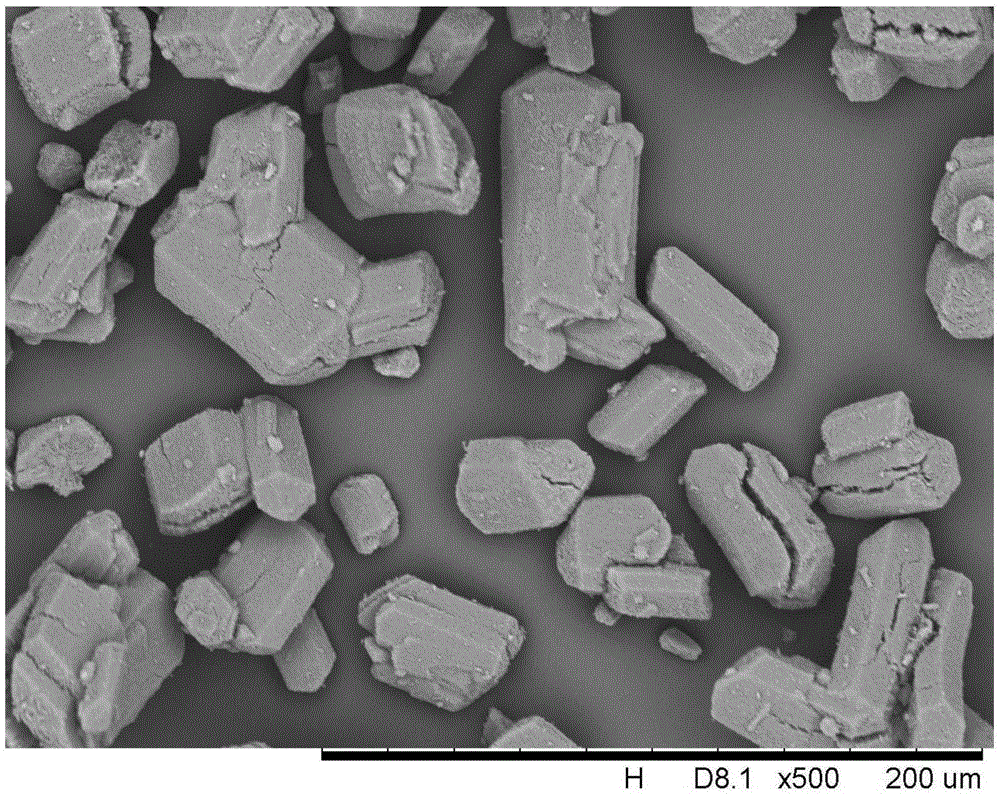

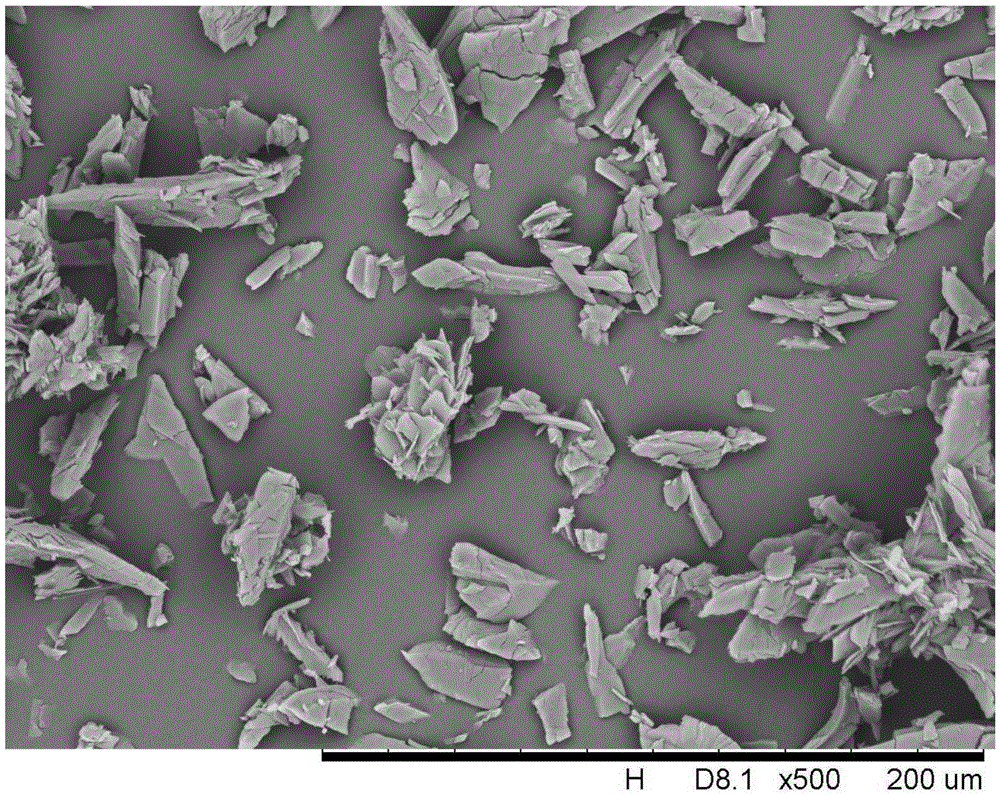

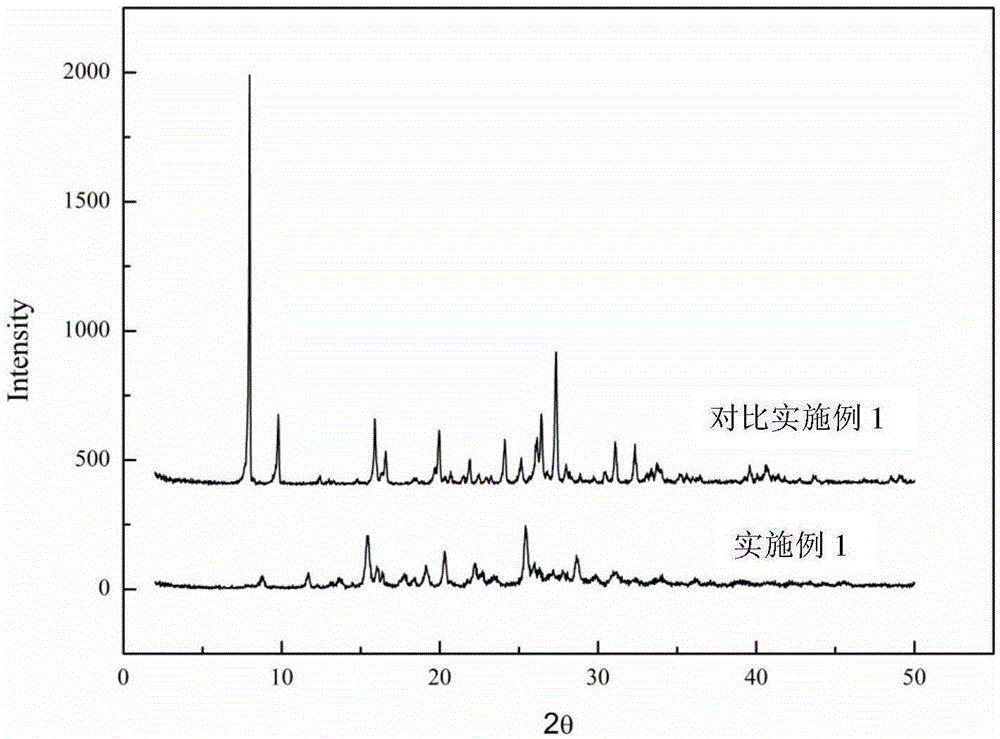

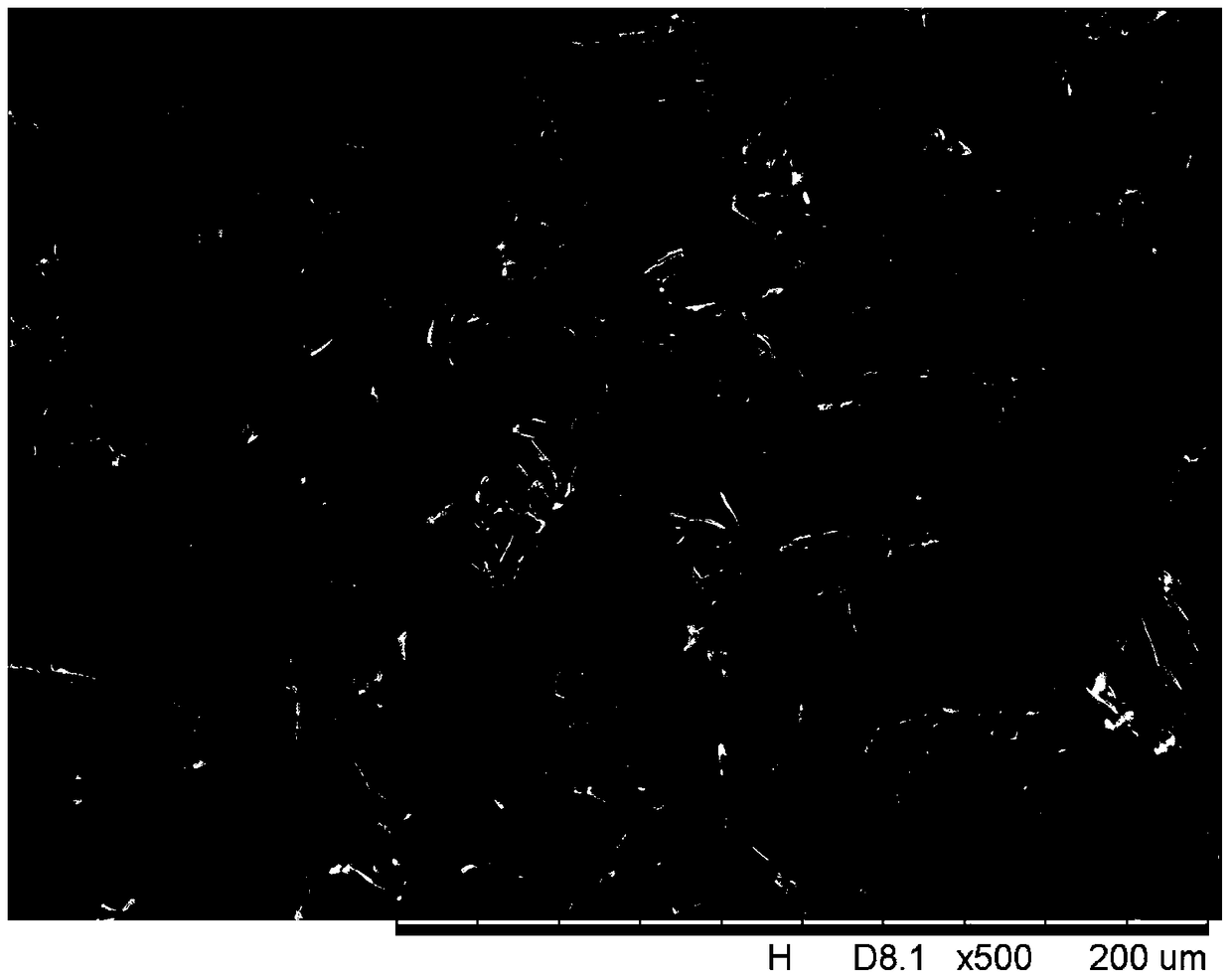

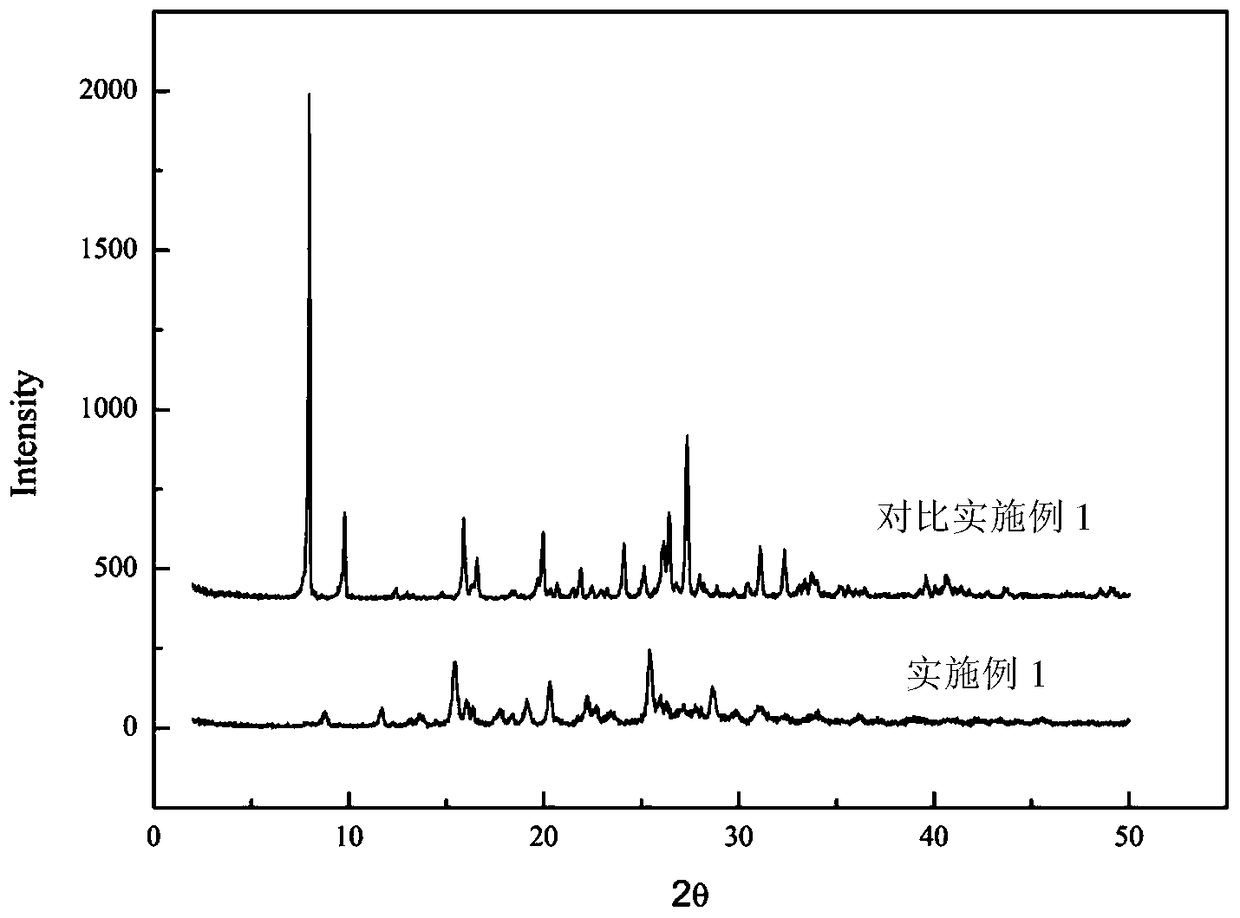

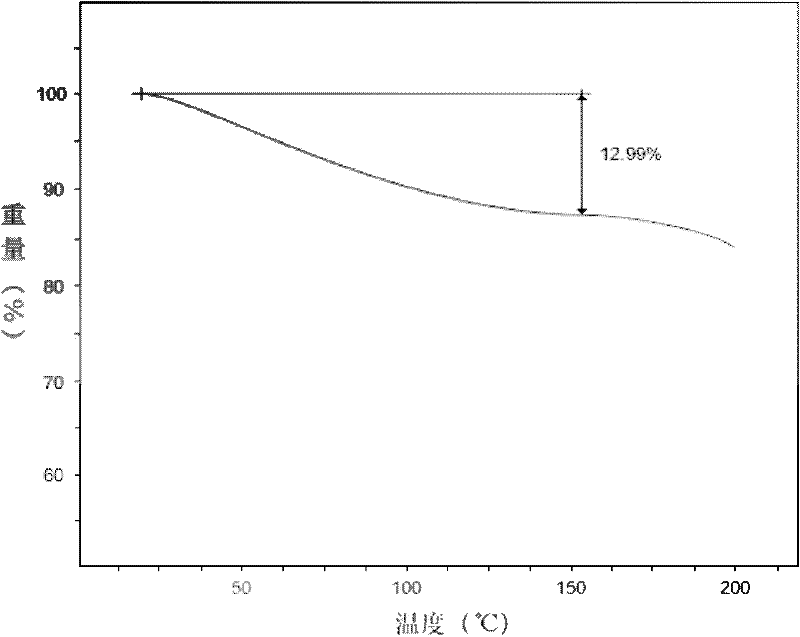

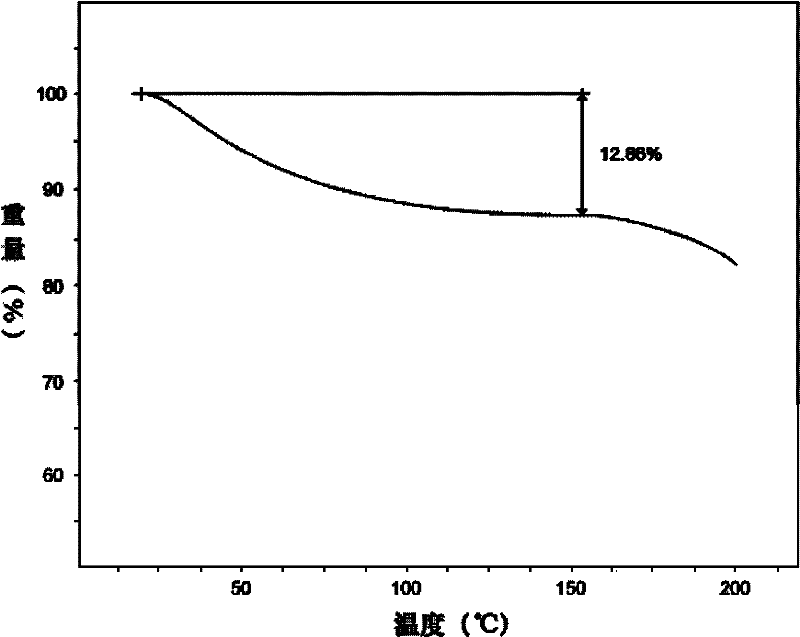

Method for preparing thiamine hydrochloride crystal product

ActiveCN105315272AComply with subsequent preparation process requirementsResidue reductionOrganic chemistry methodsSolventThiamine mononitrate

The invention discloses a method for preparing a thiamine hydrochloride crystal product. Thiamine mononitrate is dispersed into a solvent, and thiamine mononitrate turbid liquid with the concentration of 0.05 g / ml to 0.2 g / ml is obtained, and heated to 50 DEG C to 70 DEG. Chlorosulfonic acid is dropwise added to concentrated hydrochloric acid to generate hydrogen chloride gas, and the gas is introduced into to concentrated sulfuric acid to be dried, and is introduced into the thiamine mononitrate turbid liquid under stirring action. After