Method for preparing thiamine hydrochloride crystal product

The technology of thiamine hydrochloride and thiamine nitrate is applied in the direction of organic chemistry method, organic chemistry, etc., can solve the problems such as inability to recycle and apply, increase the process cost, complicated operation steps, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 30g of thiamine nitrate into 150mL of ethyl acetate, stir, and heat to 60°C;

[0032] (2) Weigh 30g of concentrated hydrochloric acid and put it into a multi-port crystallizer, stir, weigh 30g of chlorosulfonic acid and drop it into the concentrated hydrochloric acid, and control the dropping time for 60min, and the generated hydrogen chloride gas is passed into the concentrated sulfuric acid for drying , the dried gas is passed into the suspension in step (1), and the stirring speed is 300r / min;

[0033] (3) After the introduction of hydrogen chloride gas is completed, keep it warm for 20 minutes, then lower the temperature to 10° C. at a rate of 0.1° C. / min, filter, wash, and dry to obtain thiamine hydrochloride crystals.

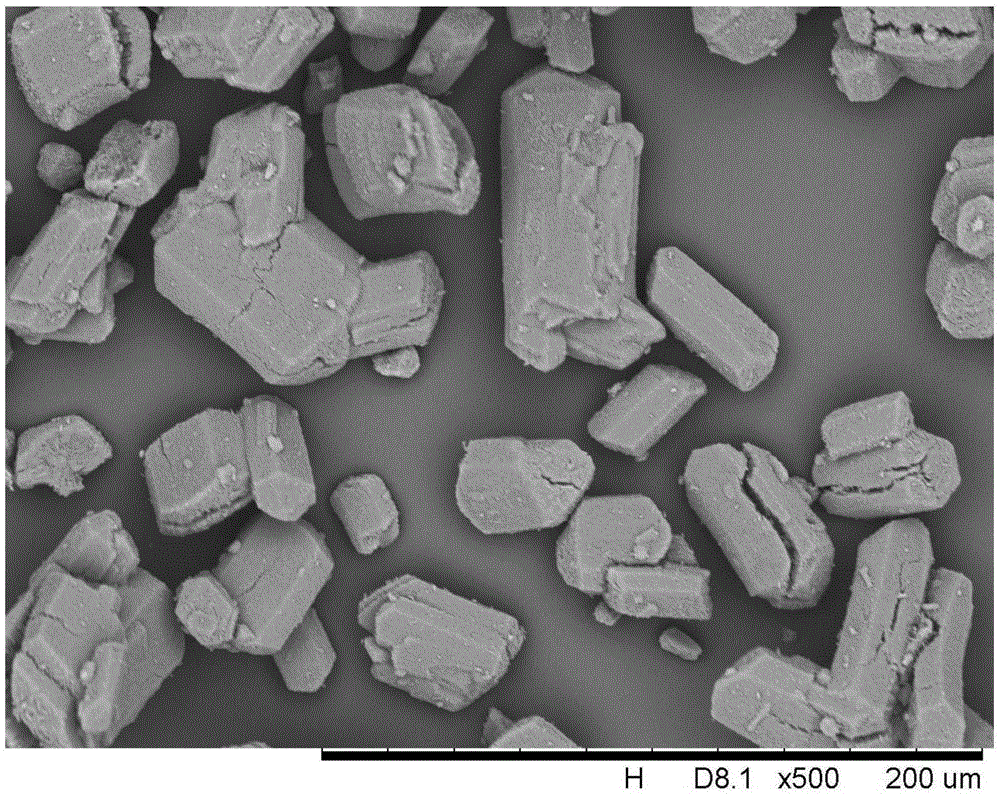

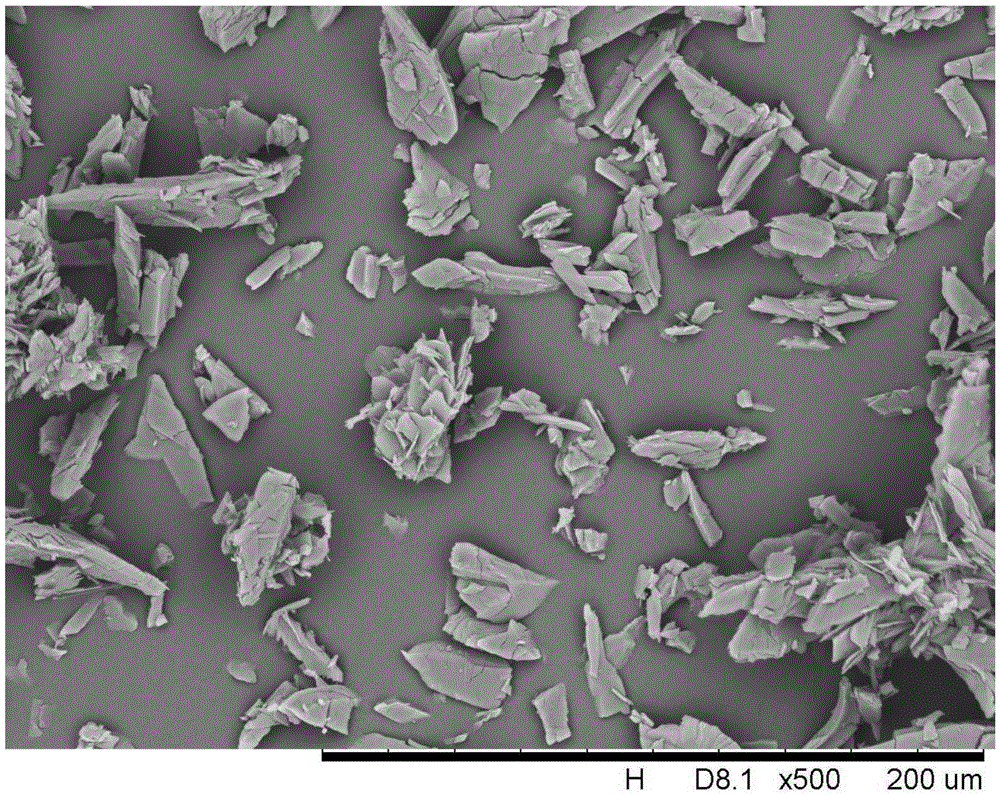

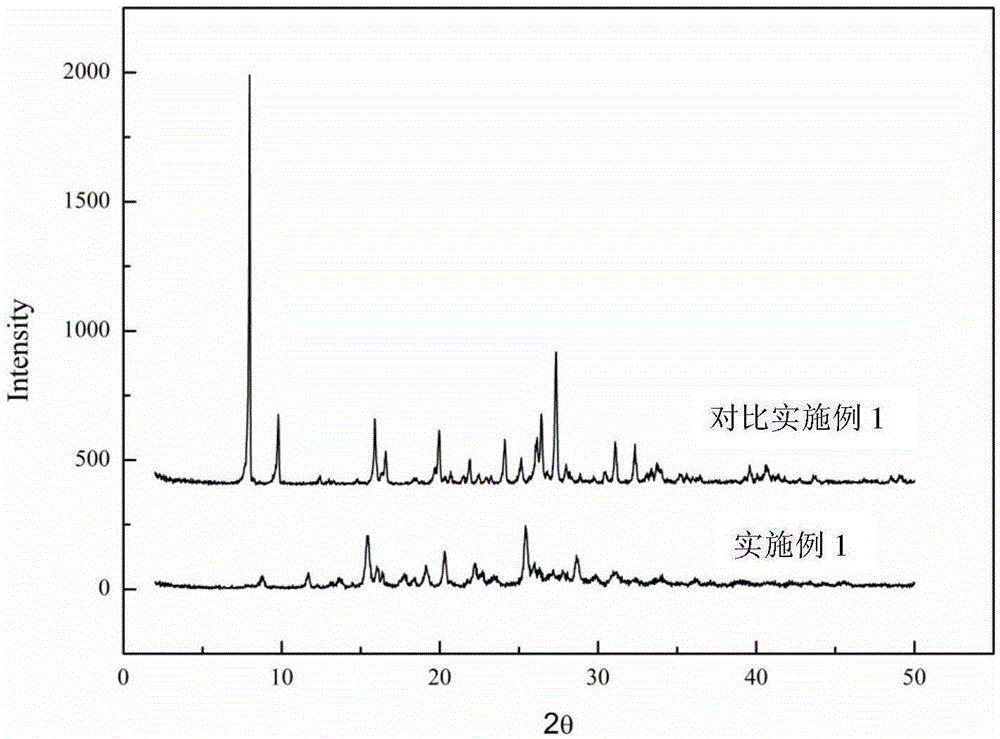

[0034] The obtained product is rod-shaped, and the scanning electron microscope picture is as follows: figure 1 As shown, the X-ray powder diffraction pattern is shown in image 3 shown.

Embodiment 2

[0036] (1) Add 20g of thiamine nitrate into 190mL of ethyl formate, stir, and heat to 50°C;