introduction of the hydrogen chloride gas is completed, heat preservation is carried out for 15 min to 30 min, then the temperature is reduced to 10 DEG C, the cooling rate ranges from 0.1 DEG C / min to 0.5 DEG C / min, filtering, washing and drying are carried out, and then thiamine hydrochloride crystals are prepared. The crystals are rhabdolith, the angle of repose ranges from 31 DEG C to 36.4 DEG C, and the bulk density ranges from 0.50 g / ml to 0.608 g / ml. The thiamine hydrochloride crystal product is good in liquidity. According to the method, the process that thiamine hydrochloride methyl alcohol solvent compounds are formed firstly, then drying is carried out to remove methyl alcohol is avoided, and therefore environmental pollution is reduced, and cost and solvent residues are reduced. The method can be suitable for large-scale production.

Owner:TIANJIN UNIV +1

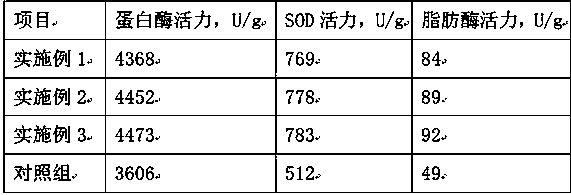

Banana peel enzyme fermentation method

The invention discloses a banana peel enzyme fermentation method. The banana peel enzyme fermentation method comprises the following steps: (1) cleaning the banana peels, chopping, soaking in a soaking solution for 3 to 4 hours, filtering, and performing the composite enzyme enzymolysis for the banana peel residues; (2) sterilizing the enzymolyzed banana peel residues, inoculating an activated strain, fermenting for 3 to 4 days, and obtaining a banana peel fermentation solution; and (3) uniformly mixing the banana peel fermentation solution, alpha-arbutin, thiamine mononitrate and disodium creatine phosphate, adding into a vacuum freeze drying machine, drying until the water content is less than 5 percent, and obtaining enzyme powder. The prepared banana peel enzyme is fresh in aroma, hasfermentation fragrance, pure acidic taste, looseness and gloss; and compared with the enzyme products on the market, the protease activity, the SOD activity and the lipase content in the prepared banana peel enzyme powder are significantly improved, probiotics in the product is efficiently reserved, and the product quality can be improved.

Owner:安徽衣露士生物科技有限公司

Crystallization method of thiamine mononitrate

InactiveCN106588907AReduce cumbersomeLittle production costOrganic chemistryThiamine mononitrateAmmonium nitrate

The invention relates to an improvement in a crystallization method of thiamine mononitrate. A traditional method comprises the following steps: mixing a crude nitric acid B1, namely, thiamine sulfate solution with an ammonium nitrate aqueous solution in a matched amount, then adding 20%-25% ammonia dropwise until the PH of the mixture reaches 7.2 to 7.5, performing cooling, and separating the solid-liquid mixture to obtain crystals of nitric acid B1. The invention relates to the improvement in the crystallization method of thiamine mononitrate, the mixing sequence and the proportion of three solutions (the thiamine sulfate solution, the ammonium nitrate solution and ammonia) are adjusted, the three solutions are mixed simultaneously, and accordingly, the crystal form of thiamine mononitrate is changed with adoption of the crystallization method. The crystallization method of thiamine mononitrate is improved to replace a traditional crystallization process, the crystal form of a product is changed from the original needle shape into a rod or ball shape, the product particles become larger, the bulk density increases, the packaging volume decreases, and great benefit is provided for reducing the transportation cost and the operating cost and improving the market competitiveness of the product.

Owner:HUAZHONG PHARMA

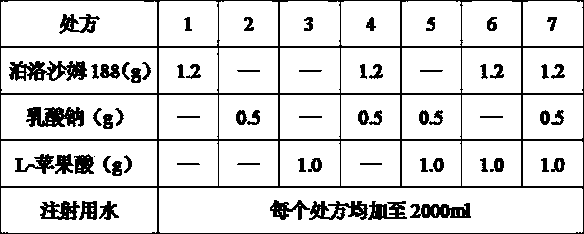

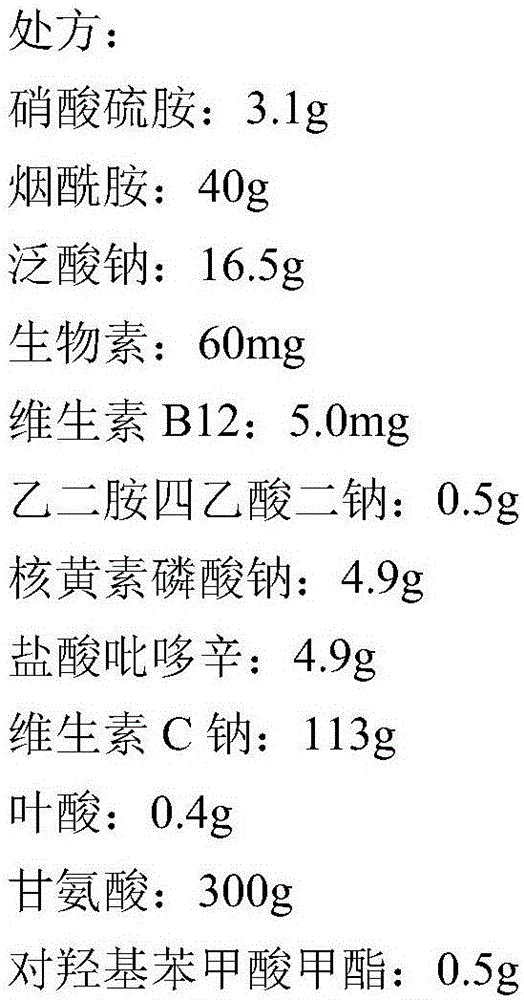

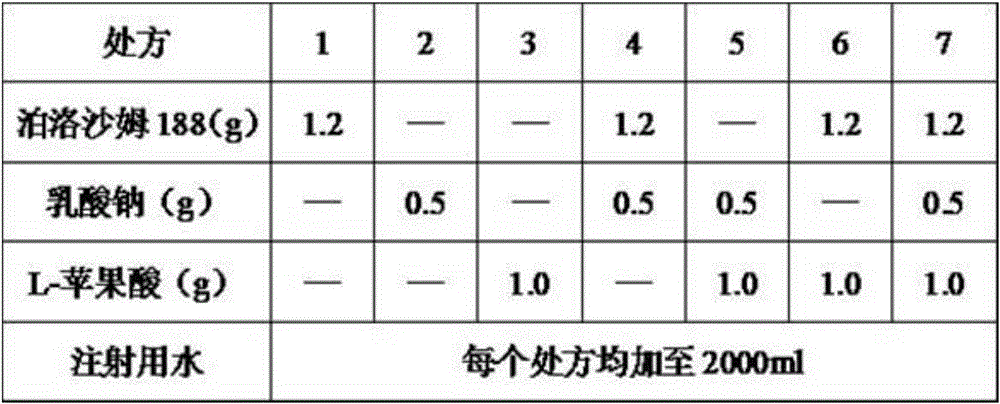

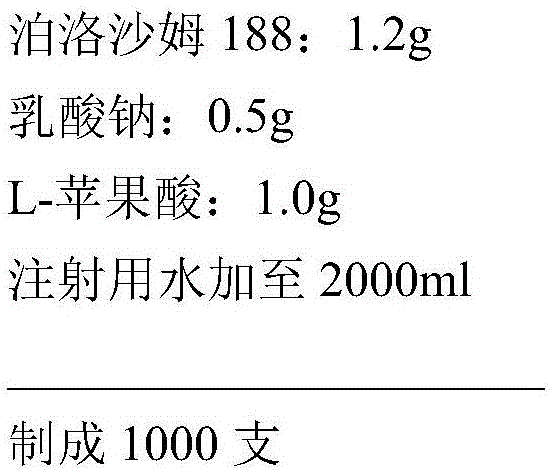

Water-soluble vitamin pharmaceutical composition for injection

ActiveCN104382865AQuality assuranceImprove efficiencyPowder deliveryMetabolism disorderBenzoic acidSodium lactate

The invention relates to a water-soluble vitamin pharmaceutical composition for injection. The water-soluble vitamin pharmaceutical composition for injection is prepared from 3.1g of thiamine mononitrate, 40g of nicotinamide, 16.5g of sodium pantothenate, 60mg of biotin, 5.0mg of vitamin B12, 0.5g of disodium ethylene diamine tetraacetate, 4.9g of riboflavin sodium phosphate, 4.9g of pyridoxine hydrochloride, 113g of sodium vitamin C, 0.4g of folic acid, 300g of glycine, 0.5g of methyl parahydroxybenzoate, 1.2g of poloxamer 188, 0.5g of sodium lactate, 1.0g of L-malic acid and water for injection, wherein the water for injection is added until the total volume is 2000ml. The water-soluble vitamin pharmaceutical composition for injection, disclosed by the invention, is good in stability and greatly improved in medication safety.