[0037] (2) take by weighing 20g concentrated hydrochloric acid and put into multi-port crystallizer, stir, take by weighing 20g chlorosulfonic acid and drop in the concentrated hydrochloric acid, control dropwise time is 90min, the hydrogen chloride gas that produces passes into the concentrated sulfuric acid and dries, The dried gas is passed into the suspension in step (1) through the buffer bottle, and the stirring speed is 600r / min;

[0038] (3) After the introduction of hydrogen chloride gas is completed, keep it warm for 15 minutes, then cool down to 10° C. at a rate of 0.3° C. / min, filter, wash, and dry to obtain thiamine hydrochloride crystals.

[0039] The obtained crystals are non-stoichiometric hydrates of thiamine hydrochloride, and the crystal habit is rod-shaped.

Embodiment 3

[0041] (1) Add 20g of thiamine nitrate into 190mL of n-propanol, stir, and heat to 75°C;

[0042](2) take by weighing 20g concentrated hydrochloric acid and put into the multi-port crystallizer, stir, take by weighing 20g chlorosulfonic acid and drop in the concentrated hydrochloric acid, the control dropwise time is 90min, the hydrogen chloride gas that produces passes into the concentrated sulfuric acid and dries, The dried gas is passed into the suspension in step (1) through the buffer bottle, and the stirring speed is 600r / min;

[0043] (3) After the introduction of hydrogen chloride gas is completed, keep it warm for 30 minutes, then lower the temperature to 10° C. at a rate of 0.5° C. / min, filter, wash, and dry to obtain thiamine hydrochloride crystals.

[0044] The obtained crystals are non-stoichiometric hydrates of thiamine hydrochloride, and the crystal habit is rod-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com