Owner:湖北美林药业有限公司

Method and composition for inhibiting aged skin

ActiveUS20180318184A1Accelerate effective transdermal deliveryOptimize allocationCosmetic preparationsHeavy metal active ingredientsGlucose uptakeSkin cell

A method and composition for inhibiting aged skin by topically applying to human skin a topical anti-aging composition. The method involves applying the human skin of afflicted area with an effective amount of the anti-aging composition containing chromium chloride, thiamine mononitrate, magnesium sulfate, and dmae bitartrate for a period of time sufficient to impart the appearance of aged skin. The topical composition is formulated into a pharmaceutically acceptable medium to optimize glucose uptake into the skin cells to properly replace iron production of skin cells, thereby inhibiting the appearance of aged skin.

Owner:RUSS IP HLDG GRP LLC

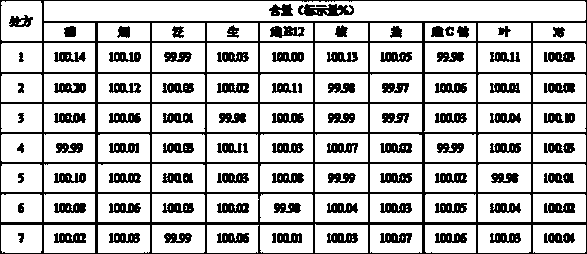

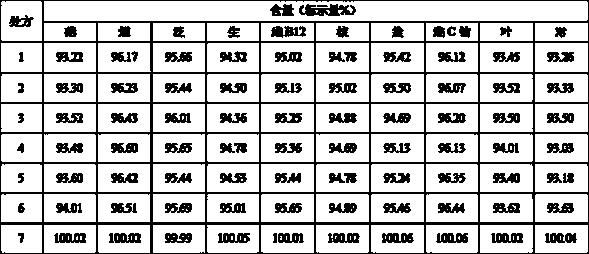

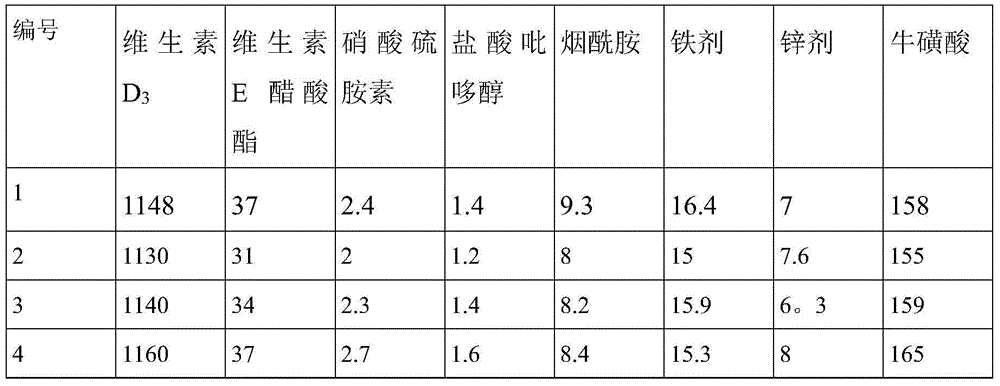

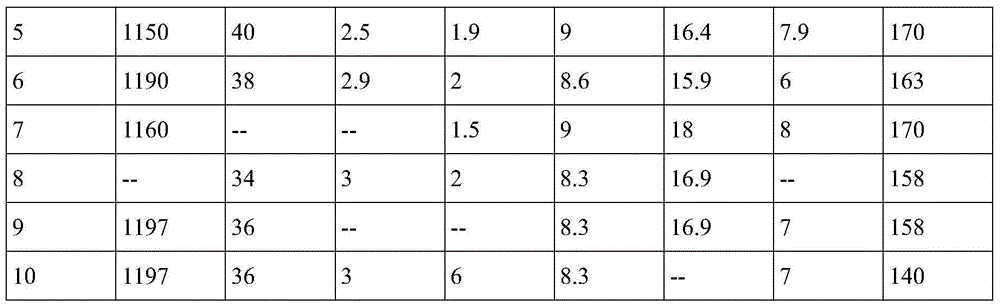

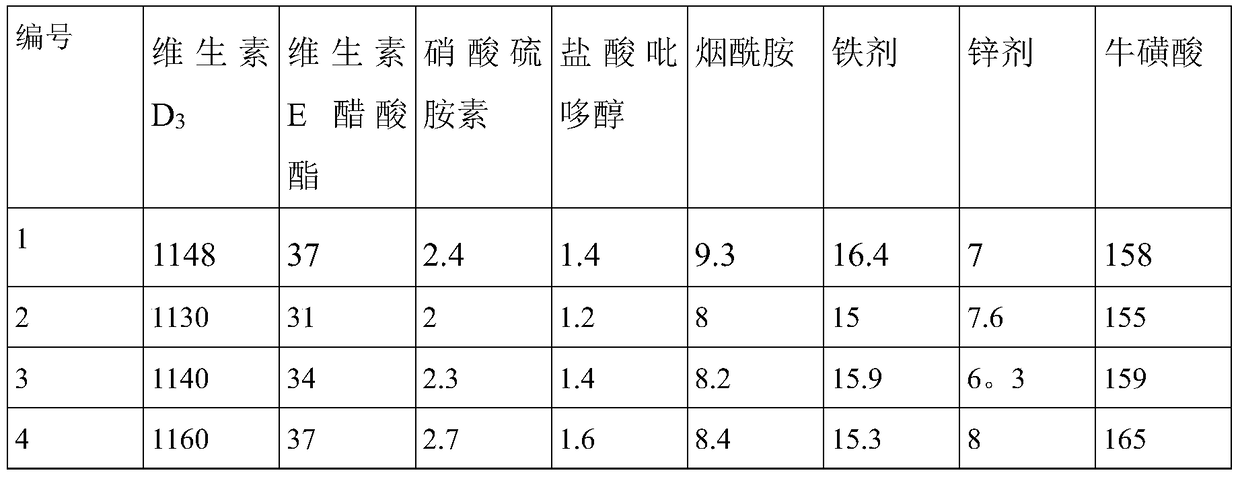

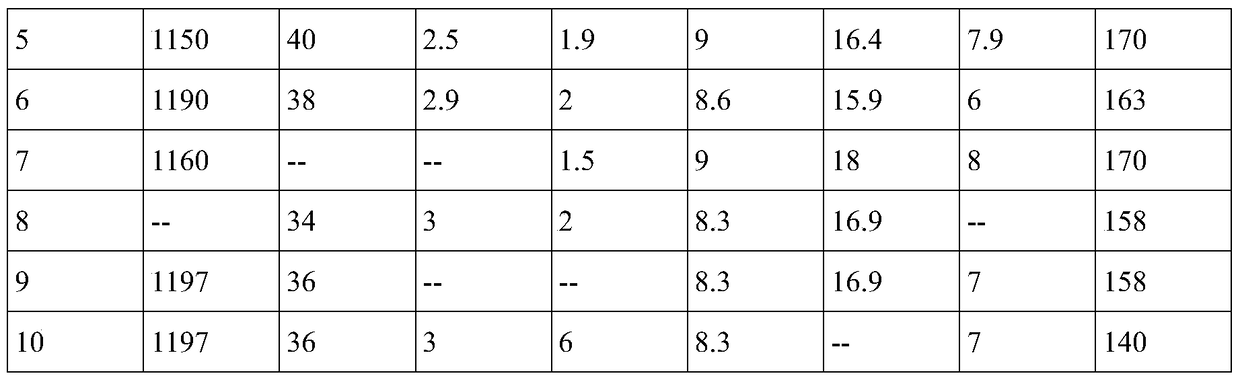

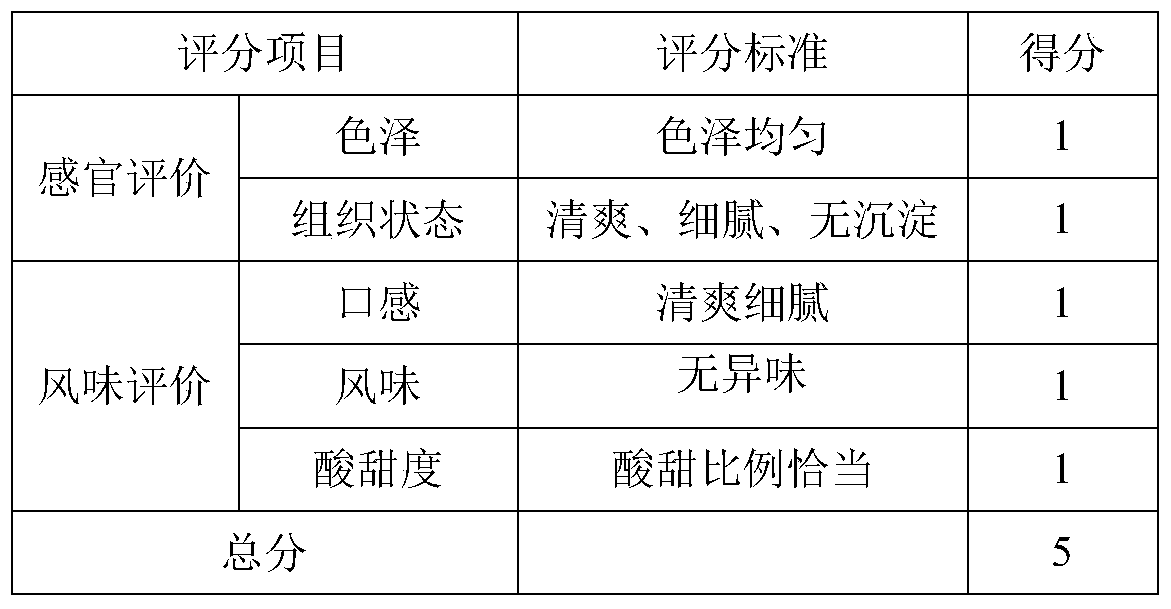

Fermented-type dairy product and preparation method thereof

ActiveCN104642543AEliminate or reduce the impact of stabilityAssisted mobilityMilk preparationVitamin E AcetateThiamine mononitrate

The invention discloses a fermented-type dairy product which includes an exercise functional element comprising: vitamin D3, vitamin E acetate, thiamine mononitrate, pyridoxine hydrochloride, nicotinamide, an iron agent, a zinc agent and taurine. The invention also provides two preparation methods of two different fermented-type dairy products, wherein the preparation methods can be respectively used for preparing a milk beverage and yogurt containing the exercise functional element. When the dairy product is prepared, the exercise functional element, a metal chelating agent and a stabilizing agent are added to the dairy product at a certain ratio, so that the dairy product is reduced in fermentation time and fermentation risk, is improved in production efficiency, is reduced in production cost and is relatively increased in nutritional value. In addition, a large amount of nutrients in fermented milk can be digested and absorbed more easily after exercises, and the fermented-type dairy product is ensured in stability during selling and storing.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

A kind of fermented dairy product and preparation method thereof

The invention discloses a fermented-type dairy product which includes an exercise functional element comprising: vitamin D3, vitamin E acetate, thiamine mononitrate, pyridoxine hydrochloride, nicotinamide, an iron agent, a zinc agent and taurine. The invention also provides two preparation methods of two different fermented-type dairy products, wherein the preparation methods can be respectively used for preparing a milk beverage and yogurt containing the exercise functional element. When the dairy product is prepared, the exercise functional element, a metal chelating agent and a stabilizing agent are added to the dairy product at a certain ratio, so that the dairy product is reduced in fermentation time and fermentation risk, is improved in production efficiency, is reduced in production cost and is relatively increased in nutritional value. In addition, a large amount of nutrients in fermented milk can be digested and absorbed more easily after exercises, and the fermented-type dairy product is ensured in stability during selling and storing.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of enzyme detergent for laboratory ware

InactiveCN106987331AEfficient removalStrong decontaminationOrganic detergent compounding agentsSurface-active detergent compositionsCAPRYLOYL SALICYLIC ACIDThiamine mononitrate

The invention relates to a preparation method of an enzyme detergent for laboratory ware. According to the technical scheme, the enzyme detergent for laboratory ware is prepared by mixing thiamine mononitrate, protease, bifidobacterium infantis, lipid-soluble coenzyme Q10, polyquaternium, bisabolol, seabuckthorn seed oil, green tea essence, AES, probiotics, tocopheryl phosphate, capryloyl salicylic acid, azelaic acid, pyridoxine, okra-seed oil, alkyl polyglucosides(APG0810), enzyme, acetic acid, sweet osmanthus flavor and water.

Owner:CHANGSHA XIEHAOJI BIOENG CO LTD

Preparation method of enzyme cleanser for air conditioners

InactiveCN106987352AEfficient killingFresh airCationic surface-active compoundsOrganic detergent compounding agentsCAPRYLOYL SALICYLIC ACIDPhosphate

The invention discloses a preparation method of an enzyme cleanser for air conditioners. According to the technical scheme, the enzyme cleanser for air conditioners is prepared by mixing thiamine mononitrate, protease, bifidobacterium infantis, oat polypeptide, quaternary ammonium salt, bisabolol, avocado oil, green tea essence, AES, probiotics, tocopherol phosphate, capryloyl salicylic acid, azelaic acid, pyridoxine, Kathon 2, fatty alcohol ether sulfate, enzymes, acetic acid, rose flavor, and water.

Owner:CHANGSHA XIEHAOJI BIOENG CO LTD

Water-soluble vitamin freeze-dried preparation for injection and preparation method thereof

ActiveCN103110656BImprove stabilityShort freeze-drying process timePowder deliveryMetabolism disorderFreeze-dryingSodium ascorbate

Owner:SHANXI PUDE PHARMA CO LTD

A kind of preparation method of thiamine hydrochloride crystal product

ActiveCN105315272BResidue reductionReduce pollutionOrganic chemistry methodsSolventThiamine mononitrate

Owner:TIANJIN UNIV +1

Compound amino acid capsule including eight amino acids and eleven vitamins

ActiveCN103142633BImprove bioavailabilityUnique craftHydroxy compound active ingredientsPeptide/protein ingredientsDiseaseSide effect

The invention relates to a compound amino acid capsule (8-11) and a preparation method thereof, specifically to a capsule including pellets of eight amino acids and eleven vitamins and a preparation method thereof. The capsule comprises 7 spherical pellets which are composed of the following raw materials by weight: 2.66 to 9.9 parts of a thiamine mononitrate pellet, 16.35 to 20.5 parts of a vitamin pellet a, 35.0 to 44.1 parts of an amino acid pellet a, 11.4 to 14.4 parts of a vitamin pellet b, 6.65 to 10.5 parts of an amino acid pellet b, 12. 73 to 16.0 parts of a vitamin C pellet and 5.7 to 9.36 parts of a vitamin AD bead. The capsule provided by the invention has the advantages of a scientific and reasonable ratio, good stability, no toxic and side effects, high security and good biological effects and can be applied in preparation of medicines used for treating chronic liver and kidney diseases and of foodstuffs used for alleviating and eliminating physical fatigue caused by exercise training. The capsule provided by the invention has characteristics superior to those of the prior art.

Owner:SHENZHEN WANHE PHARMA

Vitamin-hormone horticultural product

ActiveUS10836686B1Encourages and improves nutrientEncourages and improves and water uptakeOrganic chemistry methodsNitrogenous fertilisersBiotechnologyPlant roots

A water-suspensible, dry, vitamin-hormone horticultural product for promoting plant root growth comprising a combination of one or more plant growth regulators, mycorrhizae, vitamins B1 and B6, sea kelp and beneficial microbes in a carrier. In one embodiment the product is a dry powder of about 2.00 wt % indole-3-butyric acid in crystalline solid form; about 0.20 wt % thiamine mononitrate (B1) in water-soluble powder form; about 0.20 wt % pyridoxine HCl (B6) in water-soluble powder form; about 2.64 wt % Mycorrhizae in water-soluble powder form; about 1.06 wt % sea kelp extract in brown flake form; about 0.88 wt % Bacillus amyloliquefaciens in water-soluble powder form; about 0.07 wt % sodium lauryl sulfoacetate in water-soluble powder form; and about 92.35 wt % maltodextrin in water-soluble powder form.

Owner:MITOGROW LLC

Water-soluble vitamin composition freeze-drying preparation for injection

ActiveCN101904862BGranularity adjustableConcentrated particle size distributionPowder deliveryMetabolism disorderFreeze-dryingDissolution

The invention discloses a water-soluble vitamin composition freeze-drying preparation for injection. The freeze-drying preparation comprises the following raw materials and is prepared into 1,000 bottles: 2.8 to 3.4 grams of thiamine mononitrate, 36 to 44 grams of nicotinamide, 4.4 to 5.4 grams of pyridoxine hydrochloride, 14.8 to 18.1 grams of sodium pantothenate, 4.4 to 5.4 grams of riboflavin sodium phosphate, 102 to 124 grams of sodium vitamin C, 54 to 66 milligrams of biotin, 0.36 to 0.44 gram of folic acid, 124.5 to 6.0 milligrams of vitamin B, and 0.4 to 0.6 gram of methyl-p-hydroxy benzoate, wherein the nicotinamide is nicotinamide hydrate, and the sodium pantothenate is sodium pantothenate hydrate. The water-soluble vitamin for injection has adjustable grain size, concentrated grain size distribution, glabrous surface, high product fluidity, greatly improved stability and high dissolution rate, and a preparation process of the preparation is simple and is favorable for popularization and use.

Owner:SHANDONG YUXIN PHARMA CO LTD

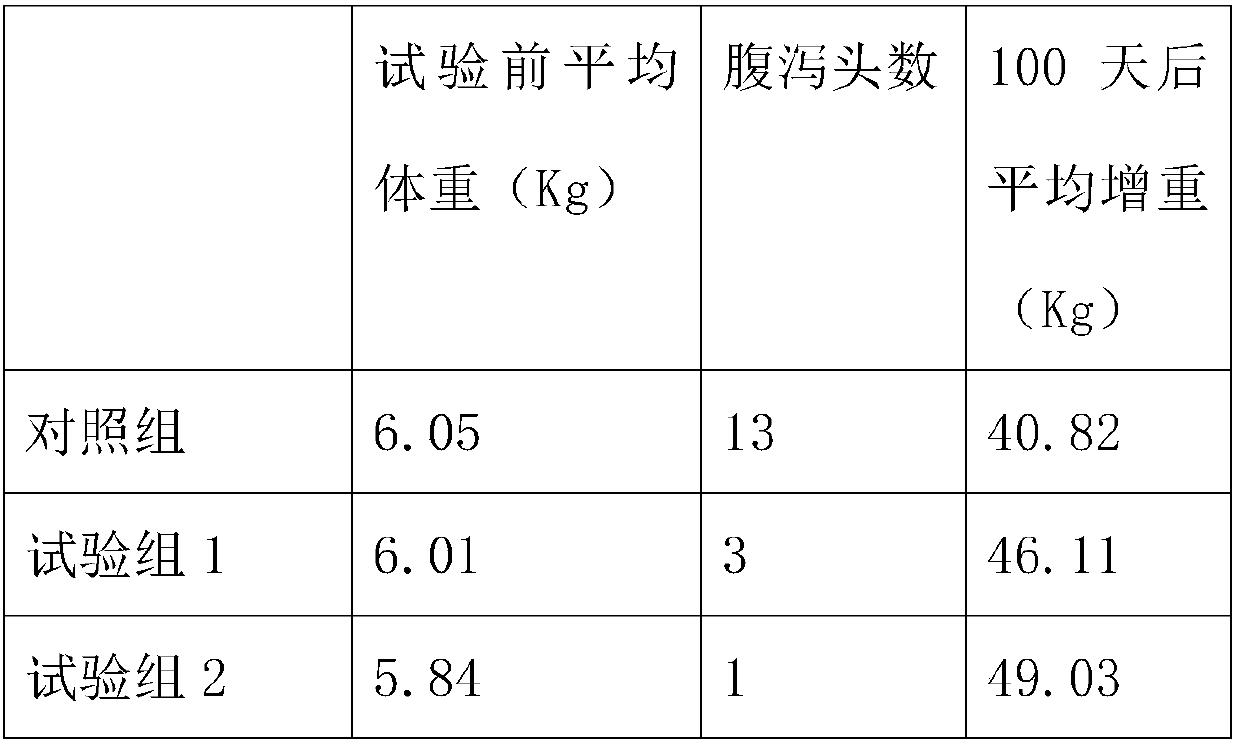

Anti-diarrhea concentrated powder preparation for piglets and preparing method of preparation

InactiveCN107889946AGood for healthIncrease feed intakeFood processingAnimal feeding stuffYeastSulfate

The invention discloses an anti-diarrhea concentrated powder preparation for piglets. The preparation is prepared from, by weight, 10-14 parts of fructus forsythiae, 3-5 parts of cortex phellodendri,12-14 parts of dried tangerine peel, 6-9 parts of radix puerariae, 0.05-0.1 part of zinc sulfate, 0.01-0.03 part of thiamine mononitrate, 5-7 parts of herba portulacae, 10-15 parts of black soybean powder, 1-2 parts of yeast powder, 3-4 parts of glycerinum, 4-6 parts of cactus micro powder, 1-2 parts of ascorbic acid, 0.4-0.5 part of monocalcium phosphate and 3-4 parts of oven earth. The anti-diarrhea concentrated powder preparation is used in cooperation with piglet feed, and the addition amount is 1.5-2%; after the preparation is used, the pig diarrhea rate of the piglets feeding on milk anddairy-product-contained piglet feed is decreased by 80% or above, the health state is remarkably improved, the feed intake of the piglets is effectively improved, the disease incidence is remarkablyreduced, and the survival rate is remarkably increased.

Owner:安庆市柯旷动物药业有限公司

Preparation method of enzyme stove cleaning agent

InactiveCN107012009ARapid emulsification and dissolutionFree from harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEthylic acidCleansing Agents

The invention discloses an enzyme stove cleaning agent. The technical scheme is achieved as follows: the enzyme stove cleaning agent is prepared by mixing thiamine mononitrate, protease, bifidobacterium infantis, tea saponin, ceramide, wheat germ, patchouli oil, green tea flavor, AES, probiotic flora, methylethyl ester, fish collagen protein, citric acid, trehalose, disodium hydrogen phosphate, docusate sodium, an enzyme, ethylic acid, an apple flavor and water.

Owner:CHANGSHA XIEHAOJI BIOENG CO LTD

Method and composition for inhibiting aged skin

ActiveUS10449130B2Accelerate effective transdermal deliveryOptimize allocationHeavy metal active ingredientsCosmetic preparationsGlucose uptakeSkin cell

A method and composition for inhibiting aged skin by topically applying to human skin a topical anti-aging composition. The method involves applying the human skin of afflicted area with an effective amount of the anti-aging composition containing chromium chloride, thiamine mononitrate, magnesium sulfate, and dmae bitartrate for a period of time sufficient to impart the appearance of aged skin. The topical composition is formulated into a pharmaceutically acceptable medium to optimize glucose uptake into the skin cells to properly replace iron production of skin cells, thereby inhibiting the appearance of aged skin.

Owner:RUSS IP HLDG GRP LLC

Micronutrient formulations for radiation applications

A radioactive protection micronutrient formulation system is provided and the system comprises: a formulation consisting essentially of antioxidants, the antioxidants are selected from the group consisting essentially of vitamin C, vitamin E, N-acetyl cysteine, natural mixed carotenoids, and alpha-lipoic acid, vitamin A (palmitate), vitamin D-3 (cholecalciferol), thiamine mononitrate, riboflavin, niacinamide ascorbate, d-calcium pantothenate, pyridoxine hydrochloride, cyanocobalamin, folic acid, D-Biotin, selenium (1-seleno-methionine), chromium picolinate, zinc glycinate, calcium citrate and magnesium citrate and mixtures thereof; and plus a booster formulation selected from a group consisting essentially of vitamin C, d-alpha tocopheryl acid succinate, alpha tocopherol, N-acetyl cysteine, natural mixed carotenoids and alpha lipoic acid, the formulation is designed to reduce the risk in humans exposed to doses of ionizing radiation of becoming subjected to at least one condition selected from the group consisting essentially of radiation-induced acute leukemia, breast cancer, thyroid cancer and other somatic and heritable mutations.

Owner:NEW AGE HEALTH SCI INC

Fodder for promoting black carp quality

InactiveCN106858184AFast growthImprove qualityAnimal feeding stuffAccessory food factorsHalloysiteForsythia

The invention discloses a fodder for promoting black carp quality. The fodder is prepared from the following components in parts by weight: 35-45 parts of shrimp meal, 10-15 parts of ardisia crenata sims, 16-19 parts of tabernaemontana divaricata, 12-14 parts of leek, 18-24 parts of fructus forsythia, 20-25 parts of schisandra chinensis, 19-23 parts of brucea javanica, 6-9 parts of parmelia tinctourium, 2-5 parts of red halloysite, 15-17 parts of spongilla, 13-19 parts of mussel, 10-16 parts of pig spleen, 6-8 parts of swimming bladder, 0.1-0.3 part of thiamine mononitrate, 0.2-0.4 part of sodium polyacrylate and 0.2-0.5 part of L-carnitine fumarate. The fodder provided by the invention is suitable for the black carp which is heavier than 90g and can supply various nutrient substances required by the black carp in a growth process. After the black carp is fed with the fodder for a long time, the growth speed of the black carp can be effectively increased, the quality of the black carp can be effectively improved, and the nutrition value of the black carp can be greatly increased.

Owner:齐芳

Water-soluble vitamin pharmaceutical composition for injection

ActiveCN104382865BQuality assuranceImprove efficiencyPowder deliveryMetabolism disorderSodium lactateVitamin B12

The invention relates to a water-soluble vitamin pharmaceutical composition for injection. The water-soluble vitamin pharmaceutical composition for injection is prepared from 3.1g of thiamine mononitrate, 40g of nicotinamide, 16.5g of sodium pantothenate, 60mg of biotin, 5.0mg of vitamin B12, 0.5g of disodium ethylene diamine tetraacetate, 4.9g of riboflavin sodium phosphate, 4.9g of pyridoxine hydrochloride, 113g of sodium vitamin C, 0.4g of folic acid, 300g of glycine, 0.5g of methyl parahydroxybenzoate, 1.2g of poloxamer 188, 0.5g of sodium lactate, 1.0g of L-malic acid and water for injection, wherein the water for injection is added until the total volume is 2000ml. The water-soluble vitamin pharmaceutical composition for injection, disclosed by the invention, is good in stability and greatly improved in medication safety.

Owner:湖北美林药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